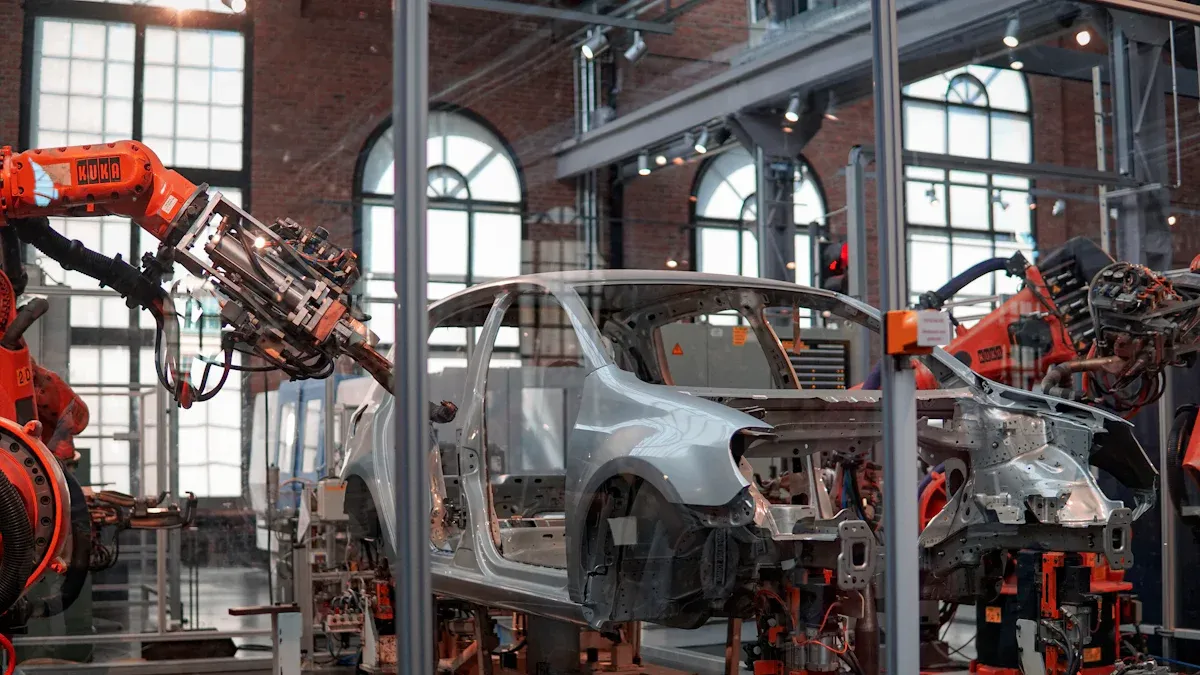

You see industrial robots for welding give very good accuracy and steady results. These systems use smart sensors and controls to help them be exact and make fewer mistakes. Car makers need this accuracy to follow tough rules. As more people want these products, you get better quality and faster work from robotic welding.

Welding Accuracy with Industrial Robots

Robotic Welding Consistency

You need every weld to look the same and meet rules. Industrial robots for welding help you do this. These machines follow set paths with great accuracy. They do not get tired or lose focus. This means you get the same good weld each time.

Robotic welding uses new technology to keep welds accurate. Here is a table that lists some main technologies and what they do:

|

Technology |

Benefits |

Application Areas |

|---|---|---|

|

MIG Welding |

Fast and efficient, good for thick materials |

General manufacturing |

|

TIG Welding |

Very precise, best for thin materials and detailed work |

Aerospace and automotive |

|

Laser Welding |

Super precise, less heat damage, good for tricky shapes |

High-tech industries and special uses |

|

Industrial Robots |

Same weld quality, fewer mistakes, faster work cycles |

Many areas like furniture and electronics |

|

Collaborative Robots |

More precision in special jobs, people and robots work together |

Aerospace and tough part welding |

Robotic welding works for many types of welding jobs. Automated welding gives you the same weld every time by repeating steps. Robots do not slip or make mistakes like people. This means less waste and more accurate welds.

Robotic welding systems save job settings in their memory. Each weld part matches the right job, so the robot uses the correct settings. This keeps welds accurate from start to finish.

You also get safety benefits. Robots do dangerous jobs, so people are safer. Robots are good for jobs that repeat a lot. They keep their set accuracy and give the same weld every time. This means less fixing and saves materials.

