Introduction to Six-Axis Robots in Pick and Place Automation

Six-axis robots have revolutionized industrial automation. They are highly advanced machines that redefine efficiency and precision, particularly in pick and place operations. The XR18-EX-138S 6 Axis Collaborative Robot Arm can handle, palletize, and even perform complex tasks like arc welding, making it a useful tool in a variety of industrial settings. Its impressive 18 kg payload and 900mm reach make it one of the most remarkable examples of the advanced capabilities of six-axis robots.

Features and Advantages of the XR18-EX-138S in Automation

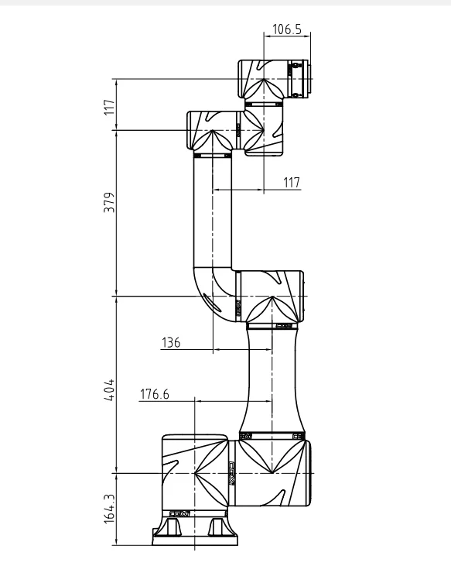

The XR18-EX-138S six-axis robot stands out with its technical prowess. This robot’s excellent repeat positioning accuracy of ±0.03mm and its large armspan of 900mm enable it to execute with unparalleled precision. Its six joints provide a wide range of motion, allowing it to accomplish difficult jobs with ease. Such features make six-axis robots ideal for pick and place applications where accuracy and reach are crucial. The XR18-EX-138S’s capacity to handle payloads up to 18kg further extends its applicability across various industrial tasks.

Collaborative Aspects of Six-Axis Robots

Modern robotics relies heavily on collaboration, and the XR18-EX-138S is a prime example of this. Six-axis robots are collaborative because they free up human workers from risky and repetitive jobs, which is vital in today’s production environments. They are designed to securely function alongside human operators, even in confined places, which boosts workplace productivity and safety. Such collaborative features ensure that these robots can be seamlessly integrated into existing workflows, augmenting human efforts rather than replacing them.

Technical Innovation in Six-Axis Pick and Place Robotics

The XR18-EX-138S reflects the pinnacle of technical innovation in six-axis robots. Its joints can move at impressive speeds, with the end-of-arm (EOA) reaching a maximum speed of 3m/s, ensuring swift and efficient operation. The robot’s absolute positioning accuracy and high-frequency control bus underscore its ability to perform precise operations consistently. The robust aluminum alloy XR18-EX-138S is built to withstand a variety of operating environments, and it is more than simply a robot—it is a monument to the progress made in pick and place robotics.

Six-Axis Robots in Diverse Industrial Applications

Because of their adaptability, six-axis robots, like the XR18-EX-138S, are useful in many different industries. For instance, in the automobile industry, they are used to precisely and swiftly assemble complex parts. In electronics, where delicate handling is paramount, these robots deftly manage sensitive components. The food and beverage industry benefits from their hygienic and precise operations in packaging and handling tasks, ensuring compliance with stringent health standards. The XR18-EX-138S’s unique combination of strength, reach, and accuracy makes it an asset across these diverse sectors, showcasing the expansive role of six-axis robots in modern industry. Six-axis robots are indispensable because of their accuracy in moving large, heavy things, even in more demanding industries like logistics and metallurgy. They are especially important in the pharmaceutical business, where error margins are almost nonexistent.

Cost-Benefit Analysis of Implementing Six-Axis Robots

Considerations such as reduced labor costs, quicker production, and lower mistake rates can help achieve a positive return on investment (ROI). Other important considerations are energy usage, maintenance costs, and integration charges. Six-axis robots, like the XR18-EX-138S, are an investment that requires careful consideration. Long-term benefits in efficiency, productivity, and precision often outweigh these costs.

Future Outlook for Six-Axis Robots in Automation

Six-axis robots in automation are predicted to be more deeply integrated with emerging technologies in the future. Artificial intelligence and machine learning advances will likely provide robots such as the XR18-EX-138S with improved decision-making and adaptive learning skills, allowing for more autonomous operations. Advanced sensor technology will likely also increase the precision and environmental awareness of these robots, enabling more complex and responsive operations. Additionally, as Industry 4.0 and smart factories gain traction, six-axis robots will play a key role in building data-driven, networked production environments. Moreover, the ability of these robots to work more easily with other automated systems and Internet of Things devices will likely boost productivity and efficiency even further. These developments hold the promise of opening up new possibilities and uses for six-axis robots, confirming their status as the foundation of industrial automation and accelerating the transition to more intelligent, responsive, and efficient manufacturing processes.

Conclusion

Six-axis robots, particularly those exemplified by the XR18-EX-138S, are revolutionizing the field of pick and place automation. Their blend of versatility, precision, and collaborative potential makes them invaluable assets in the modern manufacturing environment. As technology continues to advance, the capabilities and applications of six-axis robots are only set to expand, promising a future where efficiency and automation go hand in hand in driving industrial innovation and productivity. Visit EVS Int for more information!