Introduction

Amidst the dynamic and ever-changing manufacturing environment of the twenty-first century, the implementation of autonomous automation emerges as a seminal progression, substantially augmenting productivity, accuracy, and efficiency in numerous sectors. Six-axis robots and select and place robots have emerged as prominent figures within the wide range of robotic technologies, owing to their distinct capabilities that are customized to suit particular industrial applications. This article conducts a comparative analysis of pick and place robots and six-axis robots in order to assist manufacturers in determining which robotic solution best meets their operational requirements and objectives. By utilizing the QJR20-1600 six-axis collaborative robot and the R12-135S six-axis collaborative robot as case studies, we undertake an investigation to determine which robotic solution is most suitable for your particular application.

Comprehension of Six-Axis Robots

The Multipurpose Nature of Six-Axis Robots

Six-axis robotics, distinguished by their six degrees of freedom, provide an exceptional degree of adaptability and versatility across an extensive spectrum of motion. This particular ability empowers them to execute intricate duties such as welding, painting, assembly, and material management with exceptional accuracy and effectiveness. The versatility exhibited by six-axis robotics renders them indispensable components in the automated manufacturing processes of the present day.

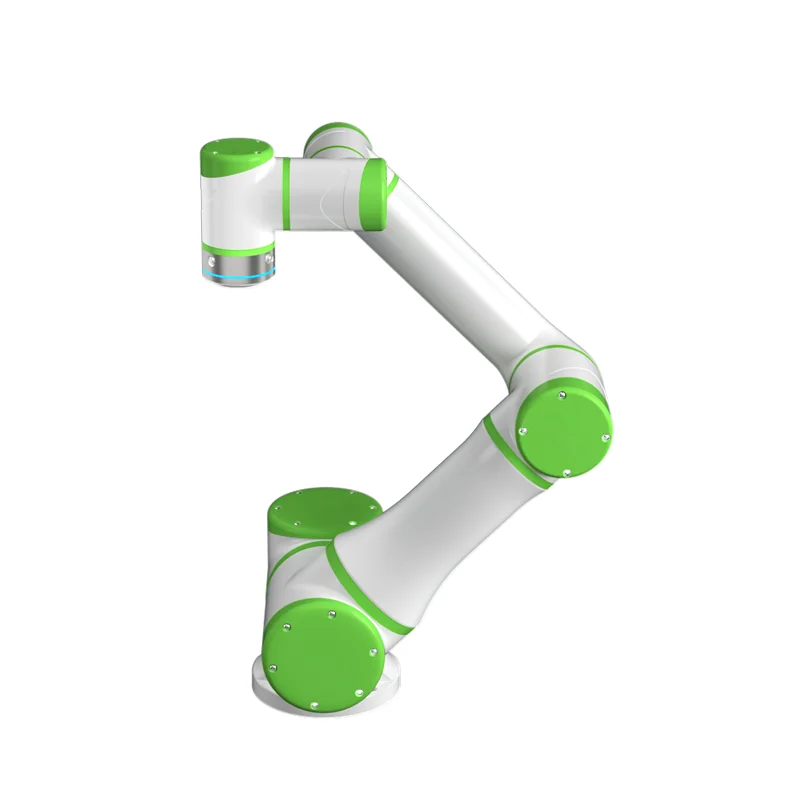

Introducing the R12-135S Collaborative Robot

With a 12kg payload and a 1300mm reaching distance, the R12-135S six-axis collaborative robot exemplifies the specialized capabilities of pick and place robots. Specifically engineered to operate in cooperative settings where human-robot interaction is advantageous, this robot effectively improves both safety and productivity. It is an ideal choice for confined space operations requiring agility and precision, such as palletizing, handling, and arc welding, due to its compact design and high dependability.

Advantages of Manufacturing

Manufacturing processes have been fundamentally transformed by the implementation of six-axis robotics, which provide substantial enhancements in speed, quality, and operational adaptability. The utilization of the QJR20-1600 serves as an illustration of how six-axis robots can augment manufacturing capabilities by integrating the dexterity required for intricate and precise motions with a high payload capacity. Due to this combination of qualities, six-axis robots are ideally suited for sectors that wish to automate complex operations with outcompromising accuracy or productivity.

Investigating Pick-and-Place Robots

Shifting our attention from the general applicability of six-axis robots to the specific domain of select and place robots presents a targeted approach to automation, especially for operations that necessitate rapid, repetitive motions. In applications where the rapid and accurate positioning of items is of the utmost importance, such as assembly lines, material handling, and packaging, these robots are designed with efficiency and precision in mind.

