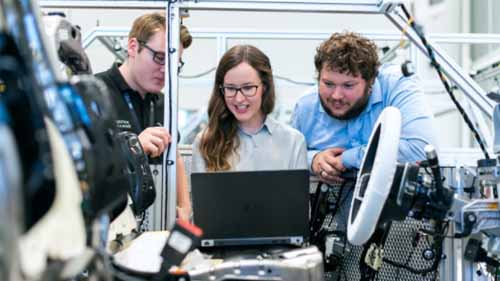

SCARA robots are today an integral part of many production lines in various industries. Due to their speed and accuracy, they have become a popular solution for improving throughput and streamlining manufacturing costs. However, to truly benefit from introducing a SCARA robot into your production line, you need to choose one that suits your needs.

As the robotic industry grows, so has the number of SCARA robot manufacturers in the market. You may, therefore, find yourself overwhelmed by options when it comes to choosing the right SCARA robot. So, to save you from that dilemma, here is a detailed guide to help you make an informed choice.

Table of Contents

What is a SCARA Robot?

Source: robotiq.com

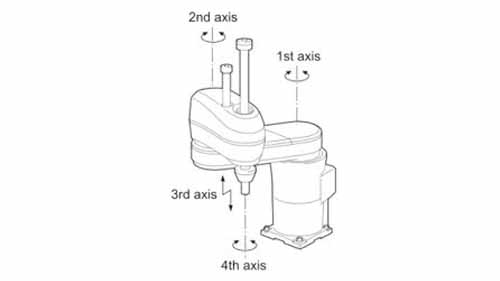

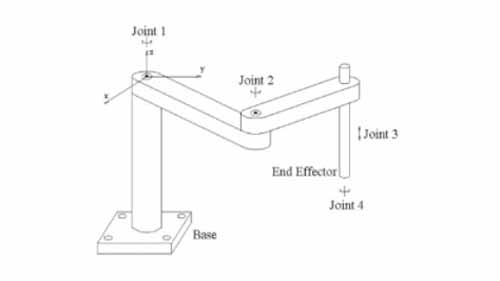

SCARA is an acronym for Selective Compliance Assembly Robot. This acronym represents 2 important facts:

Selective compliance – a scara robot is only flexible in the X and Y axes but is rigid in the Z-axis.

Assembly robot- when the scara robot was invented in 1978 it was solely envisioned as an assembly robot.

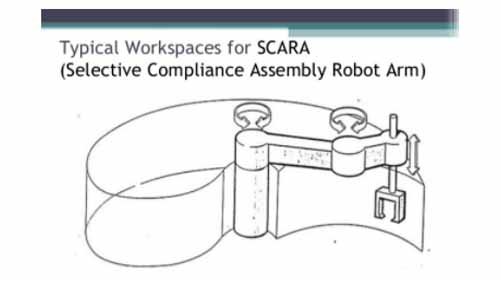

A SCARA robot can thus be described as a robot made up of a 2-part robotic arm attached to a rigid base. The robotic arm is compliant in the X and Y-axis which means it can move back, forth, left, and right. It can also move vertically in a fixed Z-axis and is capable of rotational motion at the wrist.

Over the years, as the designs of scara robots evolved and it began being applied in other ways, the acronym also changed. SCARA is now defined as a Selective Compliance Articulated Robot.

Advantages of SCARA Robots

The limited compliance of scara robots makes them ideal for assembly and pick and place tasks such as material handling. Some of the numerous advantages they bring to production processes include:

Small Footprint

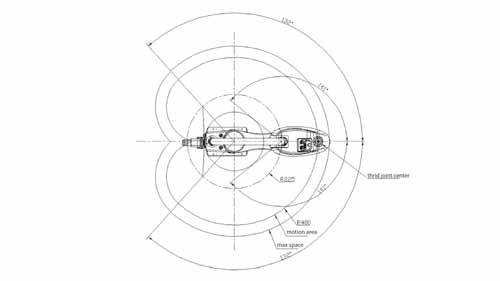

Scara robots have a compact design and perform designated tasks efficiently within a cylindrical work envelope. This makes them easily applicable in situations where space or access to pick and place parts is limited.

