Introduction

The introduction of robotics has substantially transformed the course of manufacturing, signifying a transition from labor-intensive procedures to exceptionally automated and streamlined systems. Central to this paradigm shift resides the incorporation of assembly robots, which have evolved into indispensable components of contemporary industrial operations. The purpose of these advanced machines is to optimize efficiency, uphold superior quality criteria, and guarantee occupational security, thereby bringing about a paradigm shift in conventional manufacturing approaches. Such technological progress is exemplified by the QJRB30-1 30kg Payload 1820mm Reaching Distance Robotic Arm. Such as a significant turning point in the evolution of robotics in manufacturing, this assembly robot exemplifies the utmost in accuracy, velocity, and adaptability.

The Proliferation of Robotic Assembly in Manufacturing

The 1960s saw the introduction of the first industrial robots, which is when robotics in manufacturing first emerged. These initial devices established the foundation for an element that would later play a crucial role in manufacturing procedures. Particularly, assembly robots began to acquire prominence as a result of their exceptional precision and efficiency in performing labor-intensive and repetitive tasks. Assembly robot adoption has increased over the years due to their capacity to optimize production lines, lower operational expenses, and improve product quality.

A Technical Synopsis of Contemporary Assembly Robots

Contemporary assembly robots, which are distinguished by their nimbleness and exceptional performance, are indispensable to the ongoing quest for innovation and efficacy in the manufacturing industry. The sophisticated functionalities of these robots empower them to execute an extensive range of duties, spanning from basic assembly procedures to intricate processes necessitating accurate manipulation.

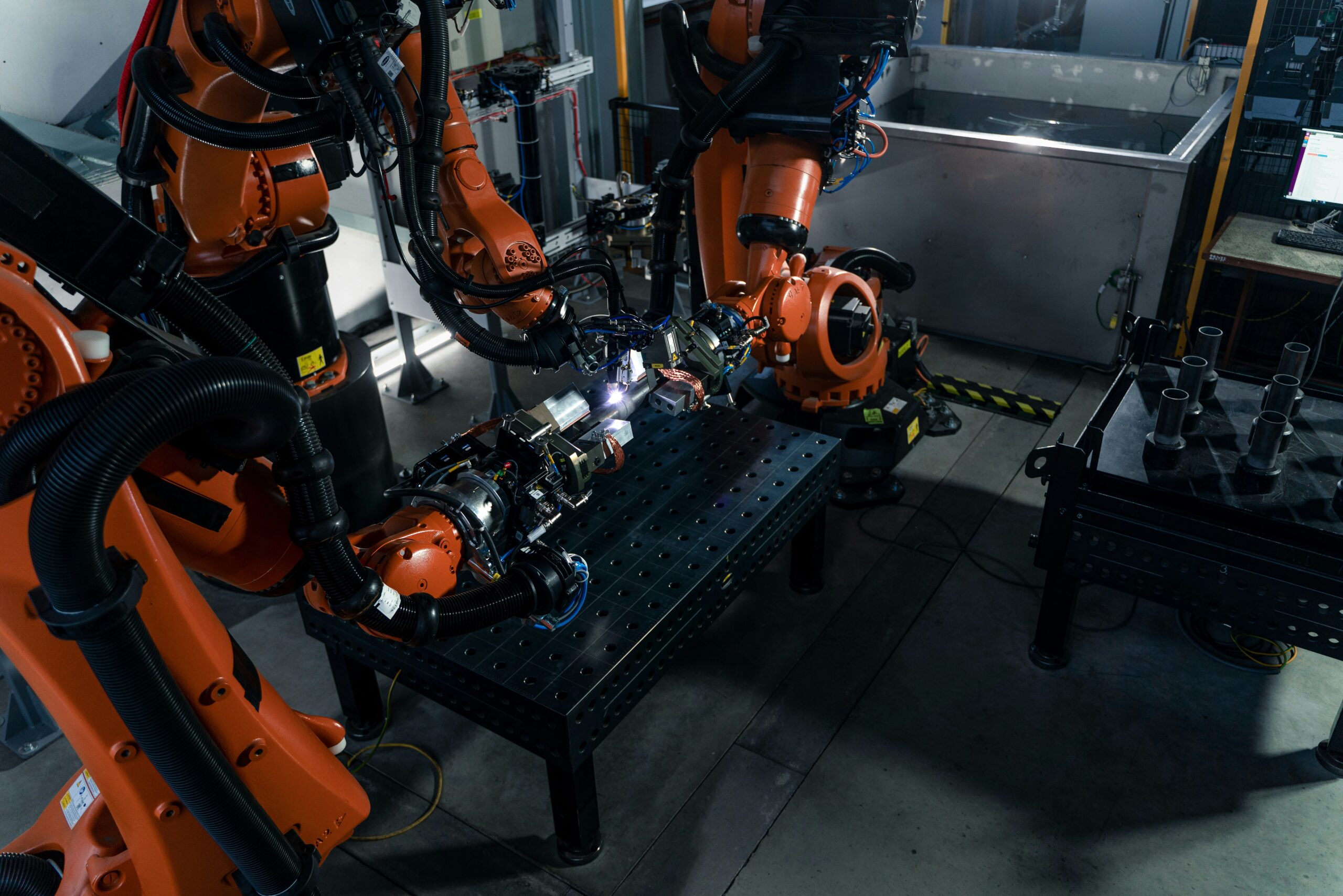

An Overview of the QJRB30-1

Among the most advanced assembly robots is the QJRB30-1 1820mm Reaching Distance Robotic Arm with a 30kg Payload. Characterized by its low power output and stability along all dimensions, this robot is notable for its rapidity. The technical specifications of the QJRB30-1 demonstrate its capability:

Payload

30kg, enabling the machine to manage a diverse array of products and components.

