Introduction

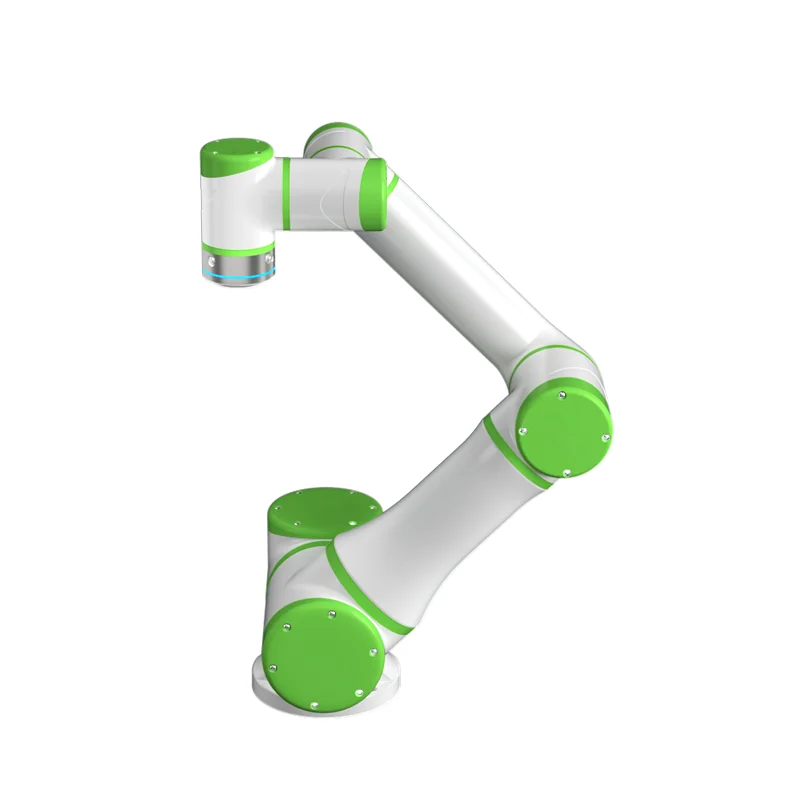

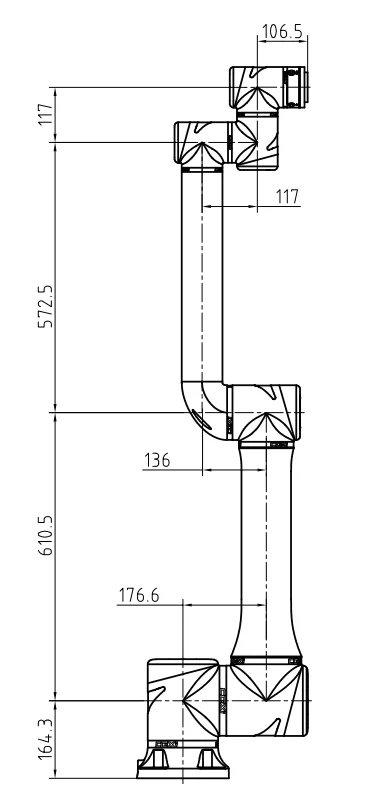

Pick and place robots have played a crucial role in transforming the way distribution centres run in today’s fast-paced world, when efficiency is the key to success. The standards for handling goods and products are being redefined by these automated systems, which are outfitted with cutting-edge technology like artificial intelligence and vision. The “12 kg payload 1300 mm reaching distance 6 axis collaborative robot,” a pinnacle of contemporary robotic engineering intended to enhance the capabilities of distribution centres through smart logistics, is an excellent illustration of this cutting-edge technology.

Functionality of Pick and Place Robots

Pick and place robots, which are renowned for their accuracy and swiftness, are made up of an intricate combination of parts, including a gripper, an intelligent software, and a robot or cobot arm. Collaboratively, these components enable the vital function of precisely moving objects from one place to another. This functionality is demonstrated by the 12 kg payload cobot, whose six axes offer remarkable agility and manoeuvrability in handling, palletizing, and pick and place activities, thereby altering the operational dynamics of smart logistics.

Applications of Pick and Place Robots in Smart Logistics

Pick and place robots have established themselves in the field of smart logistics because to their numerous uses. They play a crucial role in the automation of warehouses and other production and logistical activities. Their responsibilities here include order picking, packing, and sorting, all of which combine to create an exceptionally efficient operational flow. The advent of novel solutions such as the Smart Item Picker, which facilitates single-item selecting, emphasises their essentiality in contemporary logistics arrangements.

Advantages of Pick and Place Robots in Distribution Centers

There are many benefits to using pick and place robots in distribution centres. The output is greatly increased and the overall quality of the work is enhanced by these automated solutions. They successfully handle urgent logistics issues like a lack of labour, varying customer demand, monotonous repetitive work, and health problems for employees. By doing this, pick and place robots, such as the 12 kg payload cobot, provide a more sustainable and healthy work environment in addition to increasing productivity.

The Rising Importance of Collaborative Robots in Distribution Centers

In the spectrum of automated logistics, collaborative robots (cobots) like the 12kg payload cobot have emerged as game-changers. These cobots excel in space efficiency, ensuring safe interactions with human workers, and exhibit remarkable adaptability in existing warehouse setups. Their collaborative feature extends the boundaries of time and space, liberating humans from repetitive and hazardous environments. This harmonious integration of cobots in distribution centers is a significant leap forward in the journey towards smarter, more responsive logistics.

Industry-Specific Benefits of Pick and Place Robots

Pick and place robots have found their footing across various industries, notably in e-commerce, logistics, and fashion. These sectors, characterized by their need for rapid response to consumer demands and handling of diverse product variations, reap substantial benefits from the deployment of these robots. The ability of pick and place robots to efficiently manage large volumes of products while addressing labor shortages is a cornerstone in the evolution of smart logistics in these industries.

Case Studies in Smart Logistics

The real-world applications of pick and place robots offer a glimpse into their transformative impact. A notable case is the Qianjiang QJRB20-1 robot, which leverages teaching-free technology for fast line changes and unmanned digital production of stainless steel cookware. Its energy-saving servo driver and frequency converter notably reduce energy consumption by 10%. Moreover, the robot’s self-developed SCADA system enables remote monitoring of performance rates, speed, maintenance, and updates, exemplifying the advanced integration of pick and place robots in smart logistics.

Conclusion

As we navigate through the rapidly evolving landscape of distribution and logistics, the role of pick and place robots becomes increasingly pivotal. These sophisticated machines, exemplified by the 12kg payload cobot, are not just tools for automation; they are catalysts of transformation. They enhance work quality, scalability, and efficiency, addressing various challenges faced by businesses today. The future of distribution centers, powered by smart logistics and advanced robotic solutions, looks promising, poised to set new benchmarks in operational excellence. Visit EVS Int for more information about smart logistics.