Introduction

Profound advancements in automation have ensued due to the perpetual transformation of the manufacturing industry and its quest for precision and effectiveness. Six-axis robots, one of the most revolutionary advancements, have brought about a fundamental revolution in industrial operations. Due to their remarkable flexibility and skill, these robots are indispensable in enhancing pick and place robot processes, which are fundamental to modern manufacturing. By employing the QJR20-1600 and the R6-093S as case studies, this article will analyze the manner in which pick and place robot operations are enhanced by six-axis robots.

Comprehending Robots with Six Axis

Robotic arms comprising six-axis robots have six degrees of freedom, which empowers them to move along six discrete axes, as their nomenclature suggests. The remarkable precision with which they execute complex tasks can be attributed to their adaptability. Six-axis robots deviate significantly from conventional robotic arms in that they are capable of reproducing the motion of the human arm. This characteristic renders them exceptionally well-suited for the execution of complex tasks. Advanced control systems and sensors are incorporated into these robots to guarantee their precision and dependability.

The notable agility exhibited by six-axis robots is largely attributable to their capacity for rotation along multiple axes. Furthermore, apart from straightforward pick-and-place operations, their design enables the implementation of an extensive range of procedures, such as intricate welding and assembly processes. Due to their remarkable versatility, six-axis robots are implemented in numerous industries, such as retail, pharmaceuticals, electronics, and logistics.

The Principles of Pick and Place Robot Techniques

Pick and place robot operations entail moving items from one area to another. In manufacturing, packaging, and distribution, this seemingly straightforward task is essential. The efficacy and accuracy of pick and place robot operations have a direct influence on the overall profitability and quality of the manufacturing process. Prior to this, these tasks were executed manually, leading to the occurrence of errors and incongruities.

Labor-intensive and prone to human error are the tasks associated with manual pick and place robot. Fatigue among employees can result in lower output and more errors. Furthermore, occupational injuries may result from repetitive tasks. These issues are addressed by the integration of pick and place robot robots, which automate the procedure and guarantee efficiency and consistency.

Pick and Place Robot Operations Using Six-axis Robot Integration

An important development in automation is the use of six-axis robots in pick and place robot procedures. The increased speed, accuracy, and efficiency of these robots are just a few advantages. Six-axis robots lower the possibility of product damage by easily handling complex and delicate tasks. They can operate at rapid speeds without sacrificing accuracy.

The fact that six-axis robots can work nonstop without getting tired is one of their biggest benefits. Productivity rises significantly as a result. These robots’ accuracy also reduces the possibility of mistakes, guaranteeing that products are handled accurately and reliably. In the electronics industry, for instance, six-axis robots are utilized to place small components on circuit boards with extreme precision and care—a process that would be laborious and time-consuming for human workers.

