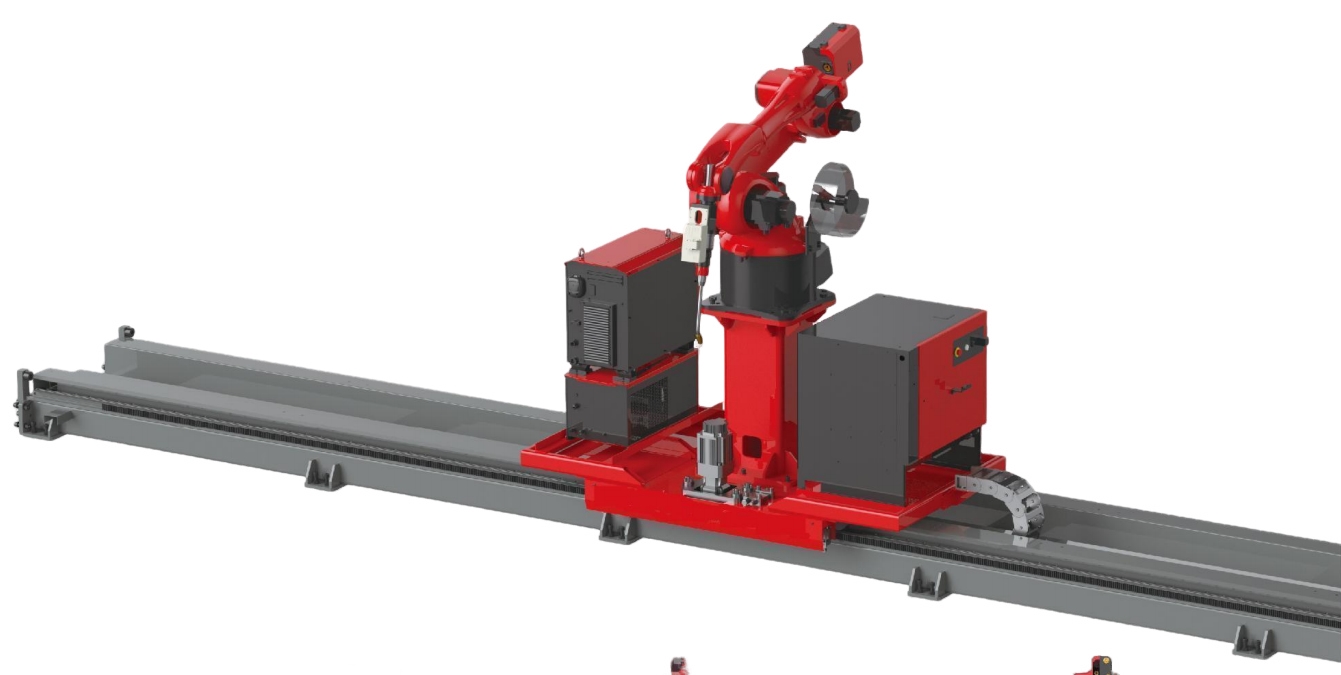

TRACK TYPE

SevenAxis TrackWeld Station

Suitable for welding of slender workpieces, such as H-beams, box beams, etc.

1. An additional seventh external axis is added, with coordinated control between the robot and the track,providing a larger working area;

2.Working areas can be set up on both sides of the track;

3. On the basis of the standard configuration, an additional handling robot is added, allowing for orderly relay operation of welding and handling, effectively improving production efficiency.

| Category | Content | Main Technical Parameters and Range | Remarks |

|---|---|---|---|

| Basic Parameters | Degrees of Freedom | 7 Axes | |

| Maximum End Effector Load | 12kg | ||

| Overall Machine Power | 30KW | ||

| Operational Power Supply | Three – Phase – Five – Wire System 3x380V + 10950Hz | ||

| Visual Performance | Vision (Standard Configuration) | ≤0.5mm | |

| Scanning Frame Rate | 2000 Frames/Second | ||

| Robot Arm Extension Range | R = 2010m | ||

| Mobility Performance | Track Length | 6m/8m/12m/14m/16m | Changes based on robot selection |

| Track Movement Speed | ≥20m/min | Choose according to workpiece situation | |

| Application Environment | Ambient Temperature | 0°C to + 45°C (Operating), – 20°C to + 60°C (Transport and Storage) | Set according to design |

| Relative Humidity | ≤90% RH (Non – Condensing) |