In terms of mounting, most scara robots are often placed on a pedestal or movable cart. This provides flexibility for the robot to be moved to different areas whenever necessary.

Speed

The speed of robotic arms is affected by the number of joints involved in their movement. The more the number of joints, the lower the speed a robot arm operates at. This is because:

It takes a longer time to transmit power through the motors in multiple joints.

Longer arms are generally heavier and thus meet more resistance during motion.

Scara robot arms move much faster because they are often 4-axis arms which have fewer joints. You would be hard-pressed to find another robot that delivers cyclical times as short as those of a scara robot. Further, unlike human labor, they do not suffer fatigue or get bored by the repetitive nature of their tasks.

The dimensions of scara robots also aid its speed performance. They have a low center of gravity which greatly reduces the pull of gravity on both the robotic arm and the part being handled. Even in high-pressure industrial settings, you are assured that the rate of output of a scara robot will remain efficient.

Repeatability and Accuracy

While repeatability and accuracy are 2 different characteristics, they are closely tied. Consider, for example, a scara robot that is picking electronic parts from point A to point B. Repeatability refers to the robot’s ability to move between points A and B at a consistent rate of uniform movements. On the other hand, accuracy is a measure of whether the robot reaches the targeted part during each cycle.

Scara robots can deliver repeatability of up to +/- 0.01mm which is quite high and almost impossible to achieve with other robot types. This is mostly because they have fewer motors which reduces room for error during motion.

It is also possible to install vision systems on the robotic arm of a scara robot to further improve its accuracy. They enable the robot to distinguish between different objects during picking which comes in handy for tasks like sorting. Alternatively, where item identification is not an issue, robot sensors can be used to improve motion accuracy.

Synchronization

A scara robot can easily be synchronized with other parts of the production process to facilitate smooth operational processes. Synchronization is aided by their dependable accuracy and repeatability as well as electronic controls like sensors.

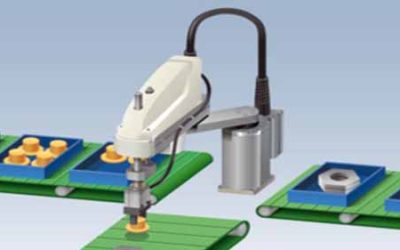

Take, for example, a scara robot arm tasked with picking parts from a conveyor belt and placing them in a packaging box. It would work as follows:

The scara robot arm is fitted with a vision system and placed over the conveyor belt

The parts are loaded on the conveyor belt in uniform spaced intervals

The conveyor belt is started and when the part reaches the robot arm, it is detected by the vision system

The robot arm is thus prompted to pick it and place it in the box

After placement, the scara robot arm returns to its position over the conveyor belt and the cycle continues

This is a general illustration of how synchronization could work. How you choose to synchronize your operation will depend on the nature of the processes involved.

Multi-purpose

Even with the limited motions of scara robots, they can be applied in more than one way. As you weigh your options, do not be boxed in by the idea that a scara robot can only pick and place. Whereas that is the basic principle of their operations, it can be adapted in numerous ways. End-effectors also make a great difference in diversifying the robot’s operations.

Limitations of SCARA Robots

While scara robots are highly efficient, there are limits to what they can accomplish. Here are some limitations worth keeping in mind as you make your purchase.

Restricted Work Envelope

Source: image.slidesharecdn.com

The cylindrical work envelope covered by scara robots is only ideal for a limited number of applications. Furthermore, some tasks may require a different direction of motion or wider reach than scara robot arms can deliver.

Limited Flexibility

Source: veteng.edu.eg

The arms of scara robots are levers and therefore, they only operate in one plane with limited reach. Additionally, the 4th axis at the wrist can only rotate parts in horizontal orientation but cannot tilt them.

If your application requires a larger range of motion, you would be better served by a robot with more flexibility. A 6-axis robot, for instance, offers 3D flexibility and can cover a much larger work envelope.

Small Payload Capability

Source: pexels.com

The design of scara robots is optimized to deliver speed and accuracy in their application. However, it limits the payload that scara robots can handle with optimal capacities being below 10kgs. While different robotic arm manufacturers offer a variety of payloads, higher loads would likely result in operational inefficiencies.