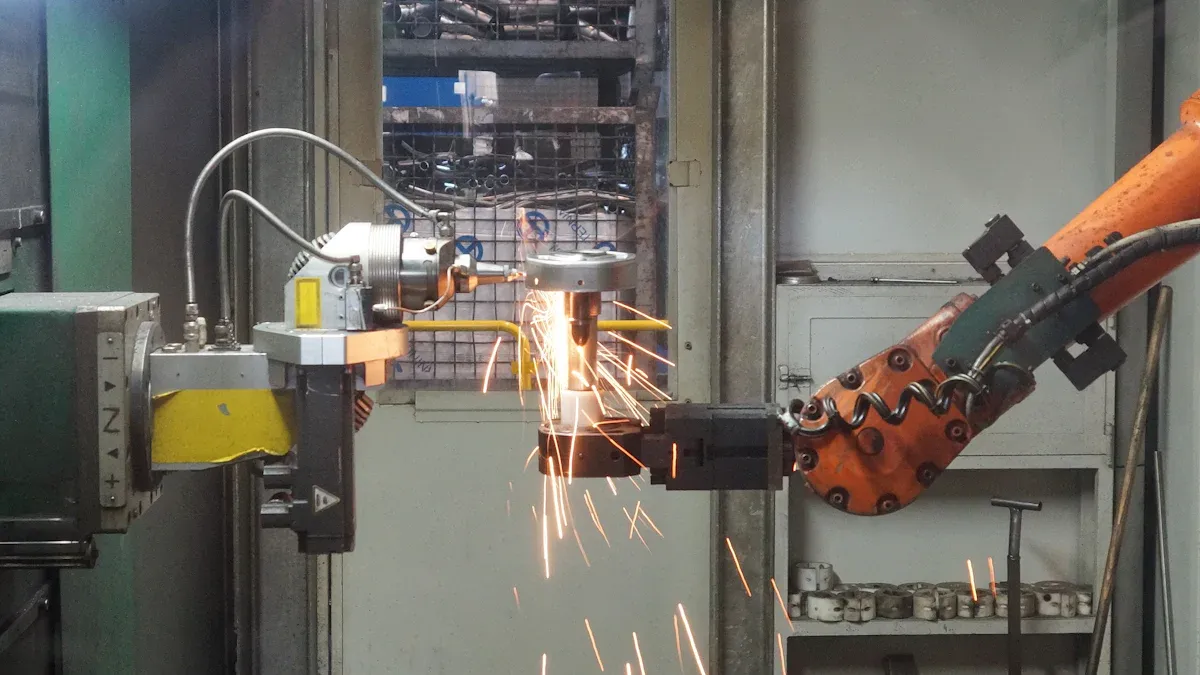

Eliminating Weld Defects

Manual welding can cause problems like burn through, lack of fusion, undercut, and slag entrapment. These happen because people get tired or make mistakes. Robotic welding lowers these problems by controlling heat and arc time very well.

Here is a table that shows common weld problems and how robots help fix them:

|

Defect |

Cause |

Solution |

|---|---|---|

|

Incomplete Penetration |

Not enough heat, wrong settings, or bad joint design |

Change welding current, voltage, and speed. Make sure joints fit and line up. |

|

Surface Porosity |

Dirty metal, not enough shielding gas, or too much moisture |

Clean metal before welding. Use good gas and check gas flow. |

|

Lack of Fusion |

Wrong settings, bad joint prep, or gun not lined up |

Check and set welding settings for the material. Prepare joints and line up the gun. |

|

Weld Spatter |

Too much current, wrong polarity, or bad gas mix |

Change current and voltage for the material. Use right polarity and gas mix. |

|

Crater Formation |

Stopping the arc too fast without filling the crater |

Use machines that fill craters. Lower current slowly at the end. |

|

Weld Bead Profile Irregularities |

Wrong speed, uneven heat, or bad gun position |

Change speed and heat. Use robots for better control. |

|

Arc Blow |

Magnetic fields mess with the arc, bad grounding |

Improve grounding and connections. Use anti-stick welding parts. |

Robotic welding gives you more repeatable and tighter welds. This means fewer mistakes. New robotic systems can even change as they work to make welds better. They use sensors to watch voltage, current, and heat. If something is wrong, the system can fix it fast. This stops problems before they start.

Vision sensors help robots find the right place to weld. They give feedback so the robot can change its path or settings. This keeps welds accurate and high quality. Robots with AI can also change how they weld if they see a new joint or thickness. This helps avoid problems like undercut or weak welds.

You can trust top brands for good robotic welding. Companies like FANUC, Yaskawa Electric Corporation, and Automation International, Inc. are well known. They make systems that give high accuracy and quality for many jobs.

Robotic welding has changed a lot in ten years. Now, you have tools that check welds and find problems right away. Robots can work with other machines to keep things moving and lower mistakes. New cobots help you set welding steps, even if you are new to robots.

When you use industrial robots for welding, you get accurate, precise, and steady welds. You also have fewer mistakes and better safety. This makes robotic welding a smart choice for any business that wants good welds and reliable results.

Integration and Quality Comparison

Planning and Training

You need to plan and train well to use industrial robots for welding. Good planning helps you make your workspace safe and efficient. You must know about welding and robotics before you begin. If you follow the right steps, you can get high weld accuracy and precision.

