Choosing the right painting robots in 2025 can make or break your production. You need to think about your workload, coating style, and budget. New tech like AI, vision systems, and cobots bring more options, but they also add complexity. Many buyers make mistakes by skipping key steps:

You might forget to define your needs, like the size and complexity of items you want to paint.

Sometimes you miss out on checking robot manufacturers with strong support.

You could overlook integration with your current setup.

Training and support matter more than you think.

Focusing only on painting robot prices 2025 can lead to poor decisions.

Planning for future growth helps you stay ahead.

You want smart solutions, not surprises.

Key Factors for Painting Robots

Robot Types

When you start looking at painting robots, you will see several types. Each type works best for different jobs. Picking the right one helps you get better results and saves money. Here is a quick guide to the main types you will find in 2025:

Type of Robot | Description | Applications |

|---|---|---|

Six-axis articulated arms | Six joints for flexibility and precision in complex shapes. | Great for cars, planes, electronics, and hard-to-reach spots. |

Four-axis robots | Simple, strong, and good for straight-line painting. | Best for flat or gently curved surfaces and basic jobs. |

SCARA robots | Fast and perfect for small, repeated tasks with a limited range. | Used for electronics and small appliance parts. |

You can also choose between traditional industrial robots and collaborative robots (cobots). Cobots work safely next to people. They have special safety features, so you do not need big safety fences. Cobots are easy to reprogram and move around. This makes them great for shops that change jobs often. Traditional robots move faster and handle big jobs, but they need more space and safety barriers.

Features

Painting robots in 2025 come packed with new features. These upgrades help you get better quality, save time, and lower costs. Here are some of the top features you should look for:

AI and computer vision give robots “eyes” and “brains.” They spot obstacles like doors and windows, plan the best path, and avoid bumps.

Vision systems help robots see depth. This means they can paint at different heights and angles without missing a spot.

AI can match human accuracy and even beat human inspectors for quality. It finds defects again and again, so you get the same high quality every time.

AI-vision software can adjust to changes in shape, color, or lighting. Your process stays stable, even if things change.

Robots with AI can work all day and night. They keep your production going, even if you have fewer workers.

High-precision robots use less paint. This cuts waste and helps the environment.

Energy-saving features lower power use by 12% to 25%. This saves you money and helps you meet green rules.

Setup and Support

Getting the right painting robots is only the first step. You also need good setup and support. Top robot makers offer strong training and help. This makes sure your team can run, fix, and update your robots with confidence.

Training Aspect | Description |

|---|---|

Comprehensive Training | Teaches everyone how to use, program, and care for painting robots. |

Safety Procedures | Shows how to stay safe while using robots. |

Troubleshooting | Helps you fix common problems fast. |

Refresher Training | Keeps your team up to date with new skills. |

New Model Training | Gives extra help when you get new robots or software. |

Autonomy in Management | Lets you manage your own painting robots without always calling for help. |

Electrical and Mechanical | Covers both the electrical and mechanical sides of the robots. |

Programming Training | Teaches you how to program robots for different jobs and use vision systems. |

When you pick painting robots, think about the type, the features, and the support you will get. This helps you get the best results for your shop and keeps your team happy and safe.

Painting Robot Prices 2025

When you start shopping for painting robots, you will notice a wide range of prices. The right choice depends on your needs, your budget, and the type of work you do. Let’s break down painting robot prices 2025 so you know what to expect.

Total Cost of Ownership

Maintenance

When you buy a painting robot, you pay more than the price tag. You need to plan for yearly maintenance. This means you will replace old parts and get regular service. You also need to update software. You spend money on paint refills and other supplies. If you skip these steps, your robot might break or stop working well.

About 20% of your robot’s cost goes to maintenance.

If your robot costs $100,000, you will spend $20,000 on upkeep.

These costs include labor, parts, downtime, and service contracts.

Integration

Making your painting robot work with your setup can be hard. You need to think about motion planning and fixing problems. Your robot must fit in your workspace. Sometimes, robots do not work with old software or hardware. You may need upgrades to make things work together.

Motion planning helps your robot paint well on different surfaces.

Fixing problems can slow you down if something breaks or paint is wasted.

Things like humidity or heat can change how your robot works.

Software and hardware must match for smooth integration.

If you plan ahead, you can stop most problems. Good integration means less downtime and better results.

