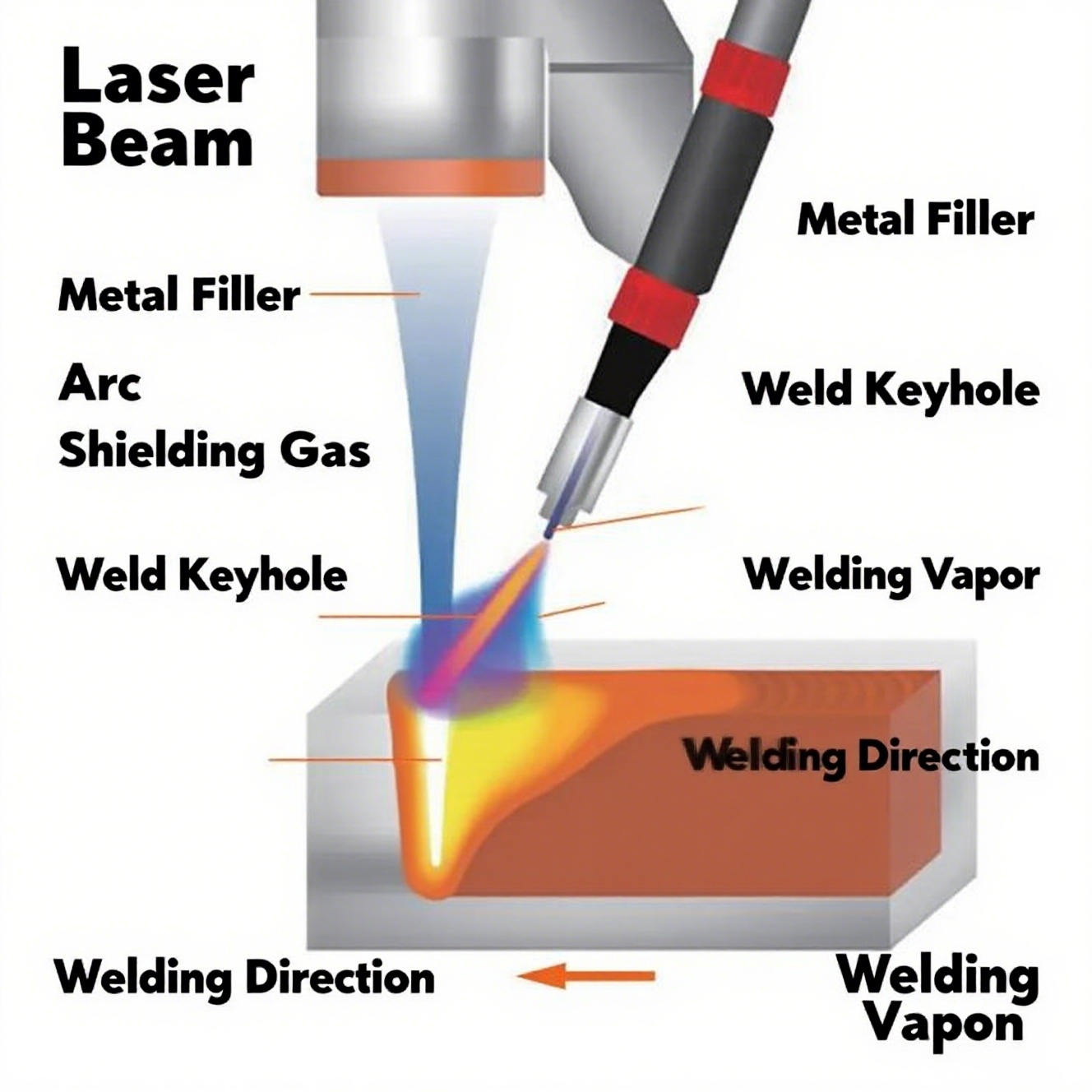

Laser arc hybrid welding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If you encounter problems such as low efficiency, large deformation, difficult welding of thick plates or combining dissimilar materials when welding, laser arc hybrid welding may be one of the most advanced solutions currently available.

