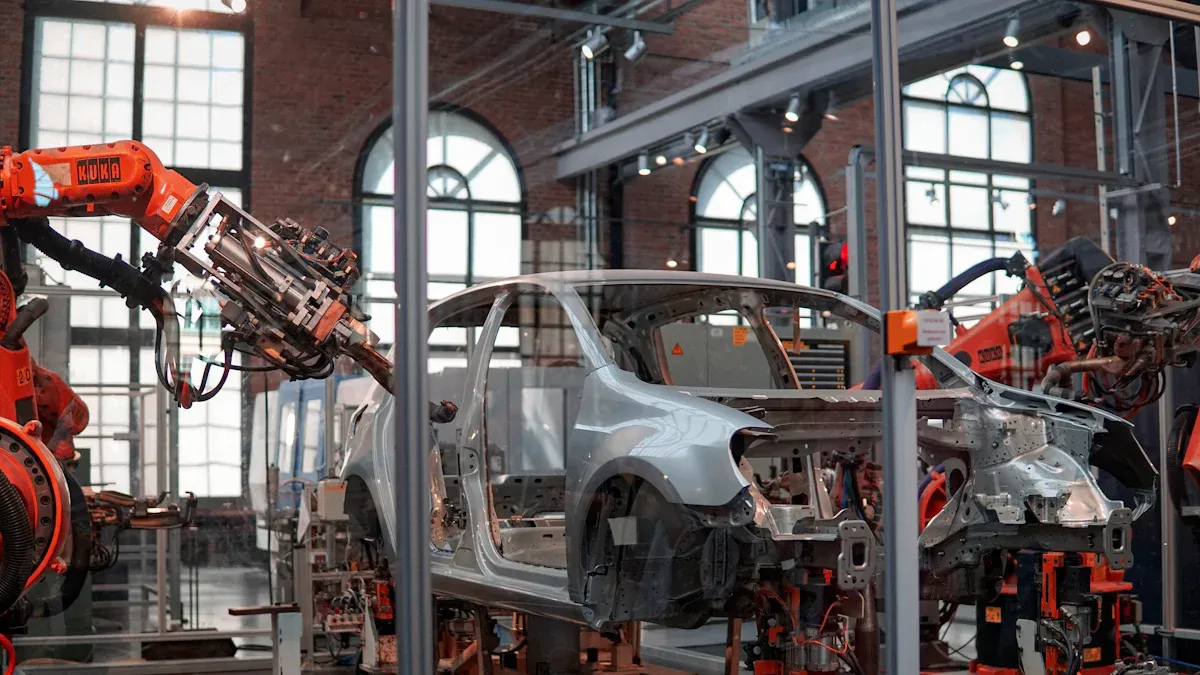

You see robotic arms changing jobs every day. These machines help people work faster and safer. In factories, robotic arms put together cars and electronics very well. Hospitals use them to pack medicines and move things. Food companies use robotic arms to pack and move products. Here is how different industries use robotic arms:

Industry | Usage of Robotic Arms | Impact on Adoption Rate |

|---|---|---|

Electronics | Assembly, inspection, packaging | More devices means more robotic arms used. |

Metal and Machinery | Welding, cutting, material handling | More metal products means more robots used. |

Pharmaceuticals | Packaging, inspection, material handling | More medicine needed means more robots used. |

Food and Beverages | Packaging, palletizing, material handling | More processed food means more robots used. |

Robotic Arms in the Workplace

Productivity Gains

Robotic arms are used in many factories now. They help people finish work faster and make fewer mistakes. You can change what robotic arms do by reprogramming them. This means you can switch jobs on the line quickly. Robotic arms work all day and night without stopping. This helps factories keep making products all the time. You get more things made in less time.

Robotic arms stop human mistakes and keep work steady.

They can adjust to new changes, so you stay on track.

You see fewer broken products and less waste because robotic arms are very exact.

Here are some real examples after companies used robotic arms:

Company | Industry | Result |

|---|---|---|

Plastiform Technologies | Packaging | 30% more products made |

AutoParts Plastics | Automotive | 25% faster work cycles |

MedPlast Solutions | Medical Device Manufacturing | 40% better production efficiency |

Tip: If you want to make more products, robotic arms can help you reach your goals faster.