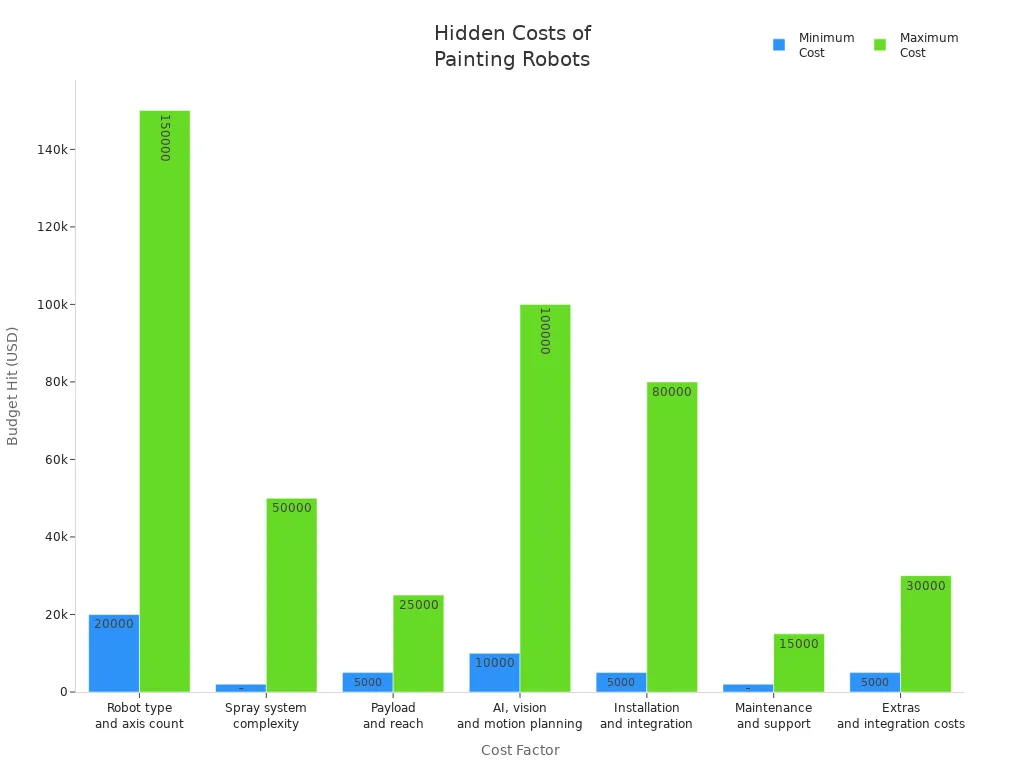

Hidden Costs

You might see a low price at first, but hidden costs can add up fast. These costs include extra features, installation, and special sprayers. Maintenance and support also add to your spending. Over three to five years, you should expect to pay 10–20% more than the price you paid.

Factor | Budget hit |

|---|---|

Robot type and axis count | $20K–$150K+ |

Spray system complexity | $2K–$50K |

Payload and reach | $5K–$25K |

AI, vision, and motion planning | $10K–$100K |

Installation and integration | $5K–$80K+ |

Maintenance and support | $2K–$15K/year |

Extras and integration costs | $5,000 – $30,000+ |

If you look at everything, you will see that total cost of ownership is more than just buying the robot. You need to plan for maintenance, integration, and hidden costs. This helps you make smart choices and get the most from your robot.

New vs. Used Painting Robots

Pros and Cons

You might wonder if you should buy a new painting robot or save money with a used one. Both choices have clear upsides and downsides. Here’s a quick look to help you decide:

Type | Price Range | Pros | Cons |

|---|---|---|---|

Used Robot | $5K–$32K | Big upfront savings, quick delivery | Older units may lack AI, safety upgrades, etc. |

New Robot | $100K+ (conservatively) | Modern safety, reliability, and technology | Higher initial investment |

A used robot can save you a lot of money right away. You can get it fast, which helps if you need to start painting soon. Many shops pick used robots when they want to cut costs or try out automation for the first time.

But used robots often miss out on the latest features. You might not get smart AI, new safety systems, or energy-saving tools. Sometimes, older robots need more repairs or don’t fit well with your current setup. You may also have trouble finding support or spare parts.

A new robot costs more, but you get the latest tech. You also get better safety, more reliable performance, and full support from the maker. If you want to future-proof your shop, a new robot is the safer bet.

When to Buy Used

You should think about a used painting robot if you want to save money and get started quickly. Used robots work well for simple jobs or as backup units. If your team knows how to fix and set up robots, you can handle small issues that come with older models.