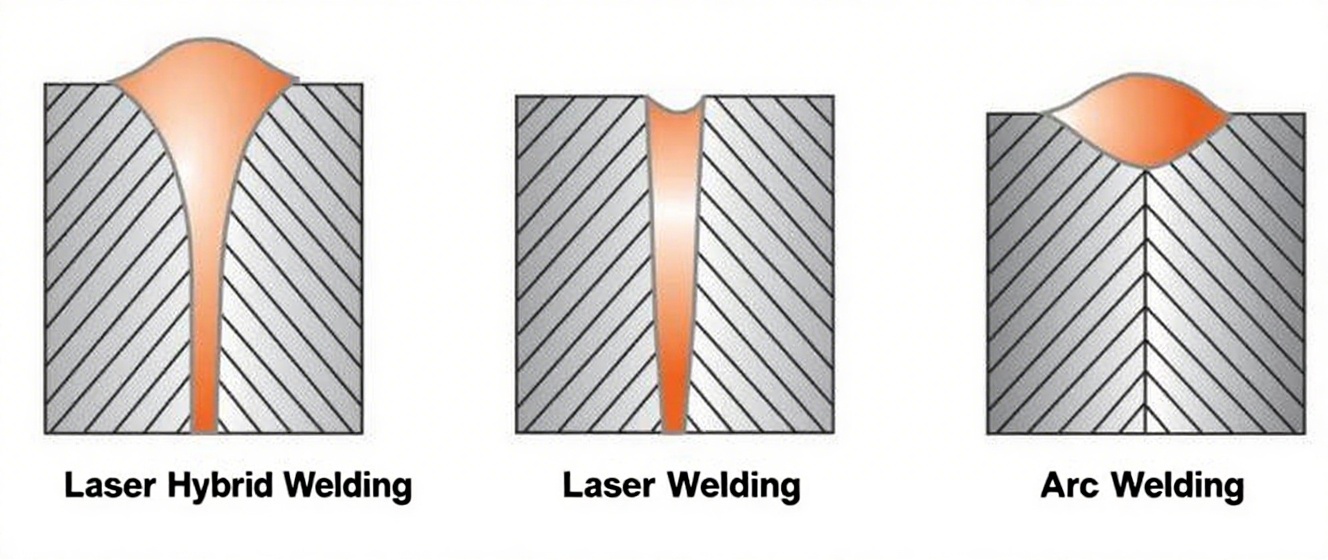

Comparison of the characteristics of laser hybrid welding, laser welding and arc welding

| Laser hybrid welding | Traditional argon arc welding | Single arc welding |

|---|---|---|

| High energy density, large thermal effect | Low energy density, small thermal effect | Moderate energy density, thermal effect |

| Shallow melting depth, higher weld strength for high-precision materials | Deep melting depth, higher weld strength | Shallow melting depth, lower weld strength |

| Non-contact, less restricted by space, certain restrictions on large workpieces | Non-contact, less restricted by space, can weld large workpieces | Contact type, large space restriction |

| Small weld size, can achieve precise welding | Small weld size, can achieve precise welding | Large weld size, difficult to achieve precise welding |

| Operators require a relatively high level of skill | Operators require a high level of skill | Operators require a basic level of skill, easy to train workers |

| Higher equipment cost, need to purchase laser equipment | Lower equipment cost, general argon arc welding equipment | Lower equipment cost, general arc welding equipment |

| The weld surface is smooth, basically no post-weld grinding required | The weld surface is smooth, basically no post-weld grinding required | The weld surface is rough, post-weld grinding required |

