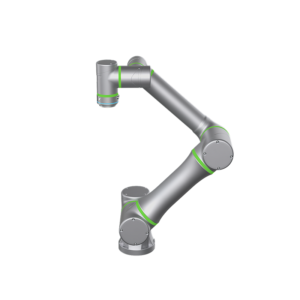

Pick and Place Robot Arms Supplier

EVS offers pick and place robotic arms that can keep up with the demands of modern manufacturing environments. These machines help increase your production output in a cost-effective way through pick and place automation to effectively handle repetitive tasks. Thus, allowing your workers to focus more on complex jobs. As one of the leading pick and place machine manufacturers in China, EVS can help you increase your manufacturing plant’s productivity significantly with consistency through our highly efficient pick and place industrial robots. Reduce placement errors with our robotic arms through a properly integrated system.

EVS Pick and Place Robot Advantages

Well-Knit Design: EVS robots have slender designs which makes them more flexible in small spaces with very low collision rates.

Leak-Proof Structure: Our leak-proof pick & place robots are suitable even for oil-mist and dusty environments.

Easy Installation: With light structure design, they can be easily installed inside your system or mounted upside-down.

EVS Pick and Place Robot Applications

EVS robotic arms can handle various pick and place robot applications from simple to monotonous and repetitive tasks. When strategically positioned, they can provide impressive results for loading, unloading, feeding, packaging, assembly, palletizing, sorting, welding, deburring, and other material handling applications.

EVS Robotics is an industrial robot supplier providing automation solutions and support to our customers. Our products are used in industrial automation such as welding, painting, handling, palletizing, bending and polishing. And after years of development, our core technology has been widely used in different industries like Automotive, Metal Industry, Food & Beverage, Medical & Pharmaceutical and more.

Copyright ©EVS TECH CO., LTD All rights reserved.All materials not authorized may not be redirected or for other usages.