Introduction

Significant advances in manufacturing processes have been propelled by the evolution of robotics, which has revolutionized industrial applications. The significance of robotics, specifically in finishing processes, escalates in tandem with the ongoing industry demand for greater accuracy and productivity. Two contemporary technologies that are having a significant impact on the future of industrial finishing are SCARA robots and polishing robots. Due to their unparalleled precision, velocity, and dependability, contemporary manufacturing is inextricably linked to these advanced robotic systems.

These technological revolution is led by polishing robots and SCARA robots, which offer solutions that improve both quality and productivity. By highlighting their advantages, applications, and future developments, this article examines the integration of these two technologies.

The Definition and Operation of Polishing Robots

With the intention of automating the polishing procedure in a variety of industrial settings, polishing robots are specialized robotic systems. By virtue of their sophisticated control systems and sensors, these robots are capable of carrying out polishing operations with accuracy and consistency. To achieve the intended texture and appearance, the principal functions of polishing robots are deburring, smoothing, and surface finishing of materials.

Positive Aspects of Polishing Vehicles

Numerous benefits are associated with the implementation of polishing robots:

Polishing robots guarantee a heightened level of accuracy and consistency by removing the possibility of human fallibility and incongruity during the polishing procedure.

Companies can achieve a reduction in labor expenses and mitigate worker fatigue by implementing automation in the polishing process, thereby diminishing their dependence on manual labor.

Enhanced Safety: Hazardous materials and environments are frequently encountered during polishing operations. The risk of worker injuries can be reduced by having polishing robots execute these duties in a secure manner.

Diverse Industry Applications

There are numerous sectors in which polishing robots are implemented, such as:

For the purpose of polishing automobile components and bodies.

Used in electronics to adorn fragile electronic components.

To attain precise surface finishes on components used in the aerospace industry.

QJR20-1600 is a highlighted product.

Showcasing advanced polishing robots is the QJR20-1600 robotic arm. With an explosion-proof feature, it is the first nationally certified spraying robot available. Principal attributes of the QJR20-1600 consist of:

Transporting substantial loads with a payload of 20 kilograms.

A 1668mm reaching distance enables a wide range of applications to benefit from its extensive reach.

Precise and consistent performance is ensured by the high repeat positioning accuracy of ±0.05mm.

Palletizing, loading and unloading, laser cutting, spraying, and polishing are among the numerous applications for which this product is versatile.

Modern industrial polishing requirements are well-suited for the QJR20-1600 due to its adaptability, high operating speed, and simple and compact mechanical design.

