Introduction

Efficiency is a constant goal in the field of industrial automation. SCARA robots and robot tracks are two essential components in this field that have pushed the limits of production productivity and accuracy. This paper explores the combination of the “3kg Payload 400mm 4 Axis Universal SCARA robot EVS3-400″ with the cutting-edge “EVS Robot Track,” showing how this combination expands industrial capabilities and redefines efficiency.

Understanding SCARA Robots

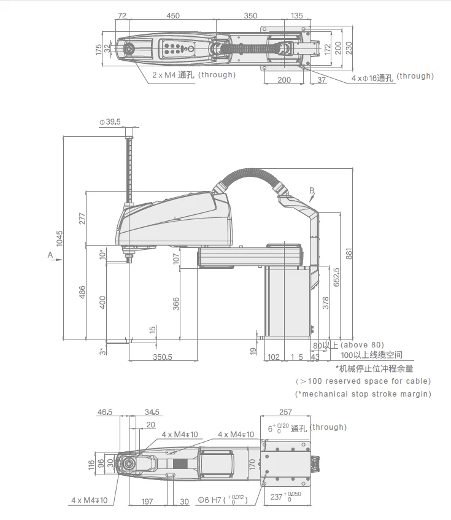

Assembly for Selective Compliance Robots with robotic arms (SCARA), like the EVS3-400, are a major advancement in robotics technology. These robots are intended for precise, fast-paced work in industrial environments. The EVS3-400, with its 4-axis design, is perfect for material handling, assembly, and 3C (computer, communication, and consumer electronics) applications. Its maximum reach is 400mm, and it can handle payloads up to 3kg. The secret to SCARA robots‘ efficiency is its design, which permits selective compliance in the arm, making repeated, accurate motions possible. This is essential for activities demanding a high degree of accuracy.

The Role of Robot Tracks in Expanding Work Envelopes

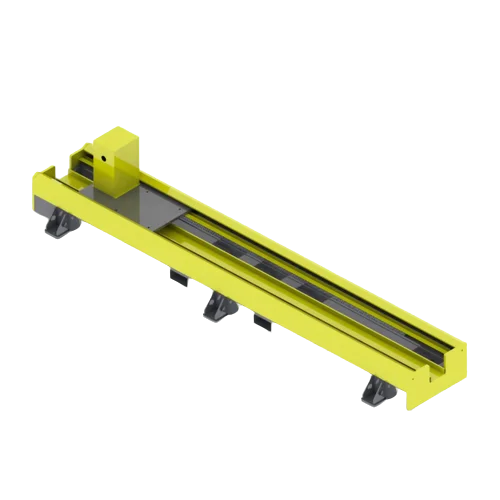

Robot tracks are a game-changer when it comes to improving SCARA robot performance. Similar to the EVS Robot Track, these tracks offer a linear motion technology that lets robots move in a single direction, greatly increasing their work envelopes. Because of their increased range, SCARA robots are more useful for tasks like welding, cutting, handling, and machining. This capacity is further enhanced by the EVS Robot Track, which guarantees that the robot can function effectively in a variety of industrial installations. The track may be customised for length and rated load.

Synergy between SCARA Robots and Robot Tracks

The productivity and adaptability of robotic systems in industrial settings are increased when SCARA robots and robot tracks are used together. For example, the EVS3-400’s working range is greatly increased when it is installed on an EVS Robot Track. A stationary robot would not be able to perform tasks as complicated and varied as they can be with this combination. This greater range and versatility are extremely beneficial for industrial applications, such as massive material handling systems or large-scale assembly lines.

Advantages of Integrating Robot Tracks with SCARA Robots

The integration of robot tracks with SCARA robots brings forth a host of advantages:

Increased Range of Motion and Flexibility

The operational range of the EVS3-400 SCARA robot is significantly increased when robot tracks are added. More adaptable and effective processes are made possible by this extended range, particularly in large-scale industrial applications.

Enhanced Productivity and Efficiency

Robot tracks allow SCARA robots to travel in a straight line, which cuts down on the amount of time needed for a robot to finish tasks over a greater area. Productivity and efficiency significantly increase as a result of this integration.

Customization for Industrial Applications

Robot tracks, like the EVS Robot Track, can be customised in terms of length and load capacity to match the unique requirements of diverse industrial applications. This adaptability makes the robot track a flexible solution that can be used in a range of manufacturing scenarios.

Improved Precision in Repetitive Tasks

Robots that perform repeated tasks with precision are known as SCARA robots. This accuracy is preserved throughout a broader working region when mounted on robot tracks, guaranteeing constant quality throughout the whole manufacturing process.

Challenges and Considerations

While the integration of SCARA robots and robot tracks offers numerous benefits, it also comes with its own set of challenges:

Space Requirements and Cost Implications

The addition of robot tracks requires more space and can incur higher costs. These factors need to be considered when planning the integration of robot tracks in existing manufacturing setups.

Technical Compatibility

Ensuring that the SCARA robot and robot tracks are technically compatible is crucial. This includes considerations around the load capacity, speed, and control systems.

Overcoming Integration Challenges

Customization and advanced engineering solutions are key to overcoming these challenges. For example, the modular design of some robot tracks allows for easier integration with different types of SCARA robots.

Future Trends and Developments

The development of AI and machine learning is going to have a significant impact on the future of SCARA robots and robot tracks. It is anticipated that these technologies would further augment the capacities of robotic systems, rendering them more flexible and cognitive. We should expect increasingly responsive and intelligent robot systems that can adapt to changing manufacturing needs with little assistance from humans.

Conclusion

A notable development in the realm of industrial automation is the pairing of SCARA robots with robot tracks, such as the EVS3-400. Through increased productivity, expanded operating capabilities, and more flexibility in a range of production processes, this combination redefines efficiency. The potential for these robotic systems in industrial applications is only going to grow as technology develops further, opening the door to more creative and effective manufacturing solutions. Visit EVS Int for more information.