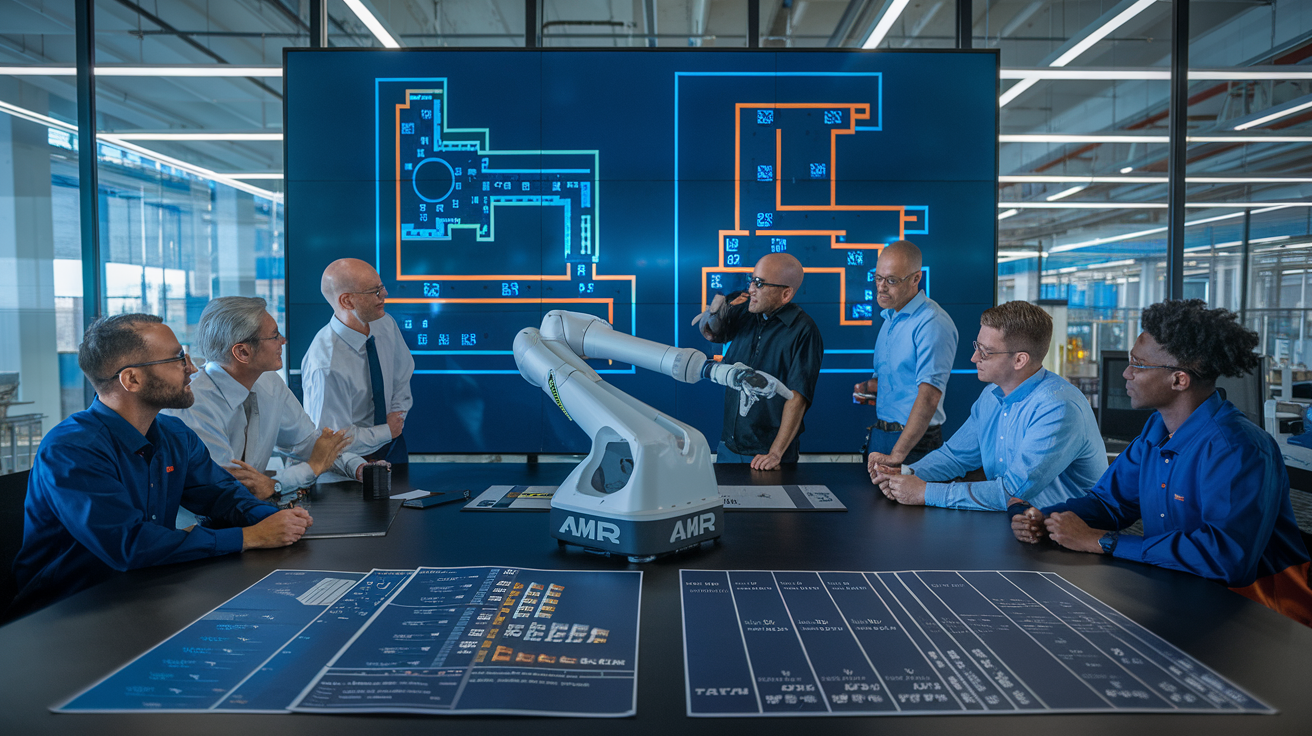

You’re staring at a $250,000 mobile robot that’s supposed to revolutionize your factory floor. But right now? It’s just sitting there, completely disconnected from everything else in your facility.

This is the exact moment when most manufacturing integration projects go sideways. Your existing systems weren’t built to talk to these autonomous mobile robots (AMRs), and now you’re facing what feels like an impossible puzzle.

In this guide, we’ll walk through exactly how to integrate autonomous mobile robots with your existing manufacturing systems without tearing everything apart and starting over. You’ll get practical steps that work whether you’re dealing with legacy equipment from the 90s or a mostly-modern setup.

The difference between successful AMR integration and expensive warehouse decoration comes down to five critical decisions. The first one might surprise you…

Understanding the Role of AMRs in Modern Manufacturing

Key benefits of autonomous mobile robots in production environments

AMRs are changing the game in manufacturing, and for good reason. These smart machines aren’t just cool tech – they deliver serious value where it matters most.

First off, they slash labor costs while boosting productivity. Your workers aren’t wasting time pushing carts around; they’re focusing on skilled tasks that actually need human touch.

Safety improvements are major too. AMRs handle dangerous, repetitive transport jobs so your team avoids injuries and strain. They navigate crowded floors without accidents – something traditional AGVs just can’t match.

Flexibility is where AMRs truly shine. Unlike fixed conveyor systems, these robots adapt on the fly. Need to reconfigure your production line? No problem. AMRs adjust their routes without costly downtime or rewiring.