Our project implementation cases

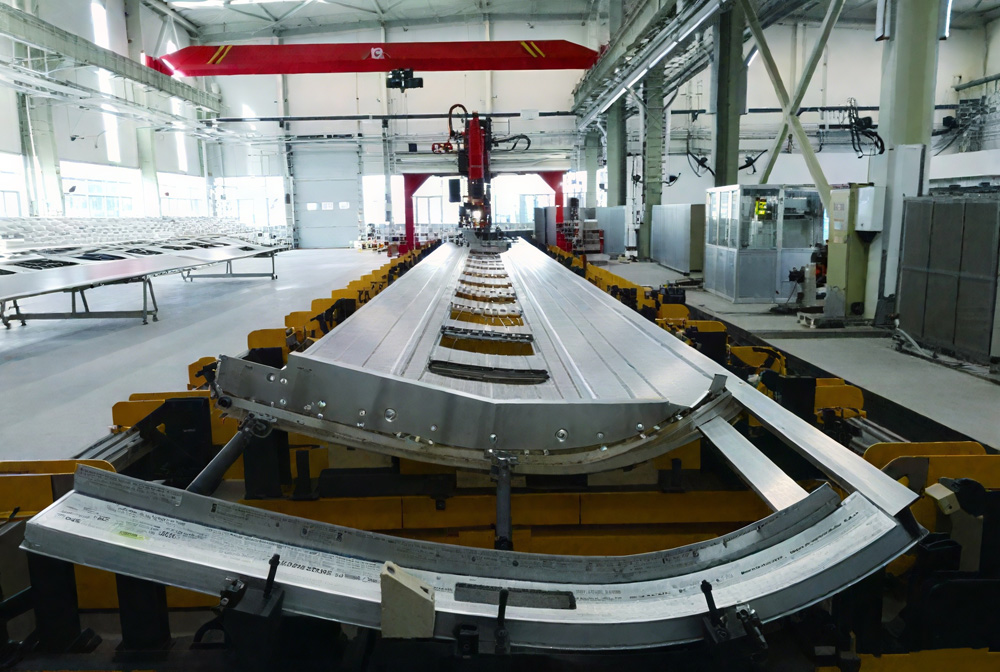

1. Laser arc hybrid welding production line

Application areas and functions

It is primarily used for panel welding on high-end vessels such as ro-ro passenger ferries, yachts, and cruise ships in the marine sector. Laser-arc hybrid welding technology automates and intelligently controls the entire process of plate loading, beveling, assembly, and welding. During the welding process, single-sided welding and double-sided forming can be achieved without hoisting or flipping the plate over. This significantly improves joint strength and toughness, and high welding speeds effectively control welding deformation.

★ Main technical indicators:

(1) Maximum welding area: 10m×10m

(2) Welding plate thickness: 4-15mm

(3) Steel plate conveying speed: 0-6m/min

(4) Groove processing speed: 0.5-1.5m/min

(5) Positioning welding speed: 2-3m/min

(6) Panel welding speed: 1-2m/min

(7) Welding seam heating speed: 1-2m/min

★ User Economic Benefits

This product enables single-sided welding and double-sided forming of large-format ship panels (6-15mm). This improves overall efficiency by six times, reduces welding deformation by over 30%, reduces welding material consumption by over 30%, and doubles welding efficiency.

2. Crane boom laser composite welding workstation

★Applications and Functions

Applied to the welding of high-strength steel booms for truck cranes. This is my country’s first industrial-grade, high-power solid-state laser-conductor arc hybrid welding system for welding high-strength steel booms for cranes, with weld lengths ranging from 12 to 7 meters. CCTV-2’s “China Financial Report: Experiencing Made in China” featured this equipment.

★ Main technical indicators

It is divided into two types: robot workstation and special machine.

Robotic workstation:

(1) Equipment height: Approximately 5.0 m

(2) Gantry rail length (X-axis): 17.0 m

(3) Maximum X-axis speed: 0-10 m/min

(4) Mechanical repeatability accuracy of the ground rail mechanism: ±0.3 mm/m

(5) Welding process: Laser-MAG hybrid welding

(6) Maximum laser power: 10 kW

Dedicated workstation:

(1) The X-axis travel speed of the cross manipulator is 0-5 m/min.