Safety Improvements

Robotic arms help make jobs safer. You do not have to do dangerous work anymore. Robots do risky jobs like welding or working with chemicals. When you use robotic arms, there are fewer accidents and injuries.

A study in the US and Germany showed that more robots meant fewer injuries. For every 1.34 robots per 1000 workers, injuries went down by about 1.2 for every 100 workers.

Factories had 1.75 fewer injuries for every 100 workers after using robotic arms.

Companies saved $1.69 billion each year because of fewer injuries.

Robots keep you away from danger and help keep you safe.

Many industries have fewer accidents after using robotic arms for hard jobs. Mining and industrial factories now have lower accident numbers because robots do the dangerous work. You can trust robotic arms to help keep your workplace safe.

Changing Job Roles

When robotic arms come to your workplace, your job might change. There may be fewer managers because robots do not make mistakes and need less watching. At the same time, there are more jobs for low-skilled and high-skilled workers. Middle-skilled jobs are not as common now.

Evidence Type | Findings |

|---|---|

Managerial Employment | Fewer managers needed because robots make fewer mistakes. |

Non-Managerial Employment | More jobs for low-skilled and high-skilled workers. |

Skills Requirement | Fewer middle-skilled jobs, new skills needed. |

Decision-Making Authority | Changes in how decisions are made in companies. |

You need new skills to work with robotic arms. Employers want people who know computer science, automation, and data analysis. Many factories need workers with these skills. In fact, 83% of manufacturers have trouble finding skilled workers, and 45% have missed chances because they cannot find the right people. There are 800,000 open jobs in U.S. factories today.

How Do Robotic Arms Work

Structure and Components

A robotic arm looks like it copies your arm. The base holds the arm steady, like your shoulder. Joints let the arm bend and turn, like your elbow and wrist. The end-effector works like your hand. It grabs and moves things. A controller tells the arm what to do, like your brain.

Here is a table that shows the main parts and their jobs:

Component | Function |

|---|---|

Base | Gives the arm a strong base and lets it turn. |

Arm | The main part with joints for movement. |

Wrist | Lets the arm bend and turn in many ways. |

End-effector | The tool at the end, like a hand, that does the work. |

Controller | The robot’s brain, sending commands to move and work. |

You can compare a robotic arm to your own arm. The base is like your shoulder. It gives support. Joints help the arm bend and twist, like your elbow and wrist. The end-effector is like your hand. It grabs and moves things.

Component | Robotic Arm Description | Human Arm Description |

|---|---|---|

Base | The foundation, holds the weight of the arm and what it lifts. | Gives support and keeps the arm steady. |

Joints | Most use turning joints, some use sliding joints for straight movement. | Shoulder and elbow joints let your arm move in many ways. |

End Effector | Tool at the end for doing tasks. | Hand, which grabs and does many jobs. |

Movement and Control

Special systems and sensors control a robotic arm. The controller sends signals to motors in the joints. These motors move the arm, wrist, and end-effector. Sensors help the robot know where it is and how hard it pushes. Motion sensors track how the arm moves. Pressure sensors check how hard the arm presses. Force sensors measure how strong the arm is.

Here are the steps for how robotic arms work:

Programming: You tell the robot what to do.

Control: The controller reads your program and sends signals.

Movement: Motors move the arm based on the signals.

Feedback and Adjustment: Sensors help the robot stay accurate.

End-effector Action: The end-effector does the job, like picking up something.

Modern robotic arms use advanced control systems. These systems help the arm move smoothly and safely. Motion control guides the arm’s path. Force control helps the arm push or pull with the right strength. Hybrid motion-force control helps the arm write or press on things. Impedance control makes the arm act like it has springs or weights, so it is safer with people.

Control System Type | Description |

|---|---|

Motion Control | Guides how the robot arm moves. |

Force Control | Makes the arm push or pull with the right force. |

Hybrid Motion-Force Control | Moves and pushes at the same time, like writing on a board. |

Impedance Control | Makes the arm act like it has springs or weights for safety. |

Sensors make the robot smarter. Tactile sensors help the robot feel objects. This is important for careful work. Vision systems use cameras and lasers to see and check things.