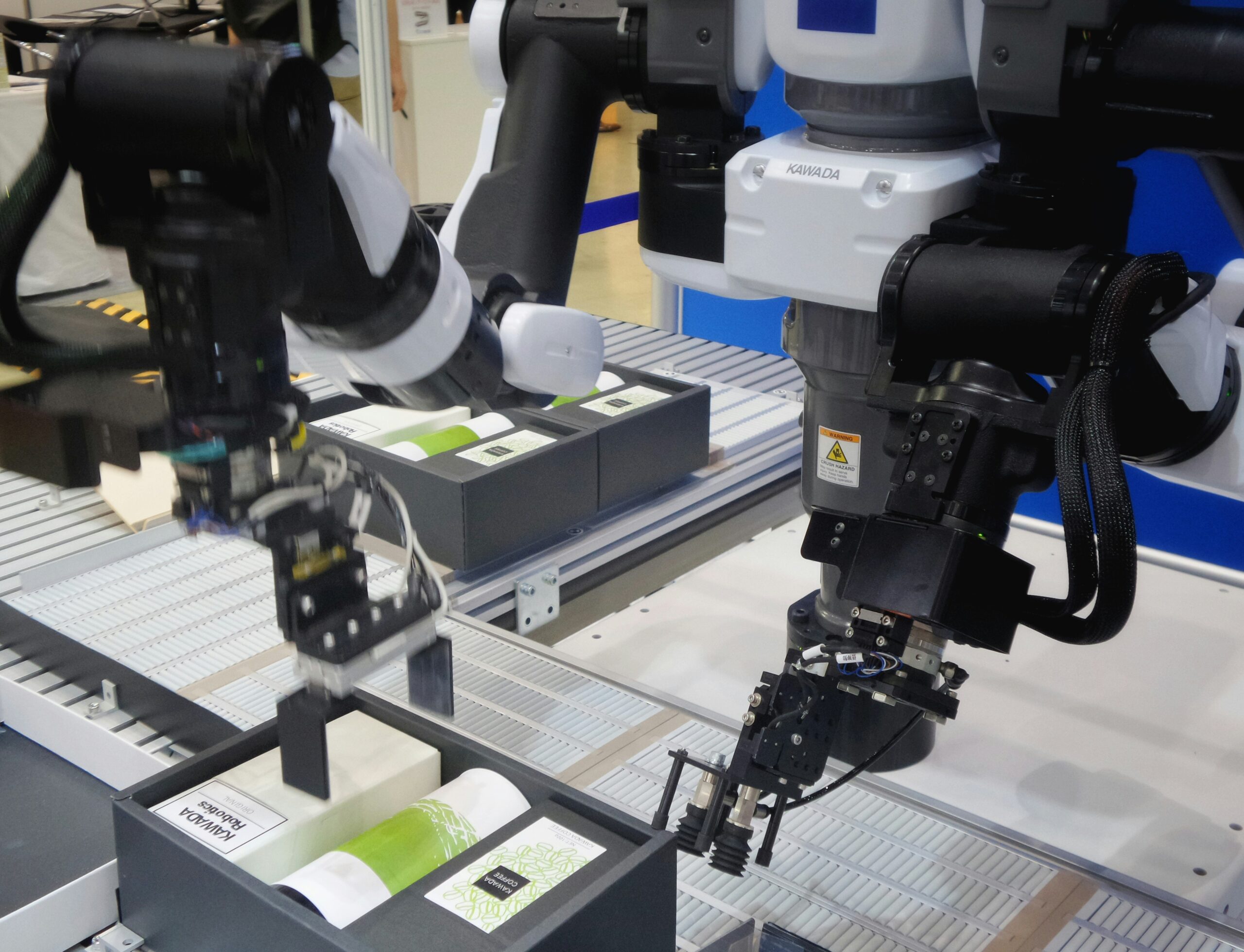

The Definition and Operational Scope of SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are designed within industrial settings to perform tasks that require extreme precision and velocity. Owing to their nimble and compact design, these robots are capable of carrying out assembly, handling, and palletizing operations with extraordinary precision. The horizontal arm movements of SCARA robots render them well-suited for applications that demand accurate lateral motion.

One of the benefits of SCARA Robots

SCARA Robot advantages consist of the following:

SCARA robots have the capacity to optimize the manufacturing process by performing tasks with exceedingly high levels of precision and velocity.

The design of these systems enables smooth integration into established production lines, thereby obviating the necessity for significant modifications. Moreover, their structure is both compact and adaptable.

SCARA robots provide precise motion and quiet operation, both of which are essential for intricate assembly tasks due to their high transmission accuracy and low noise output.

Diverse Industry Applications

There are numerous industries in which SCARA robots are utilized, such as:

For the assembly of diminutive electronic components.

Sorting and packaging at a rapid rate of operation.

Used in the automotive industry to assemble and manipulate components.

EVS3-400 is the featured product.

Prominent among light-duty SCARA robots is the EVS3-400 SCARA. Principal EVS3-400 characteristics include:

Capable of towing light loads, the 3kg payload is adequate.

Effective operation in a confined workspace is ensured by the 400mm maximum reach.

Accomplishing repeated positioning accuracy of ±0.01mm with high speed and precision.

Handling, palletizing, assembly, and sorting are a few of the applications that can benefit from its adaptability.

The EVS3-400 SCARA robot is engineered to efficiently execute contemporary industrial tasks with precision, timeliness, and dependability, owing to its nimble and adaptable construction.