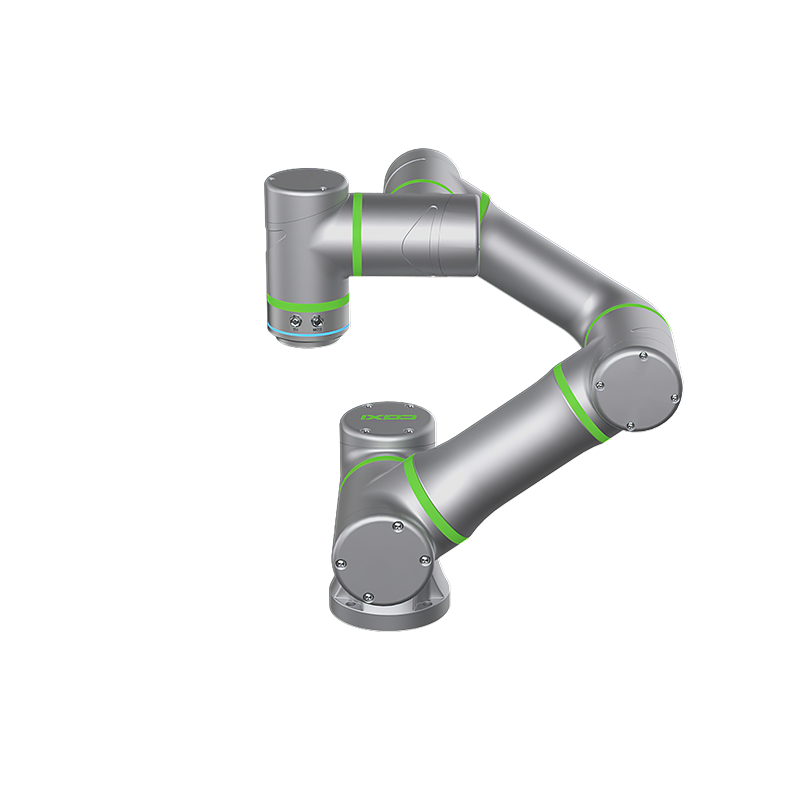

Highlight of the Product: QJR20-1600

In the field of six-axis robots, the QJR20-1600 is unique. Its 20 kg payload and remarkable 1668 mm reaching distance are its main features. Being the first nationally certified spraying robot with an explosion-proof feature, this one is perfect for dangerous environments. Its vertical multi-joint design, which increases mechanical stability, is one of its many simple and compact design features.

Palletizing, handling, loading and unloading, laser cutting, spraying, and polishing are just a few of the many applications where the QJR20-1600 excels. Reliable performance is ensured by its high running speed and ±0.05mm repeat positioning accuracy. When using volatile substances in applications like spraying, the explosion-proof feature offers an additional degree of safety.

The QJR20-1600’s technical specifications consist of:

20 kg is the payload

Reposition in the same location Reliability: ±0.05mm

Maximum Armlength: 1668 Millimeters

Axis Position: Six

Motion Range: J1 (±172º), J2 (√147º,−115º), J3 (√83º,−98º), J4 (±167º), J5 (±115º), J6 (±360º).

Maximum Speed: J1 (154º/s), J2 (154º/s), J3 (171º/s), J4 (355º/s), J5 (355º/s), J6 (355º/s)

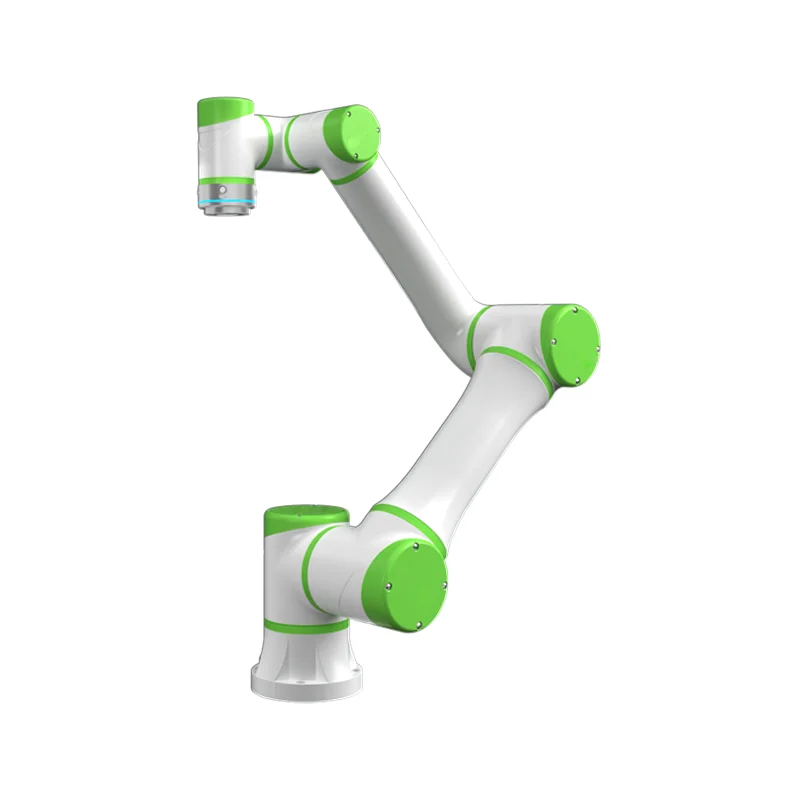

Focus on Products: #R6-093S

Another excellent six-axis robot made for cooperative tasks is the R6-093S. This robot is ideal for handling, palletizing, pick and place robot, and arc welding tasks because it has a 6 kg payload and a 917 mm reaching distance. Because of its lightweight and compact design, the R6-093S is renowned for its exceptional performance and dependability, especially in confined spaces.

