Introduction

Profound transformations have taken place within the manufacturing industry due to the progress made in robotics. In numerous industries, robotics in manufacturing has increased output, precision, and adaptability, from quality control to assembly lines. SCARA robots, renowned for their dexterity, precision, and velocity, have become indispensable elements within the domain of industrial robotics. Through a comprehensive examination of the EVS3-400 model, this article explores the transformative implications that SCARA robots bring about in contemporary manufacturing operations.

Progress of Manufacturing Robotics

Early in the 20th century, with the introduction of automated assembly lines, the journey of robotics in manufacturing commenced. Predominantly engineered to perform monotonous duties, these early robots increased output rates by eliminating the need for human labor. The precision and adaptability necessary for more complex tasks were, however, lacking in these machines.

The capabilities of industrial robots progressed in tandem with scientific development. In the 1950s, the introduction of computer numerical control (CNC) machines, which enabled more precise and automated regulation, rendered significant strides in the evolution of manufacturing processes. In addition to robotic inspection and assembly, welding, and painting, factories were performing a wide variety of tasks during the 1980s.

Robotics in manufacturing today encompasses a broad spectrum of technologies and applications. Due to their distinctive amalgamation of velocity, precision, and adaptability, SCARA robots have emerged as essential tools in numerous sectors. By enabling increased levels of quality control and productivity, these robots have revolutionized manufacturing processes.

SCARA Robots: An Overview

An industrial robot referred to as SCARA is distinguished by its X-Y axis selective compliance articulated robot arm. The vertical axis rigidity of SCARA robots is preserved while they execute precise lateral movements due to this design. Therefore, assembly, packaging, and material handling are examples of tasks that necessitate both speed and precision.

SCARA robotic systems offer several advantages over Cartesian and articulated robots, among other industrial robot configurations. Cartesian robots exhibit reduced flexibility in the execution of complex tasks on account of their dependence on linear motion. SCARA robots are more precise than articulated robots, which operate at a slower speed despite possessing a greater number of degrees of freedom. SCARA robots provide an adaptable resolution for an extensive range of manufacturing tasks due to their unique configuration that strikes a harmonious equilibrium between these two extremes.

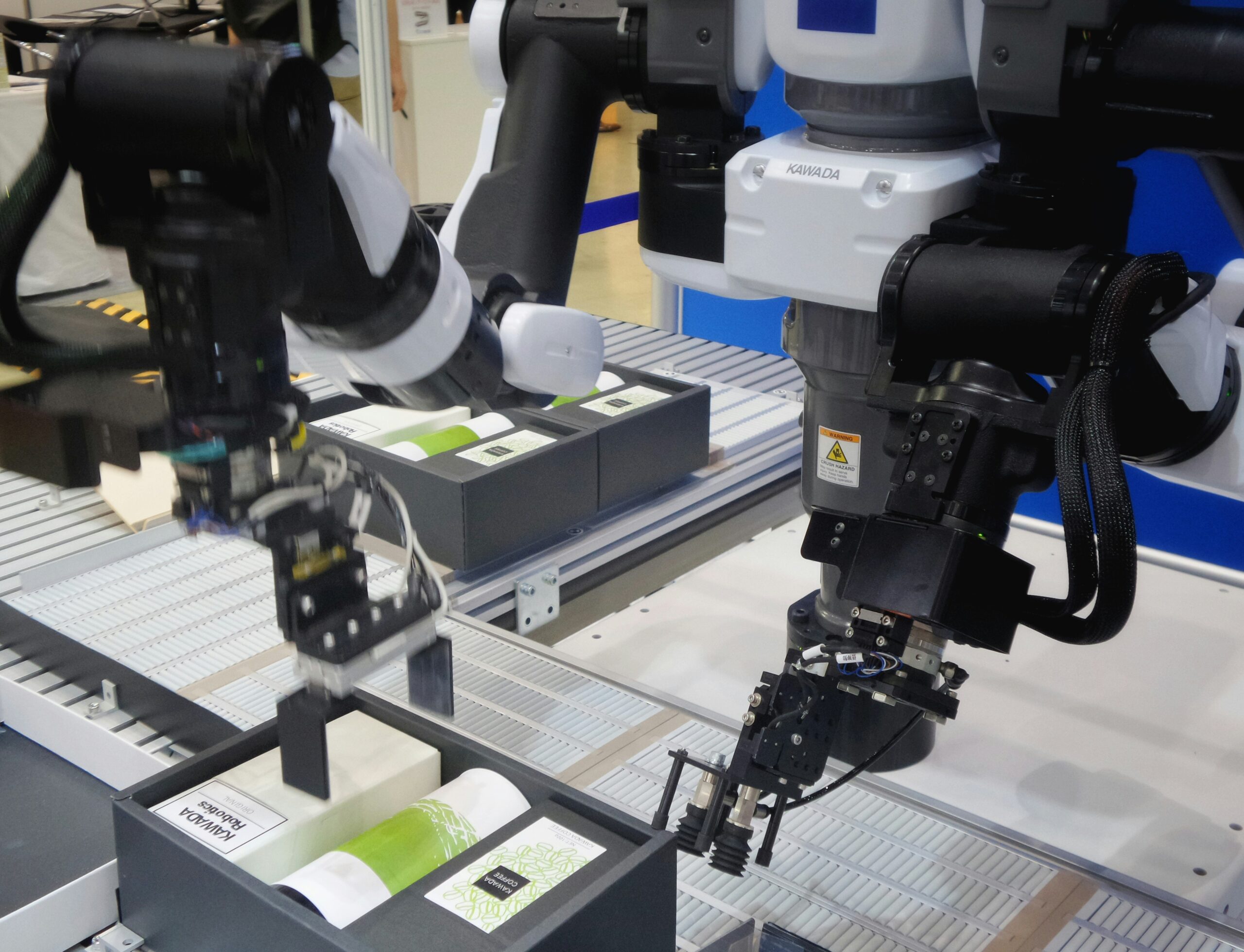

Modern Manufacturing Utilizing SCARA Robots

With their manifold benefits, SCARA robots have emerged as a fundamental component of contemporary manufacturing. They are most suitable for tasks that demand both efficiency and accuracy due to their rapid operation and precise motion. Simplified pick-and-place operations are indistinguishable from intricate assembly tasks; SCARA robots are additionally exceptionally versatile.

The lightweight EVS3-400, which features a compact and flexible structure, is a noteworthy illustration of a SCARA robot. With a maximum reach of 400mm and a payload capacity of 3kg, the EVS3-400 possesses noteworthy technical attributes. Its versatility extends to handling, palletizing, and assembly, among other applications, due to these qualities.

EVS3-400 is the product detail.

3 kg of payload

Reach Max: 400 millimeters

Slim and adaptable construction

Vibration-free operation at a rapid speed with precise transmission

Packaging, assembly, and handling 3C products are examples of applications.

It is ideal for small-scale manufacturing environments due to the EVS3-400’s ability to tighten spaces due to its compact design. Low noise operation renders it appropriate for implementation in noise-sensitive environments, whereas high transmission accuracy guarantees precise movements. The robot’s versatility and efficacy in diverse manufacturing applications are enhanced by the combined contribution of these features.

Particulars of the EVS3-400 Instrumentation

It is crucial to examine the EVS3-400’s technical specifications in order to comprehend its complete capabilities. A broad spectrum of operations and motions is feasible due to the SCARA robot‘s four axes of motion. The precise execution of tasks that demand meticulous attention to detail is ensured by its repeated positioning accuracy of ±0.01mm.

Detailed Analysis of Technical Specifications:

Four in total

Positioning Repetitive (0.01mm on the first and second axes, 0.01mm on the third axis, and 0.01° on the fourth axis)

Maximum Speed: 1000mm/sec (3rd axis), 2500°/sec (4th axis), and 720°/sec (1st and 2nd axes).

360° (4th axis), ±132° (1st axis), ±141° (2nd axis), and 170mm (3rd axis) comprise the maximum operating area.

Floor-mounted robot installation shape 13 kilograms

Energy Use: 0.7 kilowatts

Environment of installation: 0°C to +45°C, 20°C to 80%RH relative humidity (no condensation), and 4.9M/S² vibration.

Implementations: material loading and unloading, assembly, sorting, and handling; vision system compatibility

The EVS3-400’s capacity to execute a diverse array of tasks with exceptional accuracy and effectiveness is underscored by these technical specifications. Suitable for dynamic and demanding manufacturing environments due to its high operating speeds and expansive operating area.

Quality Control Repercussions

The effect SCARA robots have on quality control is among their most significant contributions to manufacturing. The consistent quality of products is effectively mitigated by the accuracy and dependability of these robots. SCARA robots play an indispensable role in upholding excellence in sectors where even minor flaws can result in substantial complications.

The EVS3-400 demonstrates exceptional performance in the assembly of 3C (computer, communication, and consumer electronics) products owing to its capable handling and accurate positioning. Each product conforms to the necessary specifications due to the robot’s capacity to execute repetitive duties with minimal deviation. For the quality and dependability of the final products to be preserved, this consistency is vital.

Real-World Applications and Case Studies

The Electronics Industry Case Study 1: Palletizing and Handling

Traversing and palletizing fragile components in the electronics industry necessitates a great deal of accuracy and caution. By effectively automating the process, the EVS3-400 has decreased the risk of damage and increased productivity in this industry. Components can be positioned rapidly and precisely due to its rapid operation and precise motion, which guarantees production lines run smoothly and without interruption.

Optimization of Assembly Lines in the Automotive Industry: Case Study 2

Assembly procedures in the automotive industry must be extremely precise and dependable. Utilizing tasks that demand high precision and repeatability, the EVS3-400 has been implemented in automotive manufacturing facilities to optimize assembly lines. Consistency in product quality, increased output, and labor cost savings have all been achieved through the automation of these responsibilities.

Third Case Study: Material Loading