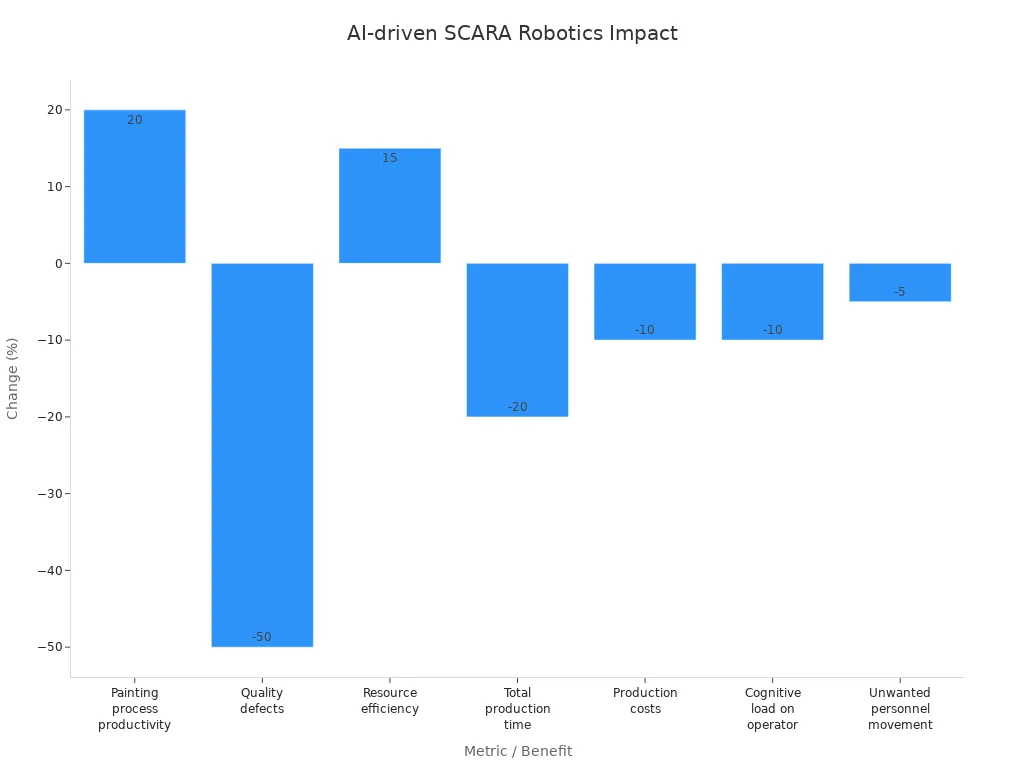

You see AI-driven teamwork is changing how SCARA robots work in 2025. Factories now have 20% more painting done. There are 50% fewer quality mistakes. Workers feel less stress. Companies save 10% on costs. Look at the table below for more big changes:

|

Metric / Benefit |

Improvement / Impact |

|---|---|

|

Painting process productivity |

+20% |

|

Quality defects |

-50% |

|

Resource efficiency |

+15% |

|

Total production time |

-20% |

|

Production costs |

-10% |

|

Cognitive load on operator |

-10% |

|

Unwanted personnel movement |

-5% |

You see more factories use these robots now. This is because of new technology, help from the government, and the need to work faster and better. But there are problems too, like high costs and changes in jobs. Think about how these changes could affect your own work.

SCARA Robots Overview

Key Features

SCARA robots are special because of how they are built. Their arms move fast from side to side. They also stay strong when moving up and down. This helps them do jobs quickly and with care. The four-axis setup lets the arm move easily on a flat surface. It also keeps the robot steady when going up or down. SCARA robots are good for short jobs that need to be done over and over. They help keep work steady and smooth. Here is a table that shows what makes SCARA robots different:

|

Characteristic |

Description |

|---|---|

|

Type |

Selective Compliance Assembly Robot Arm (SCARA) |

|

Arm Design |

Quick, accurate side-to-side movement |

|

Joints |

Two rotary joints for flat area movement |

|

Axes |

Four servo axes for precision |

|

Payload Capacity |

3–800 kg |

|

Reach |

Up to 3100 mm |

|

Speed |

Up to 2 m/s |

|

Repeatability |

±0.025 mm |

|

Applications |

Assembly, packaging, pick-and-place |

|

Limitations |

Limited reach, not for heavy lifting |

|

Trends |

AI, modular designs, better safety |

Main Applications

SCARA robots are used in many types of work. In car factories, they help put parts together. In electronics, they move small pieces or work with circuit boards. Food companies use them to pack and process food. Here are some jobs they do:

-

Fill trays with food

-

Pack food into boxes

-

Place parts on circuit boards

-

Tighten screws in many places

-

Put labels on products

SCARA robots can also help in medicine labs and with clean packaging.

