You should pick a welding robot that fits your work amount, material, space, and money plan. Research shows that choosing the right robot features helps you work better. Welding automation lets you set up faster and make better welds. Welding robots 2025 give smart solutions for all business sizes.

Types of Welding Robots 2025

Main Robot Types

There are many welding robots 2025 you can buy. Each one is good for different jobs and materials. Here are the main types you should know:

-

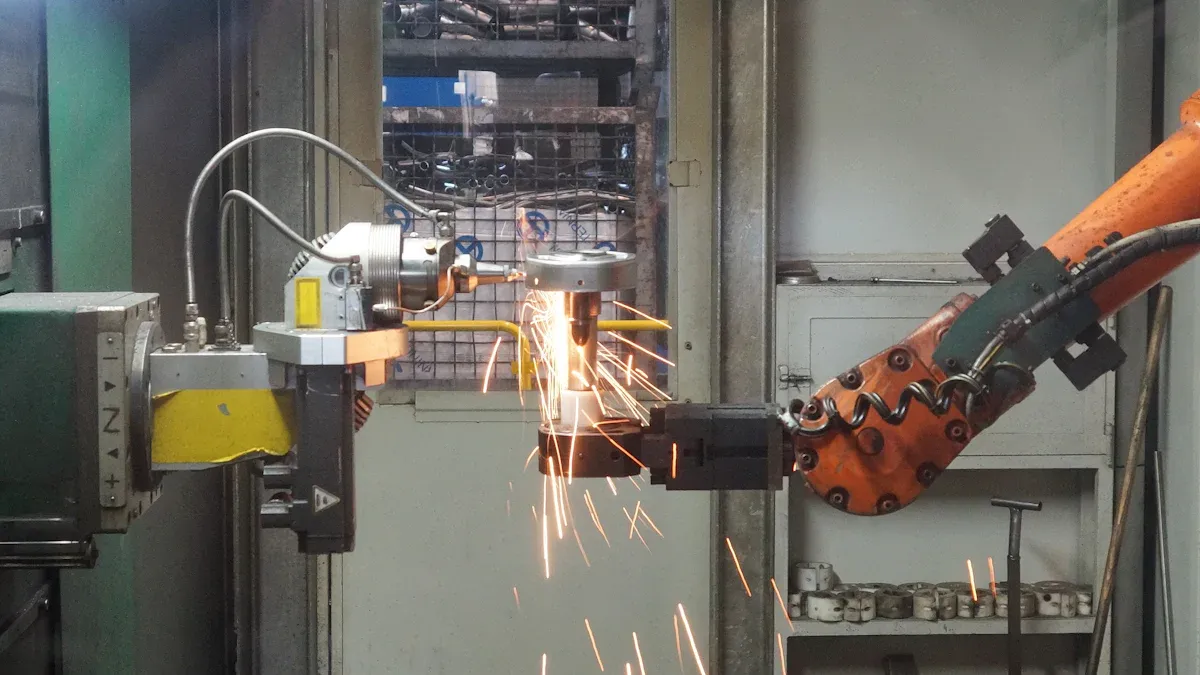

Arc welding robots melt metal to join pieces. They work well for carbon-steel frames and pressure vessels.

-

Spot welding robots join thin sheets at certain spots. These robots are used in car factories and busy lines.

-

Laser welding robots use strong light for fast, clean welds. They help make exact parts for planes and medical tools.

-

Plasma welding robots work with special alloys and tough plane parts.

-

Ultrasonic welding robots use shaking to join plastics. You will see them making medical gear.

-

Friction welding robots join rods and axles without melting metal.

-

Hybrid welding robots mix different welding ways for flexible jobs.

Matching Types to Needs

You need to pick the right welding robot for your material and job. Arc welding robots make strong, long welds. They are best for thick or mixed metals. Spot welding robots make strong points but do not seal edges. Use them for thin or medium sheet metals.

Laser welding robots keep welds clean and stop bending. These robots are good for planes and medical work. Plasma welding robots let you use special alloys. Ultrasonic welding robots are best for plastic parts in medical or electronics work. Friction welding robots join round parts like rods and axles.

Car makers use welding robots 2025 for car frames and bodies. Plane companies use them for fuselages and tight parts. Builders use these robots for steel frames and bridges.

Welding robots 2025 now have plug-and-play and better safety. Many connect to Industry 4.0 for live data and easy checks. Some robots use AI to check quality and save energy. These new features make welding robots safer and easier for your team.