An Examination of the QJR20-1600

The pick and place QJR20-1600 robot serves as an illustration of the sophisticated functionalities inherent in pick and place robot technology. With a remarkable 1668mm reaching distance and a 20kg payload, this robot is engineered to operate at high speeds with an exceptional repeat positioning accuracy of ±0.05mm. The robot’s diversity of functions, which includes palletizing, handling, laser cutting, and sprinkling, demonstrates its broad scope of capabilities. Notably, the QJR20-1600 is the first sprinkling robot to receive national certification featuring an explosion-proof function, demonstrating its appropriateness for hazardous environments.

Positive Aspects of Pick-and-Place Robots

Pick and place robots, such as the R12-135S, are characterized by their capacity to optimize manufacturing procedures by minimizing human error and extending cycle times. The combination of their lightweight construction and ability to function in confined spaces enables versatile implementation across diverse manufacturing environments. Furthermore, the cooperative characteristics of robotic systems such as the R12-135S emancipate human laborers from repetitive and perilous duties, thereby reallocating human capital to more intricate and gratifying positions within the manufacturing ecosystem.

A Comparative Examination

Important Distinctions and Factors to Consider

When deciding between select and place robots and six-axis robots, a number of crucial considerations come into play. Illustrated by the QJR20-1600, six-axis robots provide a wide range of motion and a substantial payload capacity, rendering them well-suited for intricate assignments that demand considerable adaptability and robustness. Conversely, select and place robots, such as the R12-135S collaborative robot, demonstrate exceptional performance in repetitive, high-velocity assignments that demand extreme accuracy and dexterity.

The specific requirements of the application, such as the complexity of the task, the weight of the materials being handled, and the necessity for human-robot collaboration, ought to guide the choice between these two types of robots. In addition, budgetary restrictions, the implementation environment, and the amount of available space are critical factors that can impact the selection of a robotic system.

Acceleration and Accuracy

Although both six-axis robots and select and place robots exhibit remarkable speed and accuracy, their task-specific optimization can substantially impact their applicability. Repeat positioning accuracy of ±0.05mm for the QJR20-1600 renders it well-suited for applications demanding exactitude. Conversely, the R12-135S, boasting collaborative functionalities and a repeat positioning accuracy of ±0.02mm, is ideally suited for tasks that require rapid operation and intimate human-robot interaction.

Application of Industrial Robots in Carton Handling: A Case Study

An instance that exemplifies the collaborative operation of six-axis and pick-and-place robotics is the carton handling procedure. In this particular situation, the unboxing of carton boxes is the duty of a six-axis robot, whereas the palletizing of the products is the responsibility of a select and place robot. This case study illustrates how the utilization of diverse types of robotics can synergistically improve the efficiency and capacity of manufacturing processes.

Results and Insights

The utilization of both types of robots in the carton handling procedure highlights the criticality of assigning the appropriate robot to each individual task. The versatility of the six-axis robot enables it to accommodate carton boxes of varying sizes and shapes, while the speed and accuracy of the select and place robot guarantee the expeditious and accurate palletization of products. This collaboration between robots exemplifies the capacity of robotic automation to revolutionize manufacturing processes by not only streamlining the workflow but also reducing the bodily burden on human laborers.

Selecting the Appropriate Option for Your Application

Assessing Your Necessities

Determining the optimal robotic solution necessitates an exhaustive assessment of the manufacturing process. Take into account the particular duties that require automation, the tangible attributes of the products, and the configuration of the manufacturing facility. In situations where intricate duties involving multiple degrees of freedom or the manipulation of heavy components are involved, a six-axis robot such as the QJR20-1600 might be the most suitable option. A pick-and-place robot, such as the R12-135S, may provide the greatest benefit when performing repetitive, high-speed tasks in a collaborative setting.

Adaptation and Implementation

The efficacy of autonomous automation implementation is contingent upon additional considerations, including seamless integration, scalability, and adaptability to evolving demands. When comparing six-axis and pick-and-place robots, additional factors to consider include personnel training, maintenance needs, and the feasibility of upgrading the robotic system to accommodate novel tasks or products.

Conclusion

The selection between pick and place robots and six-axis robots is a strategic determination that can substantially influence the effectiveness, output, and flexibility of manufacturing processes, rather than being solely a matter of personal preference. Utilizing the distinct functionalities of each robot type and conducting a thorough evaluation of the particular requirements of the application, manufacturers can effectively exploit the complete potential of robotic automation in order to accomplish their operational goals. By capitalizing on the appropriate robotic solutions—be they the adaptability and robustness of six-axis robots or the velocity and accuracy of pick and place robots—manufacturing will continue to evolve to facilitate innovation, streamline production processes, and augment human labor in an ever more competitive environment.

The voyage towards embracing the benefits of robotic automation for manufacturers commences with a definitive comprehension of their operational requirements and a steadfast dedication to investing in the appropriate technology. By taking into account the recommendations and insights presented in this analysis, you will be significantly closer to identifying the most suitable automation solution for your specific application. This will guarantee a future characterized by increased efficiency, excellence, and competitiveness in the dynamic realm of manufacturing.