Introduction

The industrial sector, which leads the world in technological innovation, is always looking for new methods to boost output, reduce costs, and simplify processes. Robotic assembly has been one of the major advances in this business in recent years. These advanced machines have revolutionised production lines across numerous industries, but they are most prominently utilised in the difficult component manufacturing sector to create motorgear boxes. Assembly robots are now considered necessary in this field due to their exceptional accuracy and productivity.

This article delves into the transformative impact of assembly robots on motorgear box manufacturing. We will explore how these sophisticated machines optimize production lines, drawing attention to two specific products: the “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600” and the “210kg Payload 2688mm Reaching Distance Robotic Arm QJR210-1”. These examples will illustrate the cutting-edge capabilities of modern robotic arms in enhancing manufacturing processes.

The Evolution of Assembly Robots in Manufacturing

Assembly robots have had an incredible trip through the industrial world. These robots have developed from their first prototypes to the extremely sophisticated ones we see today, playing a crucial role in contemporary industry. Assembly robots were originally created to carry out simple, repetitive activities. However, they have now evolved into sophisticated devices that can accurately and quickly handle complicated processes.

Assembly robots, particularly in the production of motorgear boxes, have replaced many manual processes, leading to significant advancements in productivity and quality. The motorgear box industry, with its intricate and precise requirements, has greatly benefited from the introduction of these robots. Their ability to consistently perform tasks with high accuracy has minimized errors, reduced waste, and increased overall efficiency in production lines.

Product Spotlight – QJR20-1600 and QJR210-1

QJR20-1600: Revolutionizing with Precision and Versatility

One excellent illustration of how sophisticated assembly robots are improving production capacities is the “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600”. With its ±0.05mm repeat positioning accuracy, this robotic arm is exceptionally precise. It is extremely versatile for a variety of applications, including the fabrication of motorgear boxes, as it is specifically built to tackle a range of duties.

Due to its most noticeable feature—its ability to withstand explosions—the QJR20-1600 is an excellent option for settings where security is of the utmost importance. Any manufacturing setting can benefit greatly from its fast working speed and diverse variety of applications, which include polishing and palletizing.

QJR210-1: Catering to Heavy-Duty Requirements

On the other end of the spectrum is the “210kg Payload 2688mm Reaching Distance Robotic Arm QJR210-1”, a powerhouse in the realm of assembly robots. This model is tailored for heavier applications, offering a payload capacity of 210kg. Its extensive reach and high repeat positioning accuracy of ±0.2mm make it perfect for tasks that require both strength and precision.

Applications like welding, palletizing, and, crucially, assembling motorgear boxes, are where the QJR210-1 truly shines. Its ability to maneuver heavy components with precision significantly streamlines the assembly process, reducing time and labor costs while enhancing overall production quality.

Improving Motorgear Box Manufacturing with Assembly Robots

Enhancing Precision and Efficiency

Assembly robots, particularly models like the QJR20-1600 and QJR210-1, have brought about a paradigm shift in motorgear box manufacturing. These robots offer unparalleled precision, a critical factor in producing high-quality motorgear boxes. Their consistency guarantees that every part is put together precisely the first time, thus cutting down on error margin and raising the dependability of the finished product.

Reducing Costs and Increasing Productivity

Assembly robot integration into production lines is strongly associated with increased productivity and decreased operational costs. These robots reduce labour expenses and human error risk by automating labor-intensive and repetitive tasks that would otherwise need manual labour. Furthermore, since they can work nonstop without becoming tired, they can produce at higher rates, which makes it easier to meet manufacturing targets.

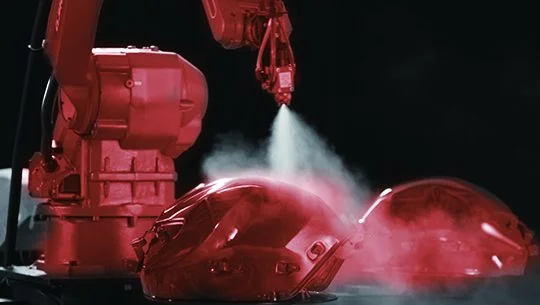

Case Study – Application in Auto Parts Painting

Pioneering in Auto Parts Painting with Assembly Robots

A vivid illustration of the effectiveness of assembly robots in industrial applications is seen in our auto parts painting project. This setup involves two paint robot arms, specifically designed to be explosion-proof, allowing them to operate safely in hazardous environments. The use of assembly robots in this context not only enhances safety but also brings a new level of flexibility and efficiency to the painting process.

Adaptability and Safety of Robots in Challenging Environments

The case study highlights the adaptability of assembly robots like the QJR20-1600 in challenging work environments. Being explosion-proof, these robots can operate in conditions that would pose significant risks to human workers. Their flexibility and ease of programming make them suitable for a variety of painting tasks, which is especially beneficial in the automotive industry, known for its stringent quality and safety standards.

Impact on Efficiency and Quality

The productivity and quality of the painting process have both significantly improved since these robotic arms were put into use. The robots’ accuracy and reliability guarantee that every component is painted consistently, which lowers the possibility of waste and rework. Furthermore, these assembly robots‘ faster operations translate into higher throughput, highlighting the real advantages of robotic automation in production.

Conclusion

Embracing the Future of Manufacturing with Assembly Robots

The integration of assembly robots into manufacturing processes, especially in intricate applications like motorgear box production, marks a significant leap forward in industrial efficiency and product quality. Models like the QJR20-1600 and QJR210-1 exemplify the advanced capabilities of modern robotics, offering precision, versatility, and reliability.

The Transformative Role of Assembly Robots

Assembly robots have not only transformed the way motorgear boxes are manufactured but have also set a new standard in various industrial applications. From enhancing precision to reducing operational costs, the benefits of these robots are clear and far-reaching. As industries continue to evolve, the role of assembly robots will undoubtedly expand, further revolutionizing manufacturing processes. Visit EVS Int for more information.