The data piece is huge as well. Modern AMRs collect operational insights that help you spot bottlenecks and optimize workflows continuously.

Comparing AMRs to traditional automation solutions

| Feature | AMRs | Traditional AGVs/Conveyors |

|---|---|---|

| Navigation | Dynamic mapping, obstacle avoidance | Fixed paths, magnetic strips/wires |

| Setup time | Hours/days | Weeks/months |

| Adaptability | Route changes on demand | Requires physical reconfiguration |

| Intelligence | Autonomous decision-making | Preprogrammed paths only |

| Scalability | Add units as needed | Major infrastructure changes |

Real-world success stories and ROI examples

A major automotive manufacturer deployed 15 AMRs and cut material transport costs by 40% in just 8 months.

An electronics assembly plant integrated AMRs with their existing ERP system and saw a 28% increase in throughput with 30% less floor space dedicated to WIP storage.

Most companies see full ROI within 12-18 months, dramatically faster than traditional automation solutions that might take 3-5 years to pay off.

One distribution center reduced pick-travel time by 62% when they paired AMRs with their legacy warehouse management system – without modifying their existing racking infrastructure.

Assessing Your Manufacturing System’s Readiness

Conducting a comprehensive workflow analysis

Getting Autonomous Mobile Robots (AMRs) to play nice with your factory setup starts with knowing exactly how your operations tick. Map out every single workflow—from raw materials coming in to finished products going out.

Look closely at:

-

Material handling paths and bottlenecks

-

Worker movement patterns

-

Current equipment usage rates

-

Cycle times for key processes

-

Seasonal fluctuations in production

Don’t just rely on your documented processes. What’s on paper rarely matches reality. Walk the floor, talk to operators, and watch actual workflows. You’ll spot inefficiencies that don’t show up in reports.

Identifying integration pain points and opportunities

Truth bomb: not every process needs robots. Some parts of your operation will benefit enormously from AMRs, while others might actually get worse.

Pain points that scream for AMR integration:

-

Repetitive transport tasks eating up labor hours

-

High-traffic areas causing congestion

-

Processes with consistent wait times between steps

-

Safety-critical movements of hazardous materials

Opportunity areas often include:

-

Material transport between workstations

-

Warehouse picking and kitting operations

-

Just-in-time delivery to production lines

-

End-of-line packaging support

Evaluating existing infrastructure compatibility

Your building itself might fight against your AMR dreams. Check these physical elements:

-

Floor surfaces: Cracks, transitions, and slopes can trip up robots

-

Wi-Fi coverage: Dead zones will strand your AMRs

-

Doorways and aisles: Too narrow? Your robots can’t pass

-

Elevator integration: Need special protocols for multi-floor operations

-

Charging station locations: Power availability dictates placement

Determining technical requirements and specifications

Before shopping for AMRs, create your must-have list:

-

Payload capacity requirements

-

Operating time needs between charges

-

Navigation technology preferences (QR codes, natural features, magnetic tape)

-

Safety certification requirements

-

Integration capabilities with your MES or ERP systems

-

Communication protocols needed for machine interactions

Think about your future needs too. The AMR system you implement should scale with your forecasted growth over the next 3-5 years.

Planning Your AMR Integration Strategy

Planning Your AMR Integration Strategy

A. Setting clear automation objectives and KPIs

Before jumping into AMR implementation, you need to know exactly what you’re trying to fix. Are you aiming to reduce material transport time? Cut labor costs? Improve safety?

Pick specific, measurable goals like:

-

Decrease travel time between workstations by 30%

-

Reduce manual transport labor by 25%

-

Lower product damage rates by 15%

-

Improve on-time delivery by 20%

These aren’t just fancy numbers to impress management. They’re your roadmap. If your AMRs aren’t hitting these targets after implementation, you’ll know something’s off.

B. Selecting the right AMR models for your specific needs

Not all Autonomous Mobile Robots are created equal. The factory floor isn’t a one-size-fits-all environment.

Consider these factors when choosing:

-

Load capacity requirements (50kg vs 1500kg makes a huge difference)

-

Navigation needs (open spaces or narrow aisles?)

-

Speed requirements (how fast do materials need to move?)

-

Battery life (24/7 operation or occasional use?)

-

Integration capabilities with your WMS or MES systems

Talk to multiple vendors. Get demos. Put the robots through real-world tests in your actual environment before committing.

C. Creating a phased implementation roadmap

Nobody implements AMRs everywhere overnight. Smart manufacturers start small and expand.