Here are the main steps to follow when you plan and program robotic welding systems:

-

Learn the basics of welding and robotics first.

-

Get training from the robot makers.

-

Make your workspace safe and efficient.

-

Calibrate your equipment for accurate welding.

-

Start with easy programs to see what the robot does.

-

Test your programs and improve them with real results.

-

Write down your steps to keep things the same and fix problems.

Operator training is very important in robotic welding. When you train operators, they work safer and better. Trained operators can program robots more accurately. They fix problems faster and keep the robots working well. Skilled operators make better welds and help you get the most from automation.

You may have some problems when you add robotic welding to your factory. The equipment and training cost a lot at first. Setting up and programming robots is hard and needs special skills. It can be tough to find workers who know robots. Some robots do not work well for small jobs. You need to plan for these problems before you start.

|

Challenge |

Description |

|---|---|

|

High initial investment |

You need to spend a lot at first for equipment and training. |

|

Complex setup and programming |

You need special skills to set up and program the robots. |

|

Skilled labor shortages |

It can be hard to find people who know how to work with robots. |

|

Limited flexibility |

Some robots do not work well for small or custom jobs. |

If you plan well and train your team, you can solve these problems. You will get better weld accuracy, higher precision, and more reliable results.

Robotic Welding vs Manual Welding

You might wonder how robotic welding is different from manual welding. Robotic welding gives you better weld quality, more accuracy, and higher consistency. Manual welding depends on the welder’s skill, so results can change from person to person.

Here is a table that shows the main differences:

|

Aspect |

Robotic Welding |

Manual Welding |

|---|---|---|

|

Weld Quality |

Enhanced weld quality with minimal defects |

Variable quality, depends on the welder’s skill |

|

Consistency |

High repeatability and consistency |

Inconsistent results due to human factors |

|

Scrap Production |

Reduced scrap due to accuracy |

Higher scrap rates due to variability |

|

Suitability for Projects |

Not suitable for smaller projects |

More adaptable for small, complex tasks |

Robotic welding systems give you steady quality and fewer mistakes. You do not have to worry about workers getting tired or making errors after long hours. This means you spend less time fixing mistakes and more time making good products. Automated welding also saves money because one skilled worker can watch several robots at once.

Many companies have seen big improvements after switching to robotic welding. Caterpillar Inc. lowered scrap rates by 15% and made better products. Vortex Companies made more products and more money by using cobot welders. Advanta Southeast LLC made 400% more products after adding robotic welding. General Motors found that robotic welding can cut labor costs by half and raise productivity by 30%. You can also see 25% fewer defects compared to manual welding.

|

Benefit |

Description |

|---|---|

|

Increased Throughput |

Robots can make three to five times more parts in the same time. |

|

Reduced Labor Costs |

One skilled worker can manage several robots, so you need fewer workers. |

Robotic welding also makes your workplace safer. Robots do the dangerous jobs, so your team stays safe. You get more reliable results because robots do not get tired or lose focus.

Some people think robotic welding costs too much or is too hard to use. Today, collaborative robots cost less and are easier to program. You do not need a big space, and you can use robots for both big and small jobs. Robots help skilled welders by doing the boring work, so your team can focus on harder tasks.

You need to keep your robotic welding systems in good shape. Regular checks and maintenance help you avoid downtime and keep weld quality high. Clean the cooling system, check gas lines, and make sure all parts work well to get the best results.

Many companies use advanced tools to check weld quality. Systems like ARC-SCAN™ and i-FACT MICRO™ measure welds and find problems right away. You can also use laser, X-ray, and ultrasonic tests to make sure your welds meet high standards.

Real-world examples show how robotic welding helps companies reach high standards. Kawasaki Motors Manufacturing Corp. automated 80% of their welding and improved both productivity and quality. Last Arrow Manufacturing used FANUC cobots to boost flexibility and profits while letting skilled welders focus on harder jobs.

When you use industrial robots for welding, you get better weld accuracy, higher precision, and more reliable results. Robotic welding helps you make more products, save money, and keep your team safe. You can trust robotic automation to help you meet the highest welding standards.

You get high welding standards with industrial robots by using new technology and good control. Skilled teams help too. Robots make welds that are exact and steady. Companies make more money, have fewer mistakes, and get better products.

-

More people are using robotic welding now.

-

Robots give the same results and make less waste.

|

Aspect |

Benefit |

|---|---|

|

Productivity |

Welds are faster and more reliable |

|

Weld Quality |

Fewer mistakes and better accuracy |

|

Labor Costs |

Costs go down and there is less waiting |

FAQ

What types of welding can industrial robots perform?

You can use robots for MIG, TIG, spot, and laser welding. These robots work well for many materials and different shapes.

Do you need special training to use robotic welding systems?

You need training to program and maintain robots. Training helps you get better welds and solve problems faster.