The Synergy Between Technologies in the Integration of Polishing Robots and SCARA

Synergy is generated that increases overall productivity and efficiency when polishing robots and SCARA robots are integrated into industrial processes. In contrast to SCARA robots, which excel at assembly and handling at high speeds, polishing robots excel at tasks requiring precise surface finishing. The integration of these technologies into production lines enables manufacturers to optimize assembly processes and guarantee superior quality.

Increased Productivity and Efficiency

Profound enhancements in efficiency and productivity result from the integration of SCARA robots with polishing robots. By utilizing both types of robots, for instance, a production line can attain increased throughput and accelerated cycle times. SCARA robots oversee assembly and material handling, thereby ensuring a streamlined and effective workflow, whereas polishing robots are adept at producing precise surface finishes.

Integration Illustrated through Case Studies

The integration of SCARA robots and polishing robots has been effectively demonstrated in a number of case studies.

In order to automate the assembly and finishing of automobile components, a leading automaker integrated SCARA and polishing robots. A reduction in defects of 25% and an acceleration of 30% were the outcomes of this integration.

An electronics manufacturer utilized SCARA robots to assemble electronic components and polishing robots to complete delicate parts. Consequentially, a 20% reduction in production expenses and a substantial enhancement in product quality were achieved.

The preceding examples serve to underscore the benefits that can be obtained from incorporating these advanced robotic technologies.

Industrial Applications of Case Studies

Integration of SCARA robots and polishing robots has revolutionized production lines in the automotive industry. To augment the efficiency and quality of their finishing and assembly procedures, a prominent automotive manufacturer, for instance, implemented these technologies. The SCARA robots were responsible for the precise assembly of intricate components, whereas the polishing robots ensured that the car bodies finished flawlessly. Additionally, production time and expenses were decreased while the quality of the vehicles was enhanced through this integration.

Achievement Accounts

A prominent manufacturer in the electronics sector streamlined their production processes by integrating SCARA robots and polishing robots. Scanning and handling tasks were handled by SCARA robots, whereas the polishing robots ensured that delicate electronic components received consistent, high-quality finishes. As evidence of the efficacy of combining these technologies, this integration led to a substantial decrease in defects and a conspicuous acceleration in production speed.

Proximous Developments and Trends

Progressions in Technology

The foreseeable future is expected to witness ongoing technological advancements in the domains of polishing robots and SCARA robots. It is expected that the functionalities of these robotic systems will be enhanced through developments in sensor technology, machine learning, and artificial intelligence. As a consequence, performance, adaptability, and precision will all increase. Potential future developments may entail improved collaboration between human and robotic operators, thereby facilitating the robots’ ability to function in greater harmony.

Opportunities for Market Expansion

Poland anticipates a substantial expansion in the market for polishing robots and SCARA robots. Demand for these sophisticated robotic systems will continue to increase as more industries adopt automation in an effort to remain competitive. Preceding themselves for triumph in a swiftly evolving manufacturing environment, organizations that allocate resources towards these technologies can anticipate enhancements in productivity, quality, and cost-effectiveness.

In summary

Major progress has been made in industrial finishing with the incorporation of polishing robots and SCARA robots. Contemporary manufacturing procedures are inextricably linked to these technologies due to their unparalleled accuracy, velocity, and dependability. Sectors can attain substantial enhancements in productivity, efficiency, and quality by integrating the advantageous features of SCARA robots and polishing robots.

The future of industrial finishing appears promising as perpetual technological progress propels innovation in robotics. Businesses operating in an ever more saturated market will gain a competitive advantage by embracing these state-of-the-art technologies. A paradigm shift in manufacturing excellence will ensue with the introduction of polishing robots and the seamless integration of SCARA technology.

Industrial sectors can enhance their success and sustainability by judiciously incorporating and adopting these sophisticated robotic systems, contingent on their comprehension of their potential and advantages. The collaboration of polishing robots and SCARA robots is what will power the future of finishing.