Robotic arms are making factory work different in 2025. AI, soft robotics, and edge computing help robots learn quickly. Robots can also change how they work fast. More than half of factories use robotic automation now. This helps them make better products.

|

Traditional Automation |

Intelligent Cobots |

|---|---|

|

Rigid, costly |

Flexible, safe |

These new robots are important. You get robots that are safer, smarter, and cost less.

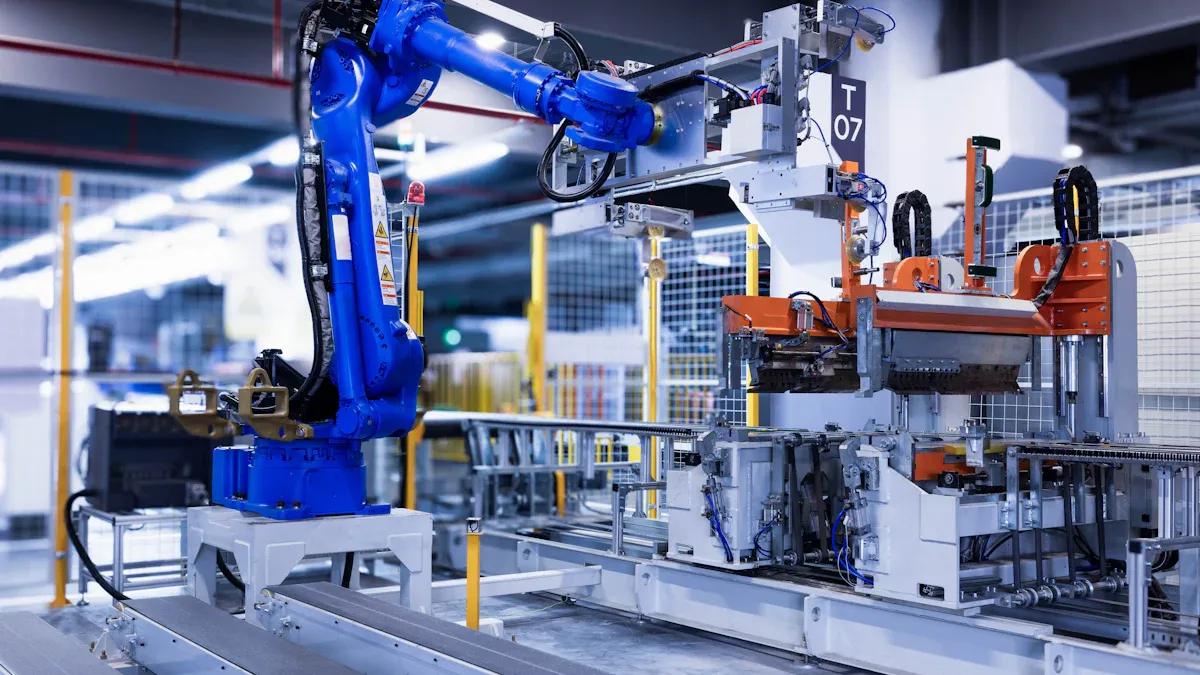

Robotic Arms: New Tech

Design & Components

Robotic arms look and move more like human arms now. The base can attach to floors, walls, or tracks. This makes the arm stable and strong. The joints can turn or slide like elbows or wrists. The arm can reach many places. The end effector is the tool at the tip. It can be a gripper, welding torch, or soft hand. Some end effectors have sensors. These sensors help the robot change its grip or movement.

Here’s how different industries use new robotic arms:

|

Industry |

Advancements |

|---|---|

|

Healthcare |

AI-driven robotic arms help doctors do surgery, give out medicine, and help people recover. |

|

Logistics |

AI-powered robotic arms sort and pack items, making orders faster and with fewer mistakes. |

|

Manufacturing |

AI helps robotic arms weld and put things together, even when parts are different. |

|

Agriculture |

AI-enabled robotic arms plant and pick crops, saving money and stopping food waste. |

Types in Manufacturing

Factories use different kinds of robotic arms. Each kind does a special job. Here is a simple guide:

|

Type of Robotic Arm |

Description |

|---|---|

|

Cartesian robots |

Move in straight lines with three sliding joints, good for precise work. |

|

Articulated robots |

Move like human arms with many joints, great for building, painting, and packing. |

|

Delta robots |

Have three light arms and work fast, perfect for picking and placing things quickly. |

|

Polar robots |

Use turning and sliding joints to reach in many directions, good for tasks that need lots of movement. |

|

SCARA robots |

Have two turning joints and one sliding joint, best for quick and accurate moves in electronics and food. |

People use these types for different reasons:

-

Articulated robots are flexible and move in many ways. They do hard jobs.

-

SCARA robots are fast and accurate, good for electronics and car parts.

-

Delta robots are best for quick pick-and-place work.

-

Collaborative robots, or cobots, work safely with people and help with jobs that need both humans and machines.

Core Technologies

Robotic automation uses new tech to make robots smarter. Actuators are motors that move the arm. Smart actuators make arms faster and more exact. Sensors help robots “see” and “feel” things. They can sense touch, pressure, and even taste. This helps robots do careful jobs.

Kinematics is the math for how arms move. Better kinematics lets robots reach tiny spots and move very accurately. In chip factories, robots put parts in place with tiny precision. In warehouses, robots pick and place things faster and make fewer mistakes.

|

Innovation Type |

Description |

|---|---|

|

Actuators |

Smart actuators make robots more exact and quick. |

|

Sensors |

Better sensors help robots adjust and interact right away. |

|

Collaborative Robots (Cobots) |

Cobots are changing how factories work. |

These technologies make robots easier to use and more reliable. Programming is simpler now, so more workers can learn to use robots.

