Source: dilx.co

Most spheres of business turn to automation when they need to streamline their operations. It was, therefore, only a matter of time before warehouses joined the fray. More so, given the tough balancing act that is managing a warehouse.

Automated warehouses rely heavily on technological innovations to run their operations. Such innovations include warehouse management software and warehouse robots. Some warehouses use one method of automation while others integrate different kinds all at once.

How do these warehouse automation systems work though? Do they really solve warehousing challenges? Read on and let’s explore further.

Table of Contents

Physical Warehouse Automation

Source: m.noah-yc.com

Physical warehouse automation refers to the use of warehouse robots to manage inventory in a warehouse. Such management involves :

Unloading packages

Recording intake

Systematically arranging the packages

Retrieving specific packages to fulfill orders

These are all labor-intensive tasks that take hours to accomplish when done manually. It is from this dilemma that the need for physical warehouse automation emerges.

Types of Warehouse Robots

There are different types of warehouse robots recommended for various warehouse applications. They include:

Articulated robot arms – these are jointed robotic arms that are flexible and can be programmed to unload, sort, and arrange packages. They are often compatible with warehouse software. A good warehouse robot manufacturer can also customize them with sensors and other provisions to match the needs of your warehouse.

Good-to-person technologies – they are used to collect packages and deliver them to warehouse staff as opposed to employees transversing the warehouse carrying loads. Examples of GTP technologies include Automated Guided Vehicles(AGVs), Automated Storage and Retrieval Systems(AS/RS), and Autonomous Mobile Robots(AMRs).

Unmanned Guided Vehicles – also commonly known as drones. They are applicable in ferrying lightweight loads among other inventory handling tasks.

How Do They Work?

Automated warehouse robots have in-built computerized systems that are linked to a collective warehouse software. It is through this software that staff can communicate with the robots to prompt them to perform different tasks. Their movements are guided using sensors. This excludes AGVs that require a path charted out for them using a magnetic strip.

On the other hand, articulated robot arms are often programmed individually for specific tasks. They too can be fitted with sensors to guide them in sorting and arranging packages. However, unlike automated robots, they handle inventory from a stationary position.

While warehouse robots are fundamentally designed to transport packages within a warehouse, they also have other supportive features. For example, drones and AMRs can identify packages using RFID sensors. As such, they can be used for more than just ferrying packages but other tasks too like stock-taking and sorting inventory.

Choosing the Right Robotic Warehouse Automation

Source: evsrobot.com

The size of your warehouse and the types of operations that happen there will determine what kind of automation is ideal. AS/RS, for instance, is recommended for large warehouses. It would be an overkill solution for a small warehouse. Small to mid-level warehouses are better suited by options like Autonomous Mobile Robots that are not too predicated on operational scales.

Consider the nature of the tasks you would like to automate as well. An articulated robot arm, for example, could handle higher payloads and work faster at loading and unloading than automated robots. Suffice to say, there is not a perfect one-fits-all solution for physical warehouse automation. The trick is to match the right robot to a suitable task.

Digital Warehouse Automation

Source: veridian.info

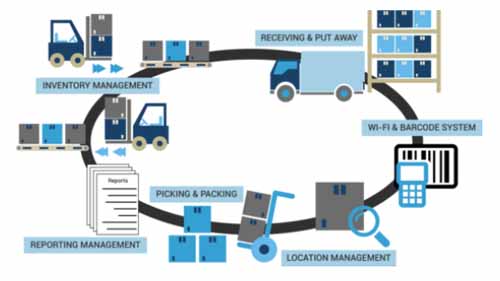

Digital warehouse automation is also referred to as digital process automation or warehouse automation software. It is the use of uniquely designed software to handle inventory in a warehouse. Ideally, from the moment inventory is received until it is dispatched, there should be a record of it in the warehouse automation software.

An example of a warehouse management software is the Enterprise Resource Planning system.

How Does it Work?

Source: Pinterest

Warehouse Management software works as a database of warehouse data. It typically has a record of all items, their storage location, and when they were received at the warehouse. It could also contain other details such as expiry dates which are essential in managing inventory.

However, the data has to be collected for it to appear on the database. This can be done using methods such as:

Mobile barcode scanning – employees use a mobile barcode scanner to scan the barcode details of inventory and then it is automatically uploaded to the warehouse software.

Automated data collection – drones or AMRs with RFID sensors are used to scan inventory and update data in real-time. It is easy and can be done every day.

Choosing the Right Digital Warehouse Automation

Source: Pixabay

The scope of data you intend to keep and the nature of your operations will guide you in choosing the right warehouse software. It is also advisable to consider if the software you choose will be compatible with warehouse robots.

Conclusion

When the right tools of warehouse automation are used, an automated warehouse runs smoothly and is much cheaper to maintain. If your warehouse is still running manually, it may be time to reach out to warehouse robotics companies and see what they have to offer.

Also Read: