Modern robots are renowned for being faster, more compact, and affordable than early-model robots. Robots are now widely used in all kinds of industries, such as robotic aluminum welding for automobiles, heavy machinery, railway locomotives, door frames, and others. This is largely attributed to technological advancements and new innovative robot designs. However, while such attributions are true, one aspect of progress in robotics often goes unmentioned: robot parts.

Industrial robots are made up of a series of parts that work together to fulfill various tasks. As technology has evolved, they too have been improved and resulted in higher-performing robots. Yet, the mystery remains, what are the parts of a robot and how do they actually work? Here is a quick and easy guide to robot parts.

Table of Contents

What are Robotic Parts?

Source: Pixabay

Robotic parts are a blend of metallic and electronic components fused to form the structure of a robot. Each part plays either a structural role, like insulating electrical components, or a functional role like powering the robot. While robot manufacturers may use parts differently based on their robot design, the overall concept and the functions of such parts is often similar.

What are the 5 Main Components of a Robot?

Given the high level of automation involved, robot structures are quite complex. It may be impossible to define every nut, bolt, and circuit in a robot. There are, however, 5 main components that are fundamental to an industrial robot and thus worth highlighting.

Robotic arm

End-effector

Motors

Controller

Robot sensors

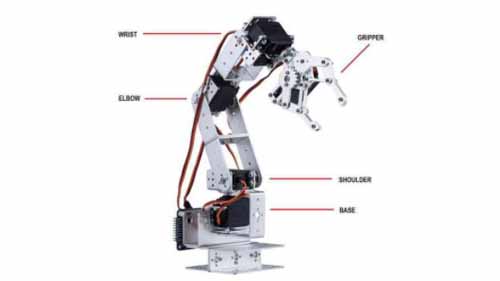

Robotic Arm

Source: link.springer.com

A robotic arm is also known as a manipulator. It is the part of an industrial robot that is used to execute tasks. Its structure is akin to that of the human arm and consists of a shoulder, an elbow, and a wrist. The shoulder is the part of the robotic arm linked to the mainframe of the industrial robot. The elbow is the jointed part of the arm that flexes as it moves and the wrist is the end of the arm that performs the actual task.

For flexibility, a robotic arm is fitted with various joints that allow it to move in different directions when working. A 6-axis robotic arm, for example, has more joints than a 4-axis arm which is less flexible. Additionally, the structures of robotic arms vary in terms of how far they can reach and the payloads they can handle.

Nowadays, the robotic arm has been maturely developed, a lot of robotic arms are for sale on the market. Robotic arms need to be considered as a great option to improve the product’s productivity and quality.

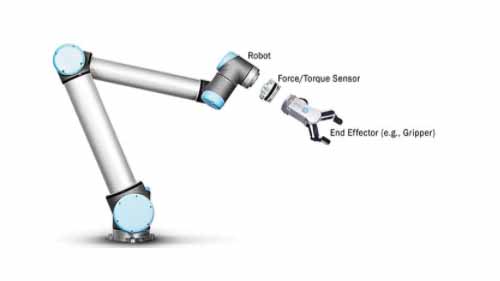

End-effector

An end-effector is a tool device attached to the wrist of a robotic arm. It gives the robotic arm more dexterity and makes it better suited for specific tasks. They are a more convenient solution than having to make a unique robot arm for each role. Examples of end effectors include:

Grippers

Drills

Welding guns

Suction tool

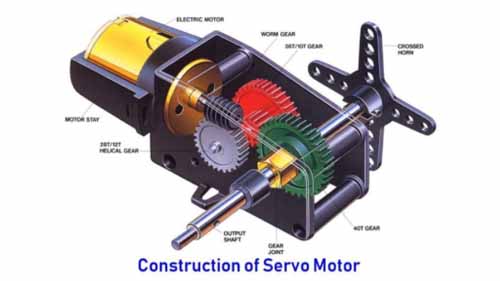

Motors

Source: Pinterest

The parts of an industrial robot need to be powered to move as they can not move of their own volition. For this reason, parts like robotic arms are fitted with motors to facilitate motion. A motor can best be described as an electronic device that has linear and rotary actuators powered by electric, hydraulic or pneumatic energy. As the actuators move at high speed, they push and rotate robotic parts into motion.

Sensors

Source: photonics.com

Sensors in robots are devices that detect or measure specific parameters and trigger a corresponding reaction to them. They are implanted in robot structures for safety and control purposes. Safety sensors are used to detect obstacles to prevent human-robot and robot-robot collisions. They are a more recent addition to robot structures and more particularly, in collaborative robots. Control sensors, on the other hand, are used to receive prompts from an external controller which the robot then executes.

So, how do sensors work? A safety sensor, for instance, will detect an obstacle, send a signal to the controller which in turn slows or stops the robot to avoid a collision. In essence, a sensor always works in conjunction with the controller. Other parameters that robot sensors detect include position, velocity, temperature, and torque.

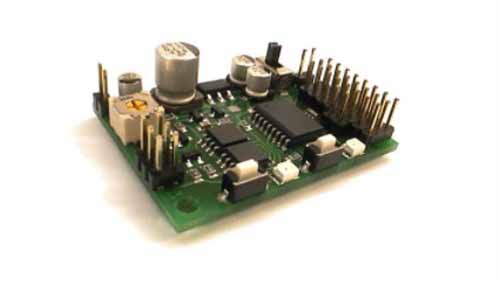

Controller

Source: www.blackrobotics.com

Think of the controller as the brain of a robot. It is the central operating system that controls how all other parts of the robot work. It is programmed with software that enables it to receive, interpret and execute commands. In more advanced robots, the controller can also have a ‘memory’ from which it executes repetitive tasks as it ‘remembers’ how they work. Artificial intelligence in smart robots is also inbuilt into the controller via software.

Conclusion

The quality of parts and the workmanship used to build them into a robot, determine the quality and performance of an industrial robot. This is perhaps what sets a good industrial robot manufacturer apart from the rest. This may be a helpful criterion to use as you choose which industrial robot brands to invest in.