2025 Trends

There are some big trends in robotics this year:

-

Artificial Intelligence (AI) and Machine Learning: Robots use AI to check data and know when they need fixing. This keeps factories working well.

-

Mobile Manipulators: Some robots can move around the factory, not just stay in one spot. They help move things and do different jobs.

-

Cobots: Collaborative robots work safely with people. They help with jobs that need both human thinking and machine power.

Other trends are:

-

AI lets robots check and learn while working.

-

Edge computing helps robots make choices fast by using data right where they work.

-

Soft robotics uses bendy materials, so robots can hold soft things like fruit or electronics.

-

Smart factories connect machines, sensors, and people all at once. This helps make every step better.

-

Flexible manufacturing means robots can switch jobs fast, so factories can change quickly.

Robots: Impact & Applications

Productivity & Safety

Factories are changing a lot because of robotics. Robots work much faster than people. They also make fewer mistakes. Robotic automation lets factories make more products. Production can go up by 10-15%. Costs can drop by as much as 20%. Robots use sensors and AI to change what they do right away. This means better quality and less waste.

|

Metric |

Improvement (%) |

|---|---|

|

Production capacity increase |

10-15% |

|

Cost reduction |

5-7% |

|

Reduction in production costs (AI robots) |

25% |

|

Quality increase (AI robots) |

|

|

Overall production cost reduction |

up to 20% |

Robotic automation makes factories safer for workers. Robots have sensors and vision systems to see people nearby. They slow down or stop if someone is close. Cobots have special safety features and force limiters. These keep people safe when working together. Software checks how robots work and can stop accidents before they happen.

Flexibility & Scalability

Robotics gives factories more ways to do different jobs. You can program robotic arms for many tasks. This helps factories switch between products fast. Robots work all day and night without stopping. This can make production 30% faster. Robots also make fewer mistakes, lowering errors by 25%. In food factories, robots boost productivity by 20-35%. They also help keep things clean and safe.

-

Robots work fast and never get tired.

-

They keep quality high and waste low.

-

Workers can do harder jobs while robots do the boring ones.

Robotic arms help factories change for new needs. You can change what robots do without buying new ones. This makes your business ready for new challenges.

Real-World Cases

Many companies use robotics to work better. Here are some examples:

|

Company |

Implementation Details |

Outcomes |

|---|---|---|

|

Tesla |

Used industrial robotics for welding, painting, and assembly in its Gigafactory. |

Increased efficiency, reduced defects, better quality, safer work. |

|

Amazon |

Used thousands of robots in fulfillment centers for picking, packing, and sorting. |

Faster order fulfillment and delivery. |

|

BMW |

Used robotic arms for welding, painting, and assembly, working with people. |

Better quality, shorter cycle times, smarter use of resources. |

Robots help in many jobs. You see them in assembly, welding, painting, picking and placing, material handling, and packaging. Industrial robotics also help with inspection and testing.

|

Industry/Application |

Specific Use Cases |

|---|---|

|

Assembly |

Robots put parts together quickly and accurately. |

|

Welding |

Robotic arms weld well and keep workers safe. |

|

Painting |

Robots paint evenly and save paint. |

|

Picking and Placing |

Robots sort and pack items fast. |

|

Material Handling |

Robots move things and lower labor costs. |

|

Packaging |

Robots pack products quickly and reduce waste. |

|

Others |

Robots check, test, and treat surfaces for special needs. |

Challenges

There are some problems when adding robotics to factories. Buying and setting up robots costs a lot. Small businesses may not have enough money for new robots. You need experts to program and fix robots. Training workers is important but takes time and money.

|

Setup Type |

Cost Range |

ROI Timeline |

|---|---|---|

|

CNC Tending |

$45,000 to $65,000 |

18 to 24 months |

|

Welding Cell |

$150,000 to $250,000 |

12 to 18 months |

|

Full Automation |

$500,000 to $1.2M |

24 to 36 months |

You must retrain workers or hire new robotics experts. Flexible training programs help workers learn new skills. Many programs give certificates in less than a year. Industry credentials and apprenticeships help workers get ready for new jobs. Work-based learning and support services help teams do well.

Using robotics can be hard. You need good software to avoid mistakes. Visualization tools show how robots move and work. You must plan for costs and teamwork with many groups. You also need to follow safety rules like ISO 10218-1 and ISO/TS 15066 to keep everyone safe.

Robotic automation helps you compete in your industry. You get faster production, lower labor costs, and better quality. Robots also make your supply chain stronger and more flexible. You must check your return on investment and make sure robots fit your needs.

You can see robotic arms making factories better. They help work become safer and faster. Robots also make jobs smarter. AI and mobile robots help factories change quickly. They make products better too. Cobots let people and machines work together. You do not have to fight with machines. Are you ready for these changes? You should think about using robots to help your team grow and change.

FAQ

What jobs can robotic arms do in a factory?

Robotic arms can weld, paint, pack, move items, and check products. You can use them for many tasks that need speed and accuracy.

Are robotic arms safe to work with?

Yes. You get safety sensors and smart controls. Cobots stop or slow down if you come close. This keeps you safe while working together.

How do you train to use robotic arms?

You can join short training programs or get certificates. Many companies offer hands-on classes. You learn to program, fix, and use robots in real factories.