With its collaborative feature, the R6-093S can operate in tandem with humans, increasing both operational time and space and relieving workers of dangerous and repetitive tasks. Its precise operations are ensured by its 0.02mm repeat positioning accuracy. This robot has a wide range of potential applications due to its adaptability and capability of being installed at any angle.

The R6-093S’s technical specifications consist of:

Payload: six kilograms

Reposition in the same location Maximum Armspan: 917mm Accuracy: ±0.02mm

Six degrees of freedom

Motion Range: Joint 1 (±360°), Joint 2 (±360°), Joint 3 (±165°), Joint 4 (±360°), Joint 5 (±360°), Joint 6 (±360°).

Maximum Speed: 210°/s for Joints 1, 2, 3, and 4; 360°/s for Joints 4, 5, and 6;

In contrast: QJR20-1600 in contrast to R6-093S

A number of significant distinctions and similarities between the QJR20-1600 and the R6-093S become apparent. With a 20 kg payload and a 1668 mm reaching distance, the QJR20-1600 is meant for heavy-duty work. It is appropriate for dangerous environments because of its explosion-proof feature, especially for spraying applications.

By comparison, the R6-093S is designed for cooperative operations in small areas, boasting a 6kg payload and a 917mm reaching distance. For jobs requiring a high degree of precision and flexibility, like pick and place robot operations and arc welding, its lightweight and compact design makes it perfect.

With the QJR20-1600 measuring ±0.05mm and the R6-093S measuring ±0.02mm, both robots provide excellent repeat positioning accuracy. The particular requirements of the application will determine which of the two is best. The QJR20-1600 is the better option for demanding, dangerous tasks. The R6-093S performs exceptionally well in tasks requiring collaboration and high precision in small areas.

Examples of Case Studies

Take a look at these case studies to see how six-axis robots are used in real-world situations:

Case Study 1: The Production of Automobiles

The QJR20-1600 is used to palletize and handle heavy components in an automotive manufacturing facility. Its precision and large payload capacity have greatly boosted output while lowering errors. Safety is guaranteed when spraying automotive parts thanks to the explosion-proof feature.

Case Study #2: Assembling Electronics

The R6-093S is used for pick and place robot operations involving delicate components in an electronics assembly facility. Its small size and exceptional precision enable it to operate effectively in confined spaces, accurately positioning small components on circuit boards. It can cooperate with human operators thanks to the collaborative feature, which improves workflow in general.

Case Study 3: Packaging of Pharmaceuticals

Both the QJR20-1600 and R6-093S are utilized in a pharmaceutical packaging facility. While the R6-093S is utilized for precise pick and place robot tasks, guaranteeing that every package is precisely filled and sealed, the QJR20-1600 is used to handle bulk materials. By integrating these robots, efficiency and consistency have increased, guaranteeing high standards of safety and quality.

Prospects for the Advancement of Six-axis Robotics and Pick and Place Robot Operations

With ongoing technological developments, pick and place robot operations and six-axis robotics have a bright future. The fusion of artificial intelligence and machine learning is one of the emerging trends that will allow robots to operate autonomously on ever-more-complex tasks. Accuracy and adaptability will be further enhanced by improved sensors and vision systems.

As they enable effortless collaboration between humans and robots, collaborative robots, or cobots, are expected to gain greater prevalence. Through this collaboration, pick-and-place robots will gain increased efficacy and adaptability.

The ultimate goal is for six-axis robots to be utilized in smart factories on a permanent basis, performing the majority of tasks with unparalleled precision, velocity, and dependability. This shift will precipitate a revolution in the manufacturing, logistics, and other sectors, stimulating innovation and productivity.

Conclusion

In contemporary industrial operations, six-axis robots are a necessity, especially for pick and place robot jobs. They are perfect for a variety of applications due to their efficiency, accuracy, and versatility. The six-axis robotics advancements are best demonstrated by the QJR20-1600 and R6-093S, which each provide special features and advantages for particular industrial applications.

Six-axis robots will become more and more important in pick and place robot operations as technology develops, opening the door to more automated, effective, and secure manufacturing procedures. Businesses that adopt these innovations will surely acquire a competitive advantage, guaranteeing their survival in the quickly evolving field of contemporary manufacturing.