Kinematics is a big part of how robotic arms work. Kinematics helps you know where the arm and end-effector are. Forward kinematics finds the position from the joint angles. Inverse kinematics sets the joint angles for a certain spot. This helps the robot move smoothly and pick up things exactly.

Kinematics Type | Description |

|---|---|

Forward Kinematics | Finds the end-effector’s spot from the arm’s joint angles. |

Inverse Kinematics | Figures out the joint angles needed for a certain spot. |

Kinematics helps the arm and end-effector move smoothly.

You get exact spots for picking up and putting down things.

Types of Robotic Arms

There are many types of robotic arms in factories and labs. Each type is good for different jobs.

Type of Robot | Characteristics | Applications |

|---|---|---|

SCARA | Has three axes and moves side to side fast. | Used for assembly, stacking, and medical jobs. |

Articulated | Looks like a human arm, has many joints, usually four or six. | Used for assembly, welding, moving things, and packing. |

Cartesian | Moves straight along three axes, strong for heavy loads. | Used for machines, 3D printing, and assembly. |

Collaborative (COBOTS) | Works with people, safe for teamwork. | Used for factory jobs and surgery. |

SCARA robots move fast from side to side. They are good for assembly and medical jobs.

Articulated robots look and move like human arms. You see them in factories for welding and packing.

Cartesian robots move straight along three lines. They lift heavy things and do careful work like 3D printing.

Collaborative robots, or COBOTS, work with people. They are used where safety and teamwork are important.

Articulated arms are the most common in factories. They have many joints, so they can move in many ways. The six-axis articulated arm is very flexible. It is good for welding, moving things, and picking up items. Its design copies the human arm, so it is used for many jobs.

If you want to learn more about robotic arms, look at how each type moves and what jobs they do. You will see that the way a robot arm works depends on its type and job.

Industry Uses

Manufacturing

Robotic arms are used a lot in manufacturing. They help weld car frames and put together electronics. These machines also move heavy things. Robotic arms work quickly and do not get tired. They make strong welds and put things together very well.

In car and airplane factories, robotic arms do welding. This makes welds strong and exact.

You can use them to move heavy stuff and do the same job over and over.

Pick and place robots help load and unload machines. They also sort and organize parts.

These machines work fast and keep the quality the same each time.

Robotic arms help you work better and faster. They do simple jobs so you can do harder ones. They also make your job safer by doing dangerous work.

Medical

Robotic arms have changed how doctors do surgery. You can see them in operating rooms helping doctors with hard surgeries. These systems help doctors be more careful and in control.

Robotic surgery means fewer problems and better results for patients.

Doctors use robotic arms for hard jobs like working on blood vessels and lymph nodes.

Good 3D pictures help doctors see better and work safely.

Studies show robotic arms lower problems and help people leave the hospital sooner. For example, using AI robotic arms in spine surgery made problems drop from 12.2% to 6.1%. Patients heal faster and do not stay in the hospital as long.

Safety and Defense

Robotic arms help keep people safe in dangerous jobs. Bomb robots use robotic arms to handle bombs from far away.

Feature | Description |

|---|---|

Dexterity | Almost like a human arm but stronger |

Functionality | Can grab and move things with easy controls |

Application | Used for bomb work and handling dangerous materials |

These robots use water jets to make bombs safe. You control them from far away, so you are not in danger. They can cut wires and get past things in the way. In the army and factories, robotic arms clear mines, move toxic stuff, and watch over dangerous places.

Collaborative Robots

Collaborative robots, called cobots, work next to people. You see cobots in factories, labs, and hospitals. Cobots do boring or risky jobs so you can do safer and more creative work.

Cobots change how you work with machines and make your job safer.

They lower risks and let you do harder jobs.

Cobots can work in new places and help you get more done.

When you use cobots, your job is safer and you work better. These robots help you and make it easier to reach your goals in many jobs.

Advantages and Challenges

Benefits

Robotic arms give you many good things at work. These machines work all day and night. They do not need breaks. You can trust them to keep making products. Robotic arms finish boring jobs fast and very carefully. You get more products in less time.