Used robots also make sense if you want to test automation before making a big investment. You can learn what works for your shop without spending a lot. If you only need basic painting and don’t care about the newest features, a used robot can do the job.

Best Paint Shop Robots

Top Brands

If you want the best paint shop robots, you should look at the top brands first. These companies lead the way in technology and support. You will see names like FANUC, ABB, Yaskawa, Dürr, and Standard Bots (RO1) in almost every list of best paint shop robots. Each brand brings something special to the table.

FANUC robots work fast and last a long time. You can trust them for tough jobs.

ABB offers smart robots with easy controls. You get smooth painting and less waste.

Yaskawa makes robots that fit many industries. They move quickly and paint with high precision.

Dürr focuses on automotive painting. Their robots give you high-quality results for car bodies and parts.

Standard Bots RO1 stands out as one of the budget-friendly picks. You get smart features without breaking the bank.

Leading Models

Now, let’s look at some leading models. You want robots that match your needs and give you the best paint shop robots experience. Here are some picks you should know about:

Robot Model | Speed | Accuracy | Flexibility |

|---|---|---|---|

YASKAWA Painting Robots | High-speed | High precision | Suitable for various industries |

Universal Robots RO1 Model | Exceptional | Intuitive operation | Accessible for users with minimal expertise |

Yaskawa painting robots help you finish jobs quickly. You get precise lines and smooth finishes. Universal Robots RO1 makes painting easy for everyone. You do not need special skills to run it. This model is perfect if you want simple controls and flexible use.

FANUC’s paint robots handle large parts and tough coatings. ABB’s models use smart sensors to adjust for every surface. Dürr robots shine in car factories, giving you the best paint shop robots for automotive work. Standard Bots RO1 is one of the best paint shop robots for small shops and new users.

Choosing Paint Shop Robots

Matching Needs

You want paint shop robots that fit your application and budget. Start by looking at what you need to paint. Think about the size, weight, and shape of your parts. If you work in mass car production or custom vehicle finishing, you need robotic painting machines with high speed and precision. For smaller jobs, spray painting robots with easy programming and extra accuracy will do the trick.

Check the table below to match robot features to your needs:

Criteria | Description |

|---|---|

Payload and Reach | Make sure your robot can handle your materials and reach every surface. |

Speed | Fast painting boosts efficiency in high-volume production. |

Easy programming | Simple controls save time and help you adjust quickly. |

Long term costs | Look for energy efficiency and low maintenance to keep your budget in check. |

Don’t just focus on the price tag. The total cost includes maintenance, energy, and upgrades. Many shops see a return on investment in 8 to 18 months when they choose the right paint shop robots. If you want seamless integration, pick automated machines that work with your current setup. AI-powered software helps you get better performance and precision, especially when you need high-speed mode or human-safe operation.

Top brands like ABB and Dürr lead in features and innovation. FANUC and Yaskawa offer great value for your budget. Kawasaki shines in heavy-duty jobs. Some new brands bring specialized solutions for unique needs.

Action Steps

Ready to choose your paint shop robots? Here’s what you should do:

Pick the right motion system. Articulated arms work best for most jobs. Cobots are perfect for tight spaces. SCARA robots fit special layouts.

Count every cost. The base price is only part of the story. Add up safety systems, sprayers, mounts, and vision tools.

Focus on tooling, not just the brand. Your finish depends on the applicator and material, not the logo.

Ask for demos. See the paint shop robots in action. Test for speed, precision, and efficiency.

Get quotes from different suppliers. Compare features, support, and total cost.

Check training and support. Proper training boosts performance and keeps your team safe. Ongoing support helps you solve problems fast.

Plan for the future. Choose paint shop robots with AI and features that let you grow.

Paint shop robots with AI, precision, and efficiency will help you win in mass car production or custom jobs. Take these steps, and you will find the best robotic painting machines for your budget and goals.

When you shop for a painting robot in 2025, focus on what matters most for quality. Start with the right motion system for quality results. Count the full cost, not just the robot, to protect your quality investment. Tooling shapes your quality finish more than the brand. Make sure integration and I/O options support your quality goals. Service and maintenance keep your quality high. Here’s a quick checklist for quality:

Pick the motion system that fits your quality needs.

Add up every cost for quality planning.

Match tooling to your quality finish.

Check integration for quality workflow.

Choose brands with real support for quality uptime.

Compare options, ask for demos, and talk to providers. You will find the best robot for your shop’s quality goals.