A typical phased approach looks like:

-

Pilot phase: Single application, limited area, 1-2 robots

-

Targeted expansion: Add 3-5 more robots, cover key production areas

-

Full implementation: Plant-wide deployment with complete workflow integration

Each phase should have clear milestones and evaluation periods. Don’t rush to the next phase until you’ve worked out the kinks in the current one.

D. Budgeting for total cost of ownership

The sticker price of AMRs is just the beginning. Your budget needs to account for:

-

Initial robot purchase/lease costs

-

Infrastructure modifications (charging stations, Wi-Fi enhancements)

-

Software integration expenses

-

Training for operators and maintenance staff

-

Ongoing maintenance and support contracts

-

Potential production disruption during implementation

Calculate ROI over a 3-5 year period for a realistic picture. The upfront costs might make you sweat, but the long-term savings often justify the investment.

Preparing Your Physical Environment

Optimizing facility layout for AMR traffic

Picture this – you’ve invested in fancy Autonomous Mobile Robots (AMRs) but your factory floor looks like an obstacle course. That won’t work.

Start by mapping your current workflow patterns. Where do people walk? Where do materials flow? Your AMRs need clear, consistent paths without constantly navigating around random obstacles.

Remove unnecessary equipment and create dedicated AMR lanes at least 4-5 feet wide. Mark these lanes clearly with floor tape or paint – both humans and robots need to know where the robot highways are.

Think about bottlenecks too. Those narrow passages between workstations? They’re AMR traffic jams waiting to happen. Widen them or reroute your robot paths completely.

Establishing charging station locations and power requirements

Your AMRs are only as good as their battery life. Place charging stations strategically:

-

Near high-traffic areas where robots frequently pass

-

Away from production bottlenecks or congested zones

-

Close to power sources (seems obvious, but often overlooked)

-

Distributed evenly throughout your facility

Most AMRs require standard 110V outlets, but check your specific models. You’ll need approximately one charging station for every 2-3 robots in your fleet. And always factor in growth – add 20% more charging capacity than you currently need.

Implementing necessary safety measures and protocols

Safety isn’t optional with AMRs. Here’s what you need:

-

Emergency stop buttons placed throughout your facility

-

Visual and audio signals when AMRs are in motion

-

Clear signage in robot traffic areas

-

Designated “robot-free” zones where needed

Train your staff thoroughly on AMR interaction protocols. They should understand robot behavior patterns, priority rules at intersections, and what to do if a robot malfunctions.

Regular safety audits are critical – check that sensors are working properly and obstacle detection is functioning as expected.

Tackling Technical Integration Challenges

A. Connecting AMRs with existing MES and ERP systems

The trickiest part of bringing Autonomous Mobile Robots into your factory? Getting them to play nice with your Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software. These systems weren’t exactly built with robots in mind.

Start by mapping out every single data exchange point. Your AMRs need to know what to make, where to go, and when to do it—all of which comes from your MES. Meanwhile, your ERP needs accurate inventory updates as robots move materials around.

Most modern AMRs come with integration tools, but they’re rarely plug-and-play. You’ll likely need custom connectors that translate between your legacy systems and the robot’s communication protocols. Some manufacturers find success using middleware platforms specifically designed for industrial automation integration.

B. Setting up reliable network infrastructure and connectivity

Your Autonomous Mobile Robots are only as good as your network. A dropped connection can mean a stopped robot—or worse, a safety issue.

Wi-Fi dead zones? Not an option. You’ll need:

-

Industrial-grade access points with overlapping coverage

-

Dedicated VLAN for robot traffic

-

QoS settings that prioritize robot command and control data

-

Redundant network paths wherever possible

Bandwidth requirements might shock you. Each robot continuously streams telemetry, receives commands, and often uploads visual data. A fleet of 10 AMRs can easily saturate a poorly designed network.

C. Developing APIs and middleware solutions

Few manufacturing environments can directly connect their existing systems to AMRs without some middleware magic. Your options:

-

Use vendor-provided APIs (if they exist)

-

Develop custom middleware that acts as a translator

-

Implement an IoT platform designed for industrial integration

The middleware approach often wins because it creates a buffer between your critical systems and the robots. This means you can update either end without breaking the whole chain.

Your middleware should handle:

-

Protocol translation

-

Message queuing when systems are temporarily offline

-

Data transformation between formats

-

Basic decision routing for simple robot tasks

D. Ensuring cybersecurity compliance and data protection

Robots add new attack surfaces to your manufacturing environment. Each AMR is essentially a mobile computer with physical capabilities—a security nightmare if not properly locked down.

