Robotic arms are designed in varying ways, depending on the task they are meant to handle. Some are so big that they can flip an entire car in the air like a ball, and some small enough to thread the eye of a needle. These variations in sizes are what make robotic arms the most reliable machines in the manufacturing space.

We will be looking at giant robot arms, the characteristics, the robotic arm project roles they are designed for, and all the features that make them function as intended. If you have been having questions about giant robotic arms or planning to buy a robotic arm, then this is the article for you.

Table of Contents

The Characteristics of a Giant Robot Arm

Every robotic arm is designed in an almost similar fashion since they all exhibit similar movements when they are operational. The following are some of the general characteristics that you would find in a giant robot.

Controllers

Source: Pinterest

A robotic controller is a vital part of the robotic arm because it is what is used to determine how the entire robotic arm moves around. Controllers usually come in small boxes that are hard programmed with robotic software, and that is all an operator needs to control a giant robotic arm no matter how big it may be. There’s the option to program them automatically where the giant robot arms move on their own and also the option of leaving most of the control in the hands of a human operator. For the more advanced robotic arms, the controllers come in the form of an entire computer system that runs autonomously with some simple joysticks for manual functions when the need arises.

Arms

Robotic arms are the parts that handle the crux of the job. A simple robotic arm has three components; the shoulder, the elbow, and the wrist. These are joints that move independently, supporting each other where movement is involved. The arm can move in any direction depending on the type of giant robotic arm in question. The wrist is the most important part of the entire arm, and it has to be flexible enough to accommodate the end effector.

End Effector

Source: Pinterest

This is the part that holds the product directly. It usually comes with at least two claws which are used for holding. Most end effectors can spin a total of 360 degrees, and this is what makes them super fast when it comes to handling heavy items. The end effectors of giant robot arms need to be extra strong to avoid breaking off.

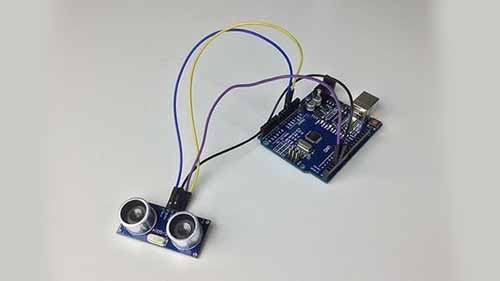

Sensors

Source: Pinterest

Giant robot arms are advanced robotic technology, and what makes them this good is the presence of sensors. These robotic sensors work alongside the program to give the giant robot arm the ability to be self-aware of everything around them. This stops them from bumping into each other or colliding with other objects. This is what also makes these giant robots safer as collaborative machines as they can work alongside human beings.

How to Choose a Heavy-Duty Robot Arm

The reason anyone would go for a heavy-duty large robotic arm would be the need to handle huge payloads. For this reason, the selection process has to be very thorough. The following are some of the thighs you need to consider when choosing a heavy-duty arm.

The Payload

The payload is the maximum amount of weight that a robotic arm can handle without breaking apart. Giant robotic arms are designed for heavy tasks like palletizing, which require the accurate lifting of heavy products and arranging them in a neat pile. You also have to factor in the weight of the robot arm into your calculations to get a clear picture of what needs to be adjusted when operations begin.

The Number of Axes

The more the axes, the more flexible and more stable the robotic arm. If a simple task of picking and placing is what you are going for, then you can go for a simple 4-axis robotic arm. However, if what you want is multitasking, then you would be best served with something that has more than six axles. Be aware, however, that the more the ales, the more sophisticated the software needed to run it.

Reach Range

Knowing the maximum range a factory robot arm can reach will save you a lot of pain. When versatility is what you are looking for, then getting a robotic arm with the longest arm reach would serve you very well as that will enable the robot to handle a number of tasks at the same time. The maximum vertical reach of a giant robotic arm is determined by measuring the distance starting from the lowest point the robot can reach to the maximum height that the end effector tip can reach. The longer they reach, the costlier the robot because that will require the base of the robot to be wider to support the entire weight.

Repeatability

Repeatability is the biggest reason why manufacturers are turning to robotic automation systems in the first place; the manufacturing process involves doing the same things over and over again because the products in an assembly line are supposed to be identical. A giant robot arm must be able to repeat these tasks with the highest accuracy possible. The margins of errors are supposed to be as minimal as possible, but considering how advanced robots are getting these days, this is nothing to worry about anymore.

The Speed

Speed is everything, and no matter how big a robot arm may be, it still has to get the job done faster than human workers. Some tasks require higher speeds compared to others, but the bottom line is that you have to know the maximum speed that your giant robot can post so that you can know the options available to you in the future when you need to repurpose the giant robotic arm for another task when the need for it arises.

The Advantages of Big Robot Arm for Project

So why would you go for a giant industrial robot arm? What are the benefits they bring to the production compared to the use of regular ones? The following are some advantages of using giant robot arms on your manufacturing floor.

They increase efficiency and precision, which increases the quality of production and cuts down the cycle times that were very common before automation became a thing.

They are super fast and can carry out tasks faster and for longer periods without stopping. Some can even work non-stop for a week with little to no supervision.

They have improved the working conditions by cutting down on work-related accidents that were very common when human workers were left to handle heavy machinery.

Conclusion

The use of industrial robots is not going to go down any time soon; the opposite is what’s happening worldwide. This may spell doom for the labor force, but there’s no helping it since robots are way more efficient and cheaper in the long run. If automating your business has been in the cards for long, but you are unsure of which steps to take, then don’t hesitate getting in touch with us, the best industrial automation manufacturers, when you can and have all your questions answered by a qualified team of experts.