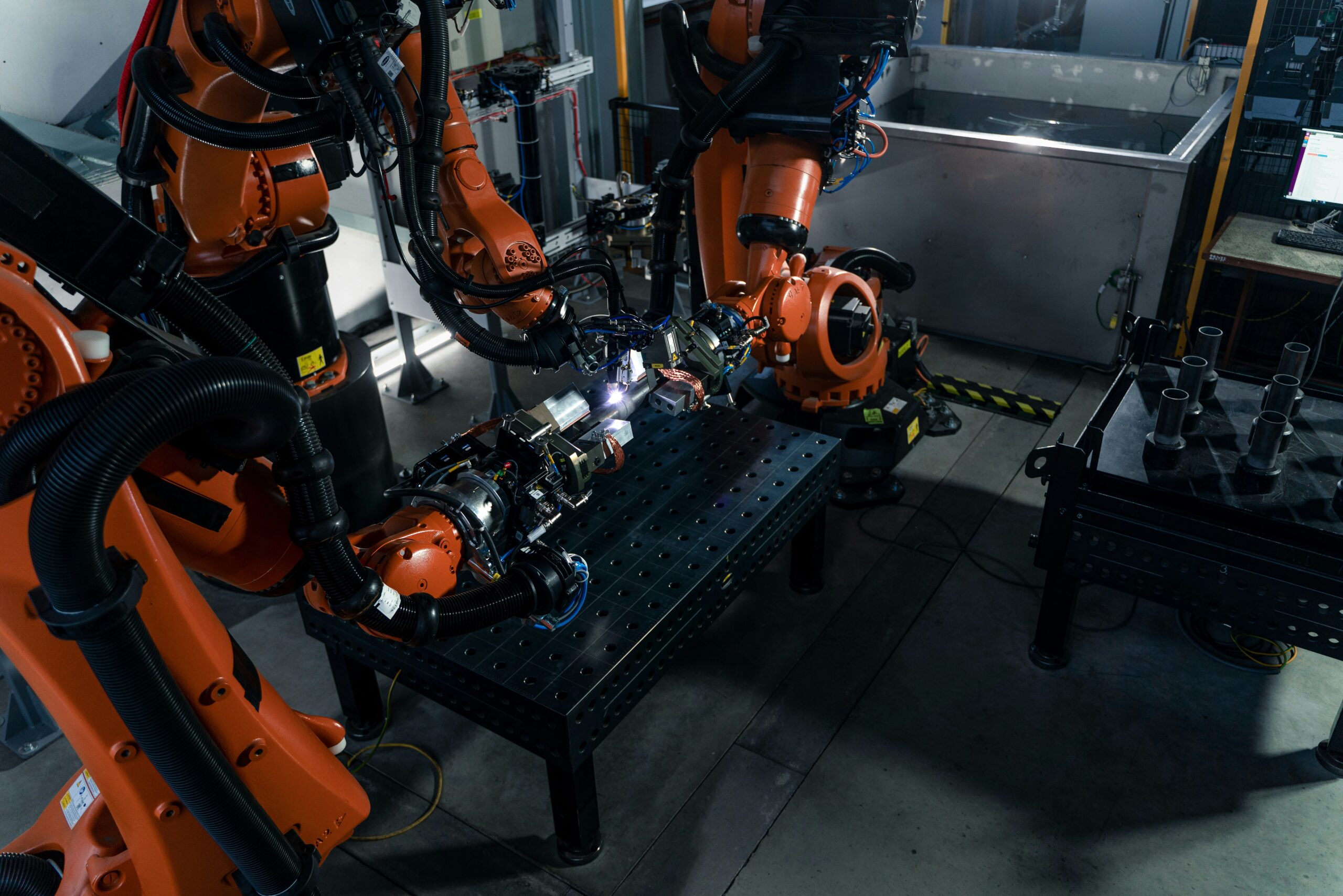

There has never been a more intensive pursuit of efficiency, accuracy, and adaptability in the large and constantly changing field of manufacturing. In this quest, one notable example of innovation is the use of specialist robots into production lines. With their respective specialties, polishing and SCARA robots combine to provide a powerful force in the automation of production operations. The QJR20-1600 robotic arm and the EVS3-400 SCARA robot represent state-of-the-art developments in their respective domains and demonstrate the possibilities of such integration.

Gratitude SCARA Robots and Polishing Robots

Defining Polishing Robots

Polishing robots, which offer unmatched uniformity and quality, have completely transformed the factory finishing process. These robots, which are made to carry out complex polishing activities, guarantee that items satisfy the highest requirements of surface finish, which is essential in sectors where surface integrity and aesthetic appeal are crucial.

SCARA Robots: An Overview

SCARA robots, on the other hand, are focused on handling and assembly activities requiring great speed and precision. One of the best SCARA robots is the EVS3-400, which has a small, flexible construction that makes it perfect for applications requiring quick and precise manipulation in a small workspace.

Technical Details and Requirements

Robot EVS3-400 SCARA

The accuracy and agility of the EVS3-400 SCARA robot make it stand out. With a maximum reach of 400mm and a payload capacity of up to 3kg, it performs very well in industries requiring exact precision, such as material handling and 3C product assembly.

Robotic Arm QJR20-1600

On the other hand, the QJR20-1600 robotic arm offers power and adaptability. With its 20kg payload and 1668mm reach, it may be used for many jobs, such as handling, palletizing, and most importantly, polishing, where its repeat positioning precision of ±0.05mm guarantees excellent surface finishes.

Combining SCARA Robots with Polishing Robots for Synergistic Automation Solutions

A synergistic effect between polishing robots and SCARA robots improves production lines’ productivity and quality. With this combination, producers can use the specific skills of polishing robots for finish processing and the high-speed accuracy of SCARA robots for material handling and assembly, resulting in products that are both internally sound and outwardly faultless.

Case Study: Manufacturing of Stainless Steel Cookware

The strength of this integration is demonstrated by a case study on the manufacture of cookware made of stainless steel. The use of QJRB20-1 polishing robots in conjunction with SCARA robots on the production line yielded noteworthy enhancements in productivity and product caliber, therefore showcasing the capacity of these technologies to transform manufacturing procedures.

Advantages of Including Robots in Manufacturing

Enhanced Productivity

When polishing robots and SCARA robots work together, manufacturing schedules may be accelerated dramatically while maintaining quality. This efficiency is critical in sectors of the economy where demand is subject to sharp fluctuations and quick adjustments to production rates are essential.

Adaptability and Flexibility

Furthermore, the integration of these robot kinds improves the manufacturing lines’ flexibility and adaptability. Because polishing robots and SCARA are so adaptable, manufacturers may readily reorganize their operations to fit changing goods or processes.

Prospects for Robotics Integration Trends and Technological Developments in the Future

As artificial intelligence and machine learning continue to progress, robotics in manufacturing appears to have a bright future. These developments might lead to even higher degrees of accuracy and autonomy. These advancements have the potential to improve the efficiency and intuitiveness of the integration of various robot kinds.

Increasing the Number of Applications

The uses of robotics technology are expected to grow and go beyond conventional manufacturing duties as it continues to advance. The combination of polishing robots and SCARA, for instance, may find new applications in industries ranging from consumer electronics to healthcare, demonstrating the adaptability and promise of these technologies.

Conclusion

An important development in the automation of production processes is the integration of SCARA robots with polishing robots. Manufacturers may now obtain previously unachievable levels of efficiency, quality, and flexibility by utilizing the unique capabilities of each type of robot. It is certain that the potential for these kinds of connections will only increase in the future, influencing the production environments of the future.

The message to manufacturers is clear: integrating polishing robots and SCARA robots is not just a choice, but a must for companies hoping to stay competitive in a market that is changing quickly. Manufacturers may achieve unprecedented productivity and creativity by investigating the newest advancements in robotics technology and consulting with experts to ensure successful deployment. Production has entered a new era that is automated.