Source: robothalloffame.org

Today’s automated industrial sector would be far less advanced without Selective Compliance Assembly Robots. They play a major role in production processes as they are built to work fast and be precise. Modern versions are also applicable in multiple industries and a wider variety of tasks.

It thus begs the question, who had such a stroke of genius as to invent this type of robot? While there are currently many formidable SCARA robot manufacturers across the world, the design originated in Japan. Read on and let’s delve further into the humble beginnings of this great robotic invention.

Table of Contents

The Invention of the SCARA Robot

Source: researchgate.net

In 1977, the International Symposium on Industrial Robots was held in Tokyo, Japan. During this event, experts in the field had a chance to see and discuss the latest invention which was the SIGMA assembly robot. It presented new possibilities and ideas that had previously not been explored in the field.

Professor Hiroshi Makino of Yamanashi University got inspired by the ideas from the symposium. He began to research the subject further and explored new ways to improve the assembly robot. To boost his efforts, he organized the SCARA Robot Consortium which consisted of himself and 13 Japanese companies.

By 1978, the consortium had invented the first SCARA robot prototype. It was tested for usability in various industrial applications and parameters such as speed and repeatability. In 1980, the group led by Professor Makino launched a second improved version of the SCARA robot.

SCARA Robots Are Applied in Industries

Source: assemblymag.com

Among the members of the consortium were a host of manufacturers including Fujitsu and Toshiba. Following the success of the second prototype, they began to manufacture industrial scara robots in 1981. They applied them in their factories but also marketed and sold them to other manufacturers.

Sankyo Seiki, a Japan-based music box manufacturer, was one of the first firms to take on scara robots. They added them to their production line in the same year and used them to assemble PCBs for audio amplifiers. Other companies like Hirata and NEC were also among the first to own this type of assembly robots.

Modern SCARA Robots

The development of modern scara robots took on a more diversified approach than the invention of the original. Each industrial robot manufacturer now develops their own modified version with features that are unique to their brand. In comparison to older models, the average modern scara robot has:

Higher payload capabilities

Longer arm reach

Improved accuracy achieved using quality reducers

Higher speed due to improved motors

Other features like dust-proof and drip-proof materials and the availability of different end-effectors have also greatly improved scara robots. In addition to multiple mounting options, these features have made scara robots applicable in more industries than ever before.

Nevertheless, the basic operating principle of scara robots remains as Professor Hiroshi Makino designed it.

The Future of SCARA Robots

Source: robotics.org

Based on current trends in the robotics industry, here are some advancements that may occur in the manufacturing of scara robots.

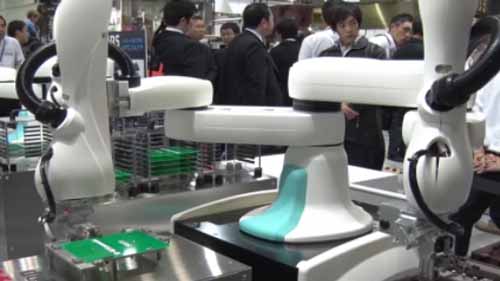

Dual-arm SCARA Robots

A dual-arm scara robot is one robot with two scara robot arms mounted on one base. They are quite similar to a human being with two arms. They are currently a novel concept as not many robot manufacturers produce them. However, given their high productivity and numerous advantages, they will likely become a mainstay in the industry.

Easily Programmable SCARA Robots

Whereas programming and controlling scara robots in the past often required skilled labor, that may soon change. The emergence of easy-to-use pre-installed software and teachable scara robot arms fitted with vision sensors may make programming unnecessary. Moreover, both of these methods are easy to use and require no special skills.

Affordability

The initial models of scara robots cost millions of Yen in Japan. Robot components were hard to find and therefore expensive. That has since changed and manufacturers are now focusing on low-cost scara robots as well to accommodate more customers.

Collaborative Features

In most factories, human workers are increasingly sharing workspaces with robots. There have been significant strides in ensuring that such work environments are safe for staff. Collision sensors and round-edge robot designs are some of the precautions currently offered by robot manufacturers. Nonetheless, they are not full-proof and it will be interesting to see what other options developers will offer to address this challenge.

Conclusion

The world certainly owes a debt of thanks to Professor Hiroshi Makino for his stewardship in the invention of the SCARA robot. While the efforts of robotic arm manufacturers can not be negated, it is his commitment and vision that made SCARA robots a reality.