Choosing a Robot Welder

Assessing Your Needs

Start by thinking about what you need to make. Think about what you will weld and how often you will do it. Here are some steps to help you pick the right robot welder:

-

Pick the welding type you need. MIG, TIG, plasma, and laser welding work best for different jobs.

-

Check how thick your material is. Thin sheets need a spot welding robot. Thick metals work better with an arc welding robot.

-

Look at the shape of your parts. Flat parts are easier for robots. Tubes or tricky shapes need special programming.

-

Count how many parts you weld each day. If you weld a lot, you need a robot that can keep up.

-

Decide how exact you need your welds. Some jobs need very tight measurements. Laser welding robots or plasma welding robots help with this.

-

Check what your parts are made of. Steel and aluminum work well with robots. Plastics need ultrasonic welding.

-

Look at how your parts fit together. Simple joints are easier for robots. Hard joints may need special tools.

-

Measure your workspace. Small spaces need short robot arms. Big spaces need longer arms.

-

Think about your workers’ skills. They need training to use a robot welder. Good training helps you get the most from your robot.

|

Factor |

Description |

|---|---|

|

Material Type and Thickness |

Steel and aluminum work well with robots. The thickness changes the settings you need. |

|

Weld Processes |

MIG welding is easy for robots. TIG and Stick welding need more skill. |

|

Joint Geometry and Accessibility |

Simple joints are best for robots. Hard shapes need special programming. |

|

Weld Quality and Inspection |

Robots make steady welds. You must check gas and part position to avoid mistakes. Check welds often to keep quality high. |

Cost Breakdown

You need to know the costs before you buy a robot welder. Entry-level collaborative robots cost $52,000 to $70,000 in 2025. These robots are good for small shops and people new to robots.

Industrial robot welding arms cost more. Full welding cell systems cost $150,000 to $250,000. These are best for big jobs and large factories.

|

Item |

Cost Range |

|---|---|

|

Entry-level cobots |

$52,000 to $70,000 |

|

Full welding cell system |

$150,000 to $250,000 |

You also need to plan for extra costs:

|

Cost Factor |

Description |

|---|---|

|

Maintenance Expenses |

You need regular care. Plan to spend 5% to 12% of the robot’s price each year. |

|

Programming Costs |

You pay for programming when you start and when you change parts. |

|

Safety Equipment |

You need mats, locks, and curtains for safety. Costs depend on your system’s risk level. |

-

For a $100,000 robot welder, plan to spend $5,000 to $12,000 each year for care.

-

Safety gear costs change based on your space and system.

Best Welding Robots Comparison

You want to find the best welding robot for your needs. Some models are good for beginners. Others are better for big jobs or very exact work.

|

Model |

Advantages |

Disadvantages |

|---|---|---|

|

Universal Robots |

Easy to use and set up |

Can’t lift heavy things |

|

FANUC |

Very fast and accurate |

Harder to program for new users |

|

AUBO |

Not expensive, easy to use |

Has fewer special features |

|

Doosan |

Works well |

Not as much support |

|

Han’s Robot |

Good price |

Needs extra software |

Universal Robots are easy to learn. You can use this robot welder quickly. FANUC is fast and accurate, but you need more training to use it. AUBO is good if you want to save money and is easy to use. Doosan works well, but you may not find as much help. Han’s Robot is a good price, but you need extra software.

If you need very exact welds for tricky parts, look for a robot welder with micron-level accuracy. Some robots use special motion control and laser sources for the best quality. These features help you make fewer mistakes and waste less.

|

Feature |

Description |

|---|---|

|

Welding Accuracy |

Micron-level accuracy means fewer mistakes and less fixing. |

|

Positioning and Motion Control |

Exact control gives better product quality. |

|

Advanced Features |

Laser source and wobble welding head help with hard jobs. |

Robotic automation helps you work faster and make better products. The best welding robots for 2025 have smart features, easy programming, and strong safety. You can find a robot welder for any job, from small shops to big factories.

Picking the best welding robot means you need to match its features to your work, space, and money. Look at this table to help you choose:

|

Factor |

Why It Matters |

|---|---|

|

Planning |

Gets you ready for using robots |

|

Plant Space |

Makes sure the robot can move easily |

|

Staff Skills |

Helps with robot setup and care |

|

Expense |

Makes sure your money is well spent |

|

Welding Type |

Finds the right robot for your jobs |

To pick the right robot:

-

Know what kind of welding you do and how much room you have.

-

Check prices and see what kinds of robots are out there.

-

Talk to sellers to get good advice.

-

Ask to try the robot or see a demo before you buy.