The parts of a robot all play a role in its operations and determine the kind of tasks it can be used for. Therefore, having an in-depth understanding of such parts would be the first step towards choosing the right industrial robot for your needs. While there are many parts to consider, perhaps it would be beneficial to start with one of the key ones; a robotic manipulator.

Table of Contents

What is Robotic Manipulation?

A robot is a machine that is programmed to automatically perform specific tasks predictably. To do this, it has to handle objects and either move them or impact them through actions like welding or drilling. It is this handling or procedures performed on objects that is referred to as robotic manipulation. This definition thereby gives us context to define robotic manipulators.

A robotic manipulator is an arm-like structure joined to the body of a robot and is used to execute tasks. A robot without a manipulator would be the equivalent of a person performing a task with their hands tied behind their back, it simply is not viable. It is, in fact, for this reason that robotic manipulators are also known as robot arms.

What do Robot Manipulators Consist of?

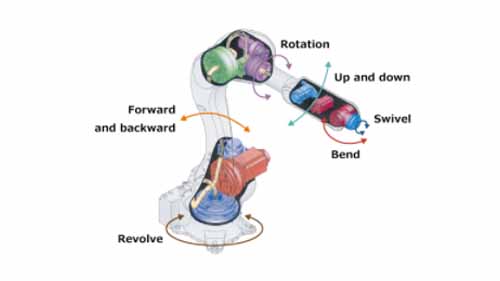

Source: Kawasaki

Robot manipulators consist of a series of joints and links fused in their interior structure. From the outside, the robotic manipulator arm only seems to be mounted onto the robot. However, the series of joints and links go further into the robot body to bind them. This ensures that the robot and the manipulator work together in coordinated fluid motions.

Links are rigid components that merge different parts of a robot. While their rigidity provides a firm structure, it would make it difficult for the robot parts to move during tasks. As a result, joints are added to the links to facilitate flexibility. Joints are movable components that slide against each other to facilitate linear, rotary, or revolutionary motion of robot parts. They are built and work in the same way as a human elbow or knee.

Robot Manipulators in Different Robots

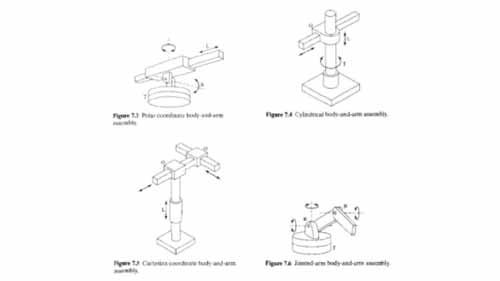

Source: www.brainkart.com

The types and number of joints that a robot manipulator has determines its degrees of freedom, the shape of its work envelope, and how it can be applied. This in turn determines how a robot is categorized. For illustration, let us examine different types of robots and the structures of their robotic manipulators.

Cartesian Robot- its manipulators are linked using 3 prismatic joints which are perpendicular to each other and only provide linear sliding motions. As a result, a Cartesian robot is classified as a 3-axis robot and has a geometrical work envelope.

Polar Robot- the arm and body of a polar robot are joined using a revolute joint. This type of joint enables circular motions which enable the polar robot arm to move within 3 axes in a polar geometry system.

Cylindrical robot- a cylindrical robot arm operates using a rotary joint at the base and a linear joint that allows it to move along the vertical axis. The setup of these joints allows for the manipulator to elongate and retract but its work envelope is still rather limited to a small cylindrical shape.

SCARA Robot – the joints in a SCARA robot are rotary and facilitate its movements along the XY axes while remaining rigid in the Z-axis. Due to the joints being a horizontal plane, SCARA robots have wide work envelopes in a semi-circular shape.

Articulated Robot– an articulated robot has the most flexible manipulators among all other robots. The robotic manipulator arm is linked to the robot body by a rotary joint while the elbow and other parts in the arm are linked using revolute joints. The revolute joints allow the arm to roll, pitch, and yaw thereby making a 6-axis robot.

Applications of Robotic Manipulators

The flexibility of various robotic manipulators can be harnessed to automate processes in different industries. Examples of such application include:

Robotic surgery- in this application, an articulated robotic manipulator is fitted with surgical instruments as end-effectors. It is controlled remotely by a surgeon to execute surgical maneuvers.

Pick and place – this is a common industrial application where robot manipulators are applied for repetitive pick and place tasks such as packing goods.

PCB Assembly – in this instance, a robotic manipulator replaces the hands of a human worker to assemble microparts on a PCB board with high precision and speed.

Conclusion

It is safe to say that the robotic manipulator meaning in robotics goes further than just the function. It goes further to define the structure and how a robot can be applied. Quality manipulators from a reputable robotic arm manufacturer would therefore be a worthy investment for anyone venturing into robotics.