How Would a SCARA Robot Benefit a Manufacturer?

Source: Unsplash

As with all other kinds of automation, it is important to evaluate whether investing in a scara robot would benefit your operations. Aside from the cost of purchasing the robot, there are other costs such as energy consumption. Therefore, to maintain profitability, the benefits need to outweigh the costs.

Let us examine some of the benefits of a scara robot to a manufacturer.

Lower Cost of Production

Source: Pixabay

When you employ human labor to perform repetitive tasks, there are challenges involved. First, the human mind gets bored with such tasks and zones out which could lead to errors. Plus, as the hours progress, fatigue sets in, and the rate of productivity dips. Lastly, to maintain a good rate of productivity, you may need to hire a substantial number of workers.

In contrast, one scara robot can take in the work of multiple employees and work at a fast consistent rate. It would greatly reduce your salary expenses and by extension your production costs.

Shorter Turnaround Times

Source: Pexel

Pending orders or insufficient supply of your products could become a thing of the past if you choose the right scara robot. The high rate of scara robot operations could help the whole production system move along faster. As a result, you could improve your delivery times which would, in turn, improve customer satisfaction.

Ability to Scale Up

Source: Pexel

Most manufacturers with high product demand are constrained by production times. However, once you introduce a scara robot to your production line and production times are shorter, you can scale up. Moreover, you would be able to produce more for less as scara robots do not require extra pay for higher volumes of production. In essence, your cost of labor per unit will hardly be affected.

Improved Staff Safety and Job Satisfaction

Source: Pexel

Repetitive tasks are unrewarding and offer no room for career development. They also require long hours of standing and repeated muscle movement. Unlike robotic joints, the human body is not built to handle such kind of repetitive movement of muscles for long periods. This is partially why factory workers suffer from chronic lower back pain and skeletomuscular ailments.

Additionally, industrial processes produce by-products like choking fumes and steam. Similarly, handling some products between processes is dangerous. This could be due to the dangers presented by being around the processing machine or the product itself being risky to handle.

When scara robots take over these uncomfortable and dangerous material handling tasks it improves staff safety. It also allows employees to take on other job responsibilities that could employ their talents optimally. As a result, job satisfaction also improves.

Fewer Errors

Source: Pinterest

In a production line, errors can be subtle or outright.

Subtle errors are inconsistencies. For instance, if an employee solders two different workpieces, it is unlikely that they would be identical. While it may seem like a negligible detail, subtle errors undermine the standardization of product quality. In some cases, the product may have such a poor finish that it is cast-off as a reject unit.

On the other hand, there are more outright errors such as breakage of parts being handled or wrongful placement.

Using scara robots significantly reduces the chances of errors in your production operation. Their repeatability gives them a precision that is beyond human capabilities and is thus worth investing in.

How to Choose the Right SCARA Robot

With all the features of scara robots in mind, you will finally be faced with picking one that is suitable for your use. Here are some key factors to consider as you make your choice.

Budget

Source: Pinterest

The amount of money you intend to spend will determine the type of scara robot you can get. Fortunately, there is a wide range of options to choose from with prices as low as $6000 to over $25,000. What occasions this vast price difference? Multiple factors play a role in that. They include:

Payload

Speed

Brand

Customization details

Aim for a brand that can offer you value for money such that the quality of the scara robot is commensurate with the price. Look out for value-adding provisions as well like warranty, after-sale support, or assistance with shipment or delivery.

Further, it is advisable to be inquisitive about costs such as maintenance and the availability of parts. Parts that are hard to find tend to be expensive and time-consuming to replace. You would be better suited by a brand that can source the parts for you or already sells them.

All said and done, remember that a scara robot is a long-term investment. It is better to invest in a good quality robot that will offer you long-term returns.

Accuracy

Source: Pinterest

A scara robot is only as effective as its accuracy. As you compare brands, this is one of the details you should be keen on. It is preferable to opt for a brand that offers high accuracy performance of their scara robot.

Most brands state the accuracy details of their scara robots on their product details. You may also find it listed as repeatability accuracy and some brands may quote it in ‘microns’ or ‘mm’. A robot that offers you 10 microns or +/-0.01mm would be a good choice.