Basic security measures to implement:

-

Encrypted communications for all robot traffic

-

Regular firmware updates and patch management

-

Network segmentation to isolate robot operations

-

Strong authentication for robot management interfaces

-

Intrusion detection systems that understand normal robot behavior patterns

Don’t forget regulatory compliance. Depending on your industry, you may need to document how robot-collected data is stored, processed, and protected.

E. Testing integration points before full deployment

Never, ever roll out integrated AMRs without thorough testing. Create a staged testing environment that mimics your production setup:

-

Start with isolated systems testing each integration point

-

Progress to controlled scenarios with limited robot operations

-

Simulate failure modes (network drops, system crashes)

-

Conduct load testing with multiple robots operating simultaneously

-

Run extended duration tests to catch intermittent issues

Document every test case and result. When issues arise (and they will), this documentation becomes invaluable for troubleshooting. Consider bringing in specialized integration consultants who’ve done this before—they’ve already made the mistakes you’re trying to avoid.

Training Your Workforce for the AMR Era

A. Developing new skill sets for operations and maintenance teams

Your team isn’t just working with another piece of equipment – they’re partnering with intelligent machines that think and adapt. That’s a whole different ballgame.

Start by identifying the technical skills needed to operate your Autonomous Mobile Robots. Your maintenance staff need basics like robot startup/shutdown, mission assignment, and basic troubleshooting. Don’t overlook data interpretation skills – AMRs generate valuable operational insights that can boost your productivity.

Cross-training is essential. When Sarah from shipping understands how the AMR navigation works, she can quickly spot when something’s off before it becomes a problem.

B. Creating clear roles and responsibilities

Who’s in charge when the robot stops in the middle of a task? Without clear ownership, problems linger.

Create a simple responsibility matrix with these roles:

-

AMR Supervisors: Oversee daily operations and robot scheduling

-

Technical Specialists: Handle diagnostics and complex troubleshooting

-

Floor Workers: Basic interaction and first-level problem reporting

Update your standard operating procedures to reflect who does what when working alongside AMRs. This clarity eliminates the “not my job” response when issues arise.

C. Fostering human-robot collaboration mindsets

The biggest hurdle? It’s not technical – it’s psychological. Many workers worry robots will replace them.

Shift the conversation from “robots versus humans” to “robots supporting humans.” Share examples of how AMRs handle repetitive tasks so workers can focus on more skilled activities.

Celebrate early wins and involve skeptical team members in the implementation process. Nothing builds confidence like seeing results firsthand.

Deployment and Optimization

Implementing a pilot program with measurable outcomes

Starting small is your secret weapon. Pick one production area where Autonomous Mobile Robots (AMRs) can make an immediate impact—maybe it’s materials transport or inventory management.

Set clear metrics before you begin:

-

Cycle time reduction

-

Labor hours saved

-

Error rate changes

-

ROI timeline

Don’t just track the obvious. Monitor employee acceptance and workflow disruptions too. The numbers tell only half the story.

Scaling from pilot to full implementation

Got promising pilot results? Great! Now take a breath before going all-in.

Expand in phases—maybe one department or shift at a time. This gives your team space to adapt and prevents system-wide hiccups. Your pilot probably revealed some surprises (they always do). Address these lessons before scaling up.

Create a detailed rollout calendar with buffer time built in. Trust me, you’ll need it.

Continuous monitoring and performance tuning

AMRs aren’t “set and forget” technology. The real magic happens when you fine-tune them based on actual performance data.

Track how your robots interact with:

-

Physical environment changes

-

Peak production periods

-

New product introductions

Collect feedback from operators weekly, not quarterly. They’ll spot inefficiencies you’d never notice from management reports.

Establishing maintenance protocols and support systems

Downtime kills ROI faster than anything. Create two maintenance tracks:

-

Preventative: Schedule regular checks based on manufacturer recommendations and your specific usage patterns

-

Responsive: Develop clear escalation procedures for when (not if) something goes wrong

Train multiple team members as robot champions. When your only AMR expert calls in sick during a major malfunction, you’ll thank me.

Implementing Autonomous Mobile Robots into your manufacturing systems requires careful planning and execution, but the rewards are substantial. By following the steps outlined in this guide—from assessing your facility’s readiness to optimizing deployment—you can minimize disruption while maximizing the benefits these technologies offer. Remember that successful integration balances technical considerations with workforce preparation, ensuring your team is equipped to work alongside these new robotic colleagues.

As you move forward with your AMR implementation, maintain a continuous improvement mindset. The initial deployment is just the beginning of your automation journey. Regularly evaluate performance metrics, gather feedback from operators, and stay informed about emerging AMR capabilities. With the right approach, AMRs won’t just automate tasks—they’ll transform your manufacturing operations, driving efficiency, quality, and competitiveness in an increasingly automated industrial landscape.