Choosing a SCARA Robot

You need to think about a few things before picking a SCARA robot. Check how much weight it can lift and how far it can reach. See how exact and steady it is. Plan for training and fixing the robot. Work with people who know a lot about SCARA robots. Think about how much it will cost over time, not just the first price. Here is a table to help you choose:

|

Criteria |

Description |

|---|---|

|

Performance |

Payload, reach, accuracy, repeatability |

|

Technical Evaluation |

Compare models, total cost, support |

|

Implementation Planning |

Integration, training, maintenance |

|

Integrators |

Experience and skill level |

|

Flexibility |

Ability to adapt and operator training |

AI and Collaboration

AI Technologies

New AI tools change how you use scara robots. AI software helps robots learn from each job. This software lets robots find mistakes and fix them fast. You can trust robots to do many jobs with great care and speed. Machine learning helps robots understand what you do. Robots can change how they work to match your actions. Scara robots can work with you, not just for you.

-

Robots now:

-

Know what you do better.

-

Learn new jobs and fix errors.

-

Work with you for better teamwork.

-

|

Evidence |

Description |

|---|---|

|

Integration of Collaborative Robots |

Collaborative robots help you make choices and do repeated work. |

|

Intuitive Communication |

You can use gestures, voice, or eyes to guide the robot. |

|

Enhanced Productivity |

You and the robot finish jobs faster and safer together. |

Human-Robot Teamwork

Scara robots work next to people in many places. In electronics, robots help build tiny parts and make fewer mistakes. In car factories, robots handle parts with care and work faster. Food companies use robots to keep food clean and safe. Robots do hard work so you can make big decisions.

|

Industry |

Collaborative Tasks |

Benefits |

|---|---|---|

|

Electronics |

Tiny part building, quick work |

More work done, fewer mistakes |

|

Automotive |

Careful part handling |

Better accuracy, faster work |

|

Pharmaceutical |

Clean automation, steady accuracy |

Meets health rules, stays reliable |

|

Food Industry |

Automated food work |

Cleaner food, same quality every time |

Vision and Adaptability

AI gives scara robots better sight and flexibility. Robots now see and handle many things. They use live data to make smart choices. You can count on them for careful jobs. AI helps robots find problems and keep products good. Robots know when they need fixing, so you save time and money.

|

Advancement Type |

Description |

|---|---|

|

Enhanced Sensory Capabilities |

AI vision helps robots see and handle different things. |

|

Adaptive Decision-Making |

Robots use live data to work better in new places. |

|

Predictive Maintenance |

Robots warn you before something breaks. |

|

Process Optimization |

AI looks at work data and finds ways to go faster. |

|

Improved Quality Control |

Vision systems find problems early for better products. |

Scara robots with AI make your factory smarter and more flexible. They bring speed, care, and teamwork to every job.

SCARA Robots in Manufacturing

Productivity Gains

You can see big changes in your factory when you use scara robots. These robots help you finish jobs faster and with fewer mistakes. Many companies report that production line efficiency can increase by 40% or more after adding scara robots. You can watch cycle times drop to as low as 0.3 seconds for simple pick-and-place tasks. This means you get more products made in less time. Labor costs can also go down by up to $80,000 per operator each year.

Scara robots give you high speed and accuracy. You can trust them to do the same job over and over with high precision. Many manufacturers now use scara robots to improve quality. In fact, 53% of companies say they use robots to make their products better. More companies now focus on robotics to boost quality, with 40% making it a top goal. You can see how scara robots help you reach your targets for both speed and quality.

Safety and Workforce

You want your workplace to be safe and your team to feel confident. Scara robots help you reach these goals. They use real-time monitoring to spot problems before they become serious. This keeps your workers safe and your machines running smoothly. You do not need to worry about sudden breakdowns because scara robots use predictive maintenance. They tell you when something needs fixing, so you avoid long stops.

Scara robots can work right next to people. You do not need safety fences. This makes your workspace more open and flexible. Smart sensors in scara robots watch every move and adjust right away if something changes. You get more reliability and safety every day.

Here is a table that shows how scara robots make your workplace safer and more efficient:

|

Feature |

How It Helps You |

|---|---|

|

Real-time monitoring |

Finds safety issues before they grow |

|

Predictive maintenance |

Reduces downtime and keeps work flowing |

|

Collaborative work |

Lets robots and people work side by side safely |

|

Smart sensors |

Adjusts instantly for better safety and reliability |

You can see that scara robots do more than just work fast. They help you protect your team and keep your factory running well.

Case Studies

Let’s look at some real examples from 2025. In a large electronics plant, you can see scara robots working with people to build circuit boards. The company reports a 40% jump in production speed and a big drop in mistakes. Workers say they feel less tired because the robots handle the hard, repetitive jobs.