Robotic arms keep working, so production does not stop.

They are very accurate, even to tiny amounts.

You get the same quality every time, even after many tries.

You can add more robotic arms when you need to make more.

Robots do not get tired, so work goes faster.

Special force control helps with gentle jobs.

Robotic arms also help you save money and work better. Here is how these machines help your business:

Contribution Type | Description |

|---|---|

Lower Labor Costs | Robots do boring jobs, so you pay less for workers. |

Minimized Waste | Robots make fewer mistakes and save materials. |

Energy Efficiency | New robots use less energy, so bills go down. |

Predictive Maintenance | Smart robots find problems early, so repairs cost less. |

24/7 Operations | Robots work all the time, so you make more things. |

Precision & Accuracy | Robots make fewer errors and better products. |

Speed & Productivity | Robots make your lines move faster. |

Integration with AI & IoT | Smart robots use data to keep things running well. |

Challenges

You may have some problems when you use robotic arms at work. Sometimes, you need to change your old systems for new robots. Workers must learn how to use and fix these machines. Old machines may not work with new robotic arms, which can slow things down.

You might need to change how you work to fit robots.

Training your team takes time and work.

Some old machines do not connect well with new robots.

You must follow safety rules and laws.

Changing how your team works is important too. Many companies see happier workers after using robots, but some people feel less control. In places with lots of robots, workers can feel 7.5% less free. You can help by making people and robots work together, keeping human jobs clear, and teaching new skills.

Future Trends

AI Integration

Artificial intelligence is changing how robotic arms work. AI helps robots learn from what is around them. Robots can make smart choices on their own. They can switch jobs and train themselves. Robots help doctors in hospitals too. Look at the table below to see how AI helps robotic arms:

Role of AI in Robotic Arms | Description |

|---|---|

Intelligence and Autonomy | AI lets robots learn from their environment and make hard choices quickly. |

Precision and Decision Making | AI helps robots use information to do tasks very carefully. |

Predictive Maintenance | Robots check how they work and can spot problems before they happen. |

Self-Training | Robots teach themselves with AI, so people do not have to program them as much. |

Role Switching | AI lets robots change jobs, like picking crops or building things. |

Assistance in Healthcare | AI robots help with surgery, find diseases, and care for older people well. |

Soft Robotics

Soft robotics brings new ways to build robotic arms. These arms are flexible and light. They can bend and stretch. Soft robotic arms move in many directions. They get past things better than stiff robots. Some arms use shapes like origami to reach farther. They work safely with people, even those in wheelchairs. Special materials and smart computer programs help these robots do gentle jobs and work in different places.

Edge Computing

Edge computing helps robotic arms react fast. Robots use real-time data to make quick choices. They process information right where they work. Robots do not need to wait for cloud servers. This means less waiting and better safety. Robotic arms keep working even if the internet stops.

Cuts down waiting time, so robots make choices faster.

Makes robots more reliable because they do not need the network.

Keeps data safe by handling it close to the robot.

Modular Design

Modular design lets you change robotic arms easily. You can swap parts and tools for new jobs. This saves time and money when you need to do something different. In factories, you can use new end-effectors for welding or building things. Hospitals use modular tools for many medical jobs. Self-driving cars add new sensors and features to work better.

Manufacturing Robots: Modular arms with changeable end-effectors help factories switch jobs fast and work better.

Healthcare Robotics: Modular designs let hospitals use different tools for many jobs, helping patients and saving money.

Autonomous Vehicles: Modular platforms let cars add new sensors and parts, so they work better in many ways.

Modular robotic arms help you keep up with changes and make upgrades easy.

You see robotic arms making work faster, safer, and more accurate. These machines help you finish tasks and keep you away from danger. You face new challenges, like learning new skills and working with technology. Looking ahead, robotic arms will learn and grow, working with you in more places.

The market for robotic arms may reach over $22 billion by 2028, with new jobs in healthcare, electronics, and farming.

As costs drop, you will see robotic arms in small businesses and schools.

Think about how robotic arms could change your job or industry in the next few years.