Armspan

1820mm, facilitating expansive coverage of work areas through broad reach.

Repeat Positioning Accuracy

±0.05mm, guaranteeing the execution of operations with the highest degree of precision.

In conjunction with its compatibility with specialized palletizing software and these characteristics, the QJRB30-1 is an exemplary model of contemporary assembly robots.

Advantages of Robotic Assembly in Manufacturing

There are numerous advantages to incorporating assembly robots such as the QJRB30-1 into manufacturing processes. Automated machinery improves the velocity and consistency of task completion, thereby augmenting production speed and efficiency beyond what is achievable through human labor. In addition, assembly robots‘ precision substantially diminishes wastage and enhances the ultimate product’s quality—both of which are indispensable in the current competitive marketplace. Furthermore, assembly robots enhance workplace safety through the automation of monotonous and potentially perilous duties, thereby reducing the likelihood of accidents and alleviating the physical burden on personnel.

Case Studies in Contemporary Production

In numerous industries, the implementation of assembly robots has resulted in substantial gains in efficiency and output. An exemplary instance pertains to the incorporation of QJR6S-1 and QJR6-1 industrial robotics into an advanced manufacturing configuration intended to facilitate the automated insertion and removal of pistons from CNC machine tools.

Project Synopsis

Across two production lines, this undertaking utilized fourteen sets of QJR6S-1 industrial robots and two sets of QJR6-1 industrial robots. The principal aim was to implement automation in the loading and discharging of pistons, a procedure that had historically necessitated substantial manual effort.

The Progressiveness of Technology

The implementation of assembly robots in this manufacturing process resulted in noteworthy technological advancements:

The versatility of robotics in manufacturing was demonstrated when the robots were programmed to manipulate different varieties of pistons without requiring fixture changes.

High Repeat Accuracy and Speed

The assembly robots effectively supplanted manual repetitive labor by virtue of their improved speed and ±0.03mm repeat accuracy. In addition to decreasing labor force by a minimum of 20 individuals, this automation increased output by a minimum of 15%.

This case study highlights the profound influence that assembly robots have on manufacturing processes, demonstrating how the integration of robotics can result in significant improvements in efficiency and decreases in labor expenses.

Conquering Obstacles in the Integration of Robots

Notwithstanding the apparent advantages, the incorporation of assembly robots into manufacturing operations is not devoid of obstacles. One of the challenges encountered by industries is the demand for specialized training for the workforce, in addition to technical complexities and substantial initial investment.

Nonetheless, through strategic planning, ongoing innovation in robotics technology, and the creation of more user-friendly robot programming interfaces, these obstacles are being progressively surmounted. Moreover, the initial challenges are considerably insignificant in comparison to the enduring advantages of increased productivity and decreased expenses, which renders the incorporation of assembly robots an alluring option for manufacturers.

Prospects for Assembly Robots in the Manufacturing Sector

The assembly robots‘ trajectory in the manufacturing sector is positioned for further significant progressions. It is anticipated that the continuous incorporation of machine learning and artificial intelligence (AI) technologies will augment the autonomy and capacity for decision-making of assembly robots, thereby enabling the implementation of manufacturing processes that are more intricate and versatile.

Technological Progressions

There is a high likelihood that future iterations of assembly robots will be outfitted with improved sensory capabilities. This would enable them to more accurately perceive and react to their environment. By encouraging greater cooperation between humans and robots, this will facilitate the investigation of innovative manufacturing processes that merge the most efficient elements of robotic technology with human creativity.

Changing the Face of Manufacturing

The ongoing development of robotics technology will facilitate the expansion of assembly robots‘ prospective manufacturing applications, thereby stimulating additional advancements in production techniques. This process of evolution will have the dual benefit of enhancing industry competitiveness and fostering the development of safer, more sustainable manufacturing environments.

Conclusion

The incorporation of assembly robots into contemporary manufacturing signifies a substantial advancement in the pursuit of production process efficiency, quality, and safety. The advantages of robotics in manufacturing are evident, starting from the demonstrated success in projects automating complex tasks and the high-speed and stable operation of robots like the QJRB30-1. As we contemplate the forthcoming period, the ongoing progression of robotics technology holds the potential to significantly transform the manufacturing domain once more, thereby materializing the notion of entirely automated, intelligent production systems. By adopting these advancements, manufacturers can establish a leading position in the progression of industry, prepared to precisely and nimbly respond to the requirements of the contemporary market.