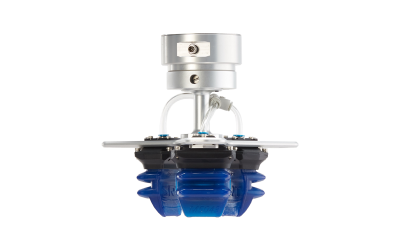

End-effector Compatibility

An end-effector is a device placed at the wrist of a robot arm that is used to handle objects during tasks. Examples include grippers, a solder, a suction device, and many others.

The end-effector you will use depends on the task you need the robot arm to perform. It is therefore essential that the scara robot you choose can accommodate end-effectors for your intended applications.

Further, and perhaps more importantly, examine how the use of an end-effector will affect the cyclical times of the robot. Ideally, the scara robot should be able to handle the end-effector and the load while maintaining efficiency.

Cycle Time

Source: Pexel

The types of motors and reducers used in making a scara robot arm affect its cycle times and overall speed performance. Given the unique placement of scara robot arm joints, they require quality motors to power their movements and sustain high-speed motions.

As you evaluate brands, it would be best to go for one that uses top-of-the-line components that deliver high cyclical times.

Customization Options

Source: Unsplash

Some production lines have unique needs. Factors such as space or the commodities being handled may necessitate some custom design adjustments. If this is the case for your production line, you will first need to find an industrial robot manufacturer that offers customization.

Among the custom options, you could explore:

Branding of your scara robots

Special end-of-arm tooling

Alternative installation options like ceiling mounting

Installing of vision systems

Payload

Source: img.interempresas.net

Your ideal scara robot needs to have a payload that accommodates not just the item but also the end-effector. For example, if the robot will be used to handle items weighing up to 3kg it is best to aim for a payload of 4kgs or 6kgs. If the weight of the part being handled combined with that of the end effector should not outweigh the payload. It would diminish the performance of the scara robot arm.

That said, stay within a reasonable range of payload. Higher payload robots cost more and are a production inefficiency if you do not need the extra capability.

Programming and Control

Source: robodk.com

There are different ways to program scara robots. They include:

Offline mode – in this mode, different motions can be simulated, tested, and installed in the robot system without disrupting production.

Teaching – this method is used for scara robots with sensors. The arm is moved in a series of motions which the sensors ‘learn’ and record as data. The recorded data will be used in the future to fulfill the same task.

Programming Software – programming software is often pre-installed. The controller simply needs to choose a task on a list and the robot will follow guiding commands in the software.

The easier the method of programming, the better. It will save your staff time and enable production processes to run smoothly. Moreover, a scara robot that is complex to program will require you to hire a dedicated programmer as unskilled staff will not be able to navigate its controls.

Further, consider the user interface of the control panel or device. It is advisable to choose a scara robot brand that has a user-friendly control interface to avoid errors and technical challenges. Difficult systems could also become a safety hazard.

Heat Exposure

Source: Pexels

In factories where high-heat processes take place, you may need a scara robot that can cope with such conditions. Welding sparks, for instance, could easily catch onto robot cabling and cause a fire. Consider options such as an explosion-proof scara robot for safety.