In a car parts factory, scara robots use ai-powered software to check every part for quality. The robots spot tiny errors that people might miss. This leads to fewer returns and happier customers. The company also saves money because the robots need less downtime for repairs.

A food packaging company uses scara robots to pack products quickly and safely. The robots’ high precision means every box looks the same. The company meets strict safety rules and keeps food fresh. Workers spend more time checking quality and less time doing heavy lifting.

You can see how scara robots change the way you work. They bring speed, precision, and safety to your factory. You get better results and a stronger team. If you want to stay ahead, you should think about how scara robots can fit into your own operations.

Challenges Ahead

Integration Issues

Adding scara robots with AI to your factory can be tough. New technology costs a lot, which is hard for small companies. AI needs good data, but sometimes your data is old or not good. Old machines may not work with new robots. This makes it harder to connect everything. You also need people who know how to set up and use these systems. Many factories do not have enough trained workers.

|

Challenge |

Description |

|---|---|

|

High cost of AI implementation |

Initial investments can be significant, especially for small and medium enterprises (SMEs). |

|

Data quality |

The effectiveness of AI relies heavily on the quality of data, which may be outdated or unreliable. |

|

Legacy Systems |

Integrating old equipment with new technologies complicates AI implementation due to compatibility issues. |

|

Lack of experienced specialists |

There is a shortage of qualified personnel to manage AI integration, necessitating training or hiring. |

You can use smart ways to fix these problems: 1. Try AI with scara robots in one part of your factory first. 2. Work with other companies to share ideas and learn from them. 3. Train your team often so they get better at new skills. 4. Give customers simple tools to help them pick and fix robots.

Workforce Training

Your team needs to get ready to work with scara robots. Training helps everyone feel safe and ready. Workers must learn how to use robot arms with rotary joints. They need to watch and work with machines. They should know how to read sensor data for better safety. Change can be hard, so use programs that help people accept new ways. Getting certified in robotics helps build trust and teamwork.

-

Learn to use scara robot arms with rotary joints.

-

Train to watch and work with robots.

-

Know how to read sensor data for better work.

-

Use programs to help your team with changes.

-

Get certified in robotics for safety and teamwork.

Ethics and Operations

You need to think about ethics when using scara robots. Sometimes, AI can be unfair and cause problems. You must make sure your robot systems are clear and easy to check. If something goes wrong, you should know who is responsible. Some jobs may change or go away, so help workers learn new skills. AI can also spread wrong information, so check your systems often.

-

AI in scara robots can sometimes be unfair.

-

You need clear rules for every robot decision.

-

Some jobs may change, so retraining is important.

-

AI can spread wrong information, so check your robots often.

Future Steps

Adopting AI-Driven SCARA Robot Solutions

First, think about what your factory needs. SCARA robots are used in electronics, medicine, plastic molding, and food packaging. Check how much weight the robot can lift. See how far it can reach and where it can work. Cycle time and precision are important for putting things together. Make sure the end-effector matches your products. Integration support helps you set up robots quickly. Many companies use scara robots to fix worker shortages and keep quality high. You can make more products and stay ahead with automation.

Key Takeaways

-

SCARA robots work in many industries and do fast jobs.

-

Focus on accuracy, repeatability, and help with setup.

-

Buying scara robots helps you when you need more workers.

-

You can keep your products good and make more of them.

-

SCARA robots help your business compete with others.

|

Factor |

Why It Matters |

|---|---|

|

Payload Capacity |

Lifts different weights |

|

Reach & Work Envelope |

Works in your space |

|

Cycle Time |

Makes assembly faster |

|

Precision |

Keeps product quality the same |

|

Makes setup and training simple |

Looking Forward

You will see more teamwork between scara robots and people. Better vision systems will help robots find and track items for hard jobs. AI-powered software lets robots learn and change by themselves. Digital Twins make virtual places for testing and training. Real-time coaching helps your team and robots work better together. You will get safer workspaces and smarter robot solutions. SCARA robots will keep changing how you do assembly, speed, and quality in your factory.

You can see how teamwork with AI changes SCARA robotics in 2025. Robots work next to you and keep everyone safe. They use special vision to see very small details. Robots can also learn new jobs quickly.

|

Feature |

Description |

|---|---|

|

Safety-Certified |

Robots have sensors that help them work safely with you. |

|

Unmatched Precision |

AI vision lets robots see tiny things very clearly. |

|

Enhanced Adaptability |

Robots can move gentle parts without breaking them. |

You get more work done and stay safer, but jobs may change. You also need to think about what is right and fair. Watch for new ideas and try new ways to use these robots at work.