(2) The Y-axis travel of the cross manipulator is 1.5 m and the travel speed is 1.5 m/min.

(3) The Z-axis travel of the cross manipulator is 2 m and the travel speed is 1.5 m/min.

★User economic benefits

Single-sided welding and double-sided forming are achieved under complex working conditions, welding material consumption is reduced by 50%, welding efficiency is increased by 100%, welding deformation is reduced by nearly 50%, workers’ labor intensity and working environment are significantly improved, and the stability of product welding quality and production efficiency are significantly improved.

3. Rail transit laser equipment

★ Application areas and functions

Applied to welding production in the rail transit sector. The system utilizes a gantry structure (ground rail or overhead rail), with the robot suspended upside down on the gantry beam. The 11-axis kinematic mechanism coordinates and enables laser welding, laser welding with filler wire, laser-arc hybrid welding, and laser 3D cutting. It is primarily used for welding aluminum alloy vehicle body components and aluminum alloy profiles.

★Main technical indicators

(1) Gantry clearance height 2900mm

(2) Gantry clearance width 4800mm

(3) Repeatability ±0.08mm/m

(4) Floor rail travel 20000mm

(5) X-axis maximum speed: 0-10m/min

★User economic benefits

Welding deformation is reduced by nearly 50%, welding efficiency is increased by 100%, and the stability of welding quality and welding efficiency are significantly improved.

4. Highly flexible laser welding system

★Applications and Functions

Applied to welding production in the aerospace industry. This system utilizes a ground-based slide-type robot structure and is designed for girth welds on thin-walled cylindrical and thick-walled tubular shells, including heads, barrels, and tailpieces. It achieves precise fillet welds between external components and the shell.

★ Main technical indicators

(1) Laser power: 8000W

(2) Linear axis travel speed: maximum 10m/min

(3) Repeat positioning accuracy ±0.05mm

(4) Positioning accuracy: ±0.1mm

(5) Head and tail frame positioner: Φ40~Φ1000mm

(6) Maximum rotation speed of head and tail frame positioner: 10rpm

★ User economic benefits

Welding deformation is reduced by nearly 30%, welding efficiency is increased by 100%, workers’ labor intensity and working environment are significantly improved, and the stability of product welding quality and welding efficiency are significantly improved.

5. Robotic laser welding equipment for thick-walled complex structural parts of large crawler cranes

★Applications and Functions

Applied to welding production in the construction machinery sector. This system features a single-beam overhead rail-mounted, inverted robotic system. It is primarily designed for automated welding of large, critical structural components on 300-3600t crawler cranes. The maximum workpiece length is 13.6 meters, the maximum weight is 50 tons, and the plate thickness is 20-60mm. This welding equipment is suitable for welding large, complex structural components.

★ Main technical indicators

(1) 3D side gantry travel: 22m×8m×9m

(2) Robot body walking speed: 0.01~10m/min

(3) Robot external axis (X, Y axis) walking speed: 0.1~5m/min

(4) Robot external axis (Z axis) walking speed: 0.1~0.5m/min

(5) Gantry walking accuracy: ±0.2mm

★ User economic benefits

Welding deformation is reduced by nearly 50%, welding efficiency is increased by 100%, welding material consumption is reduced by 50%, welding efficiency and quality are significantly improved, and workers’ labor intensity and working environment are significantly improved.

6. Plate heat exchanger laser welding and cutting production line

★ Application Areas and Functions

Primarily used in heat exchanger welding and cutting production. It automates the entire process, including workpiece loading, turning, assembly, transfer, long and short edge laser welding, post-weld edge laser cutting, and unloading.

★ Key Technical Specifications:

1. Maximum Workpiece Size: 20m x 2m

2. Welding and Cutting Thickness:

3. Welding Speed:

4. Cutting Speed:

★ User Economic Benefits

The integrated welding and cutting production line ensures high-quality welding and cutting, reduces labor requirements, effectively lowers production costs, and improves productivity.