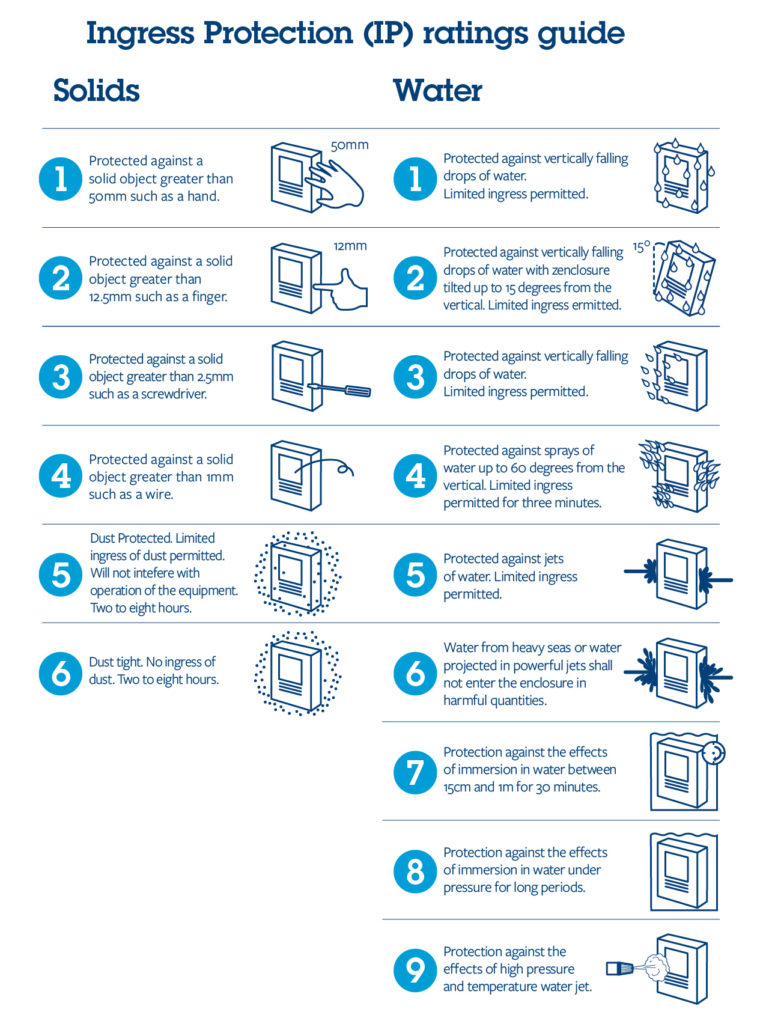

IP Rating

Source: linearmotiontips.com

Industries that handle pharmaceutical products, as well as food and beverages, often require high standards of hygiene. Contaminants such as dust need to be avoided at all costs. It is equally imperative to mitigate against fluid spills which could be hazardous if the robot’s cables are exposed.

An IP-rated scara robot could help you overcome such challenges. Such robots have their cables secured and have waterproof robotic arms for easy cleaning in accordance with hygiene standards. They may also have special protection against dust and rust.

Some robot manufacturers may offer IP-rated scara robots as a standard provision while others offer them as custom options. Either way, if you require such provisions it is best to liaise with your robot supplier.

Application

Source: linearmotiontips.com

The ultimate decision-maker of what kind of scara robot you need is the purpose you intend to use it for. Which begs the question, what can you use a scara robot for?

Process-to-process transfer – this involves the movement of a part from one stage of production to another. For example, the scara robot can collect filled bottles of lotion from a rack and place them on a labeling machine.

Process-to-process transfer that requires inverse handling – inverse handling refers to a situation where the part being handled is better off being lifted from the bottom instead of from the top. For instance: transferring glass slides from one step of production to another is faster and safer if they are hoisted from the bottom.

In scara robots, this is achieved using an end-effector attached to the screw on the Z-axis.

Assembling electronic microparts – electronic devices are made of circuit boards that have hundreds of micropart components. It is a near-impossible task to assemble them by hand hence the importance of scara robots. Due to their precise movements, they can easily and quickly insert microparts without interfering with other fragile device parts.

Soldering- once the microparts are inserted, they need to be secured by soldering. The accuracy of a scara robot arm can be harnessed to perform this task by fitting it with a soldering end-effector.

Laser engraving – using a laser engraving end-effector, a scara robot can produce a great standard of legibility. Once again this is attributed to its rigid controlled motions.

Quality inspection – scara robots can be used to test products such as tablets, keyboards, and phones. The end-effector works as a typing finger while an inspector monitors the responsiveness of the device to input.

The list of applications can hardly be exhausted. There are so many possibilities that can be achieved using various end-of-arm tools and customized modifications. However, for every application, keep in mind the range of motion and payload capabilities of a scara robot to determine if it will be up to the task.

Conclusion

From the outside looking in, the concept of robotics as a whole can seem very complex. It is one of the factors that hinder manufacturers from investing in beneficial assets like scara robots. Nevertheless, when the complexities are demystified it becomes clear that robots are truly the future of manufacturing.

It is always an upper hand to get ahead of your competitors. Now that you have the ultimate guide, all that is left is to find the right SCARA robot for sale.