Light pole welding

This machine has the following major applications in the production of street light poles, as follows:

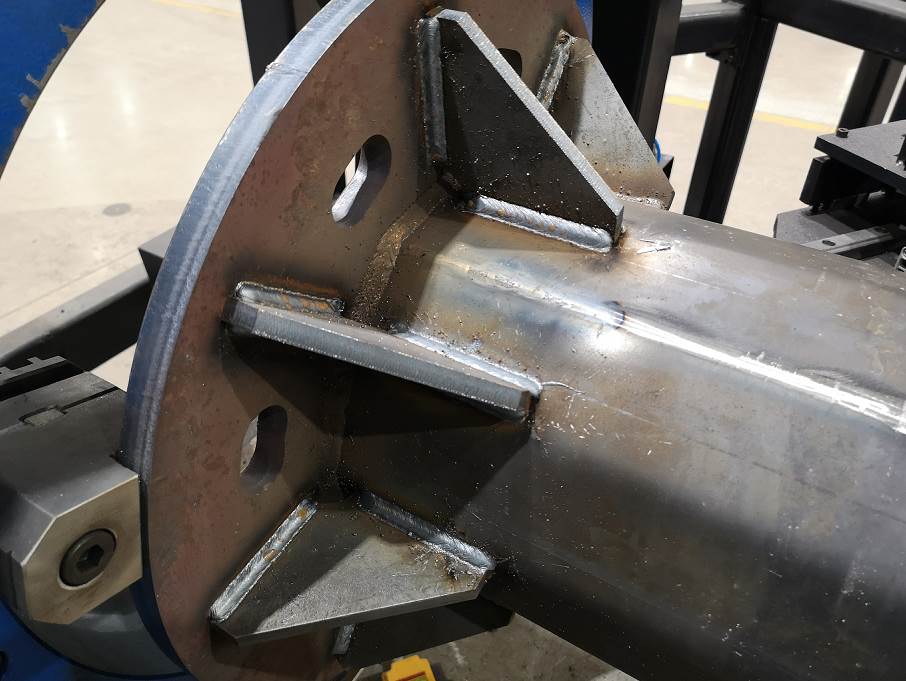

- Positioning and assembly of the bottom base plate,

- Welding the inner and outer seams between the bottom base plate and the pole shaft

- Welding the base plate stiffener,

- CNC door cutting (option function,with Plasma or laser cutting)

- Door frame welding

Suitable for conical poles, round poles, octagonal poles, polygonal poles, equal diameter poles

Main parameter:

| Item | Parameter |

|---|---|

| Pole max diameter | 300mm |

| Pole max.length | 12m |

| Pole min. thickness | 2.5mm |

| Pole max. thickness For welding | For welding :12mm |

| Pole max. thickness (if with door cutting function) | Cutting 8mm |

| The maximum thickness of the expanded tube that can be deformed | 6mm |

| Pole max weight | standard:300kg |

| Max quantity of base plate stiffener | 4~8 Note: If the quantity is large and the spacing of the stiffeners is small and the welding torch is affected, half of the stiffeners can be welded |

| Size of base plate stiffener | Normal street light poles and high mast are suitable (Different sizes of stiffener require different molds, which can be processed and manufactured by the user in accordance with the mold provided in the machine) |

| Welding speed | Reference speed 300~500mm/min Different thickness and different welding speed |

Proprietary features:

- This machine integrates these functions, which can be completed in one loading and unloading: the positioning and assembly of the base plate, the internal and external welding between the base plate and the pole, the welding of the bottom plate stiffener, the electrical door cutting(option), and the door frame welding. The material flow and loading and unloading time between independent processes are greatly reduced, and the production space is saved.

- With pole expansion function, eliminate the gap between the inner hole of the base plate and the pole, and realize automatic welding smoothly

- With the function of automatic placement and welding of the stiffener

- It adopts Japanese Kawasaki Heavy Industries robot with good operability and excellent quality.

- Adopting famous welding power source, good welding seam quality and high welding efficiency

- The positioner has a large turning angle, which can realize the most reasonable angle welding

- Beautiful welding shape and high reliability

- The CNC cutting of the light pole door, the cutting shape can be circle, square, rectangle, oval, etc. Any graphics that can be drawn by computer CAD can be cut by the special software that comes with the machine(option).

- The cutting source is automatic plasma, so the cutting speed will be very fast, and the cut will be smooth and round

- Due to the use of the Hypertherm Powermax plasma source and cutting gun, the cutting gap is relatively small, and the cut pieces can be used as door covers

- After the electric door is cut, if the door frame needs to be welded, the robot can complete the automatic welding of the door frame. And the door frame welding needs to be equipped with the laser positioning function

- The entire machine is designed in the form of a one-way assembly line. The poles are stacked on the left side of the machine. The operator can move one by one to the right to complete the welding, and the welded poles are stacked on the right. The pole moves and rises, no crane is required, and the labor intensity of the operator is low.

- Save a lot of labor costs

- Can adapt to long hours of work throughout the day