Source: Pinterest

Factories and industries use industrial manufacturing robots to automate their processes. Industrial Robots are automated to emulate human actions. An industrial robot works in the same fashion as a human arm does. However, a factory robot arm is a hundred times more efficient than manual labor. This is because a high-speed robot arm is programmed to carry out multiple tasks at one time and doesn’t get tired at all. Many industries are now leveraging automated robots because of their systematic working.

When it comes to using automation in factories, there are many robot applications in manufacturing, assembling, packing, sorting, etc. Every industrial robot manufacturer is well aware of the wide variety of tasks robots are expected to do, which is why various kinds of robots are manufactured. Here are some of the main robots you can find in the automation industry.

Table of Contents

Cartesian Robots

Cartesians are the most common type of robots. They are frequently used in different industries. A cartesian robot is also known as rectilinear or gantry. The three axes X, Y, and Z of the cartesian robot move in an orthogonal direction and provide linear motion. Cartesian robots are highly popular in plant industries. It is because plant operators prefer them for their flexibility and customizability. Cartesian robots have various applications such as pick and place operations, assembling, loading, unloading, and the functions related to adhesives.

Source: Pinterest

Cylindrical Robots

Cylindrical robots work quite similarly to cartesian robots. Cylindrical robots have two joints; rotatory and prismatic. Rotatory joint provides rotational motion and a prismatic joint provides linear motion along the axis. Cylindrical robots are mainly used in the transportation of delicate and heavy items such as LCD Panels. They also provide easy application, installation, and organization. Cylindrical robots also require less floor space, hence these advantages make cylindrical robots a necessary technology for big industries.

Source: Google

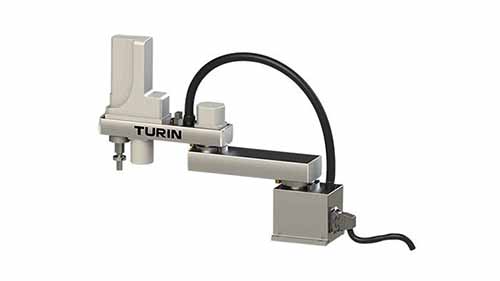

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are considered the most systematic robots. It is because SCARA robots offer x,y,z axes along with the rotatory motion. Scaras contain the features of both cartesian and cylindrical robots and are faster than the two. The SCARA robot design features a more convenient integration system than the cartesian and cylindrical roots. SCARA Robots are mainly used for assembly applications, packaging, pharmaceutical manufacturing, palletizing, semiconductor handling, and loading.

Source: Pinterest

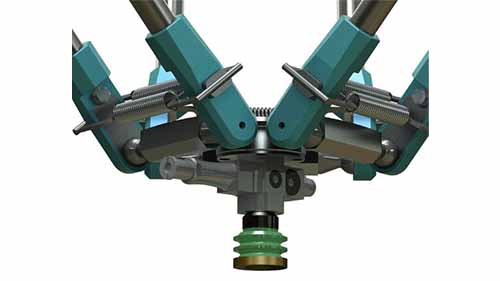

Delta Robots

Delta Robots are considered the most expensive and fastest robots in the automation industry. Delta robots are also known as Parallel Link Robots because they consist of parallel joints connected at the base of the robot. The most common application of delta robots is as a pick and place roboter. They provide accurate precision and because of their quick speed, Delta robots like automatic pick and place robots, are highly popular in numerous industries. Food industries, automobile, electronic, and pharmaceutical industries are some of the industries that leverage Delta robots.

Source: Pinterest

Articulated Robots

An articulated robot is basically a robotic arm. The arm is joined to a base which can have two to ten joints attached to it. The joints can either be orthogonal or linear in shape. Articulated robots require less floor area, provide high speed, and with the help of its planes can perform multiple actions at one time. Articulated robots are used in food packaging, automotive assembling, machine manufacturing, welding materials, steel, and glass handling. You can find many robotic arms for sale quite easily.

Source: Pinterest

Polar Robots

Polar Robots have two rotatory and one linear joint that connects the arm to the base of the robot. They are also known as Spherical Robots. The arm of a polar robot is rotatable and highly elongated and is suitable for use in most workspaces. The extended arm makes it easier for polar robots to reach above and below the areas that require work. Polar robots also require less floor space as the base is smaller than the arm. Polar robots are mainly used in the process of die casting, stacking and unstacking the products, welding, glass, and material handling.

Maintenance and Safety Measures Required for Industrial Robots

The best way to protect industrial robots from breakage is to create a fence around them. The fence around the robot functions as a guard that when opened; signals the robot to stop working. The fence provides protection to the operator as well as the robot.

The maintenance of robots generally depends on the kind of environment in which they are kept. For example, if a robot is kept in an environment where it is constantly being exposed to dust and dirt, it will require frequent cleaning by a professional.

Source: Google

Conclusion

If you are looking to invest in an industrial robot, make sure that you consider your requirements. Do you need a simple pick and place robot arm or a full-fledged welding robot? Each robot comes with a set of specifications and functions, and you need to consider which match your requirements. Factors such as precision, accuracy, load, assembly, orientation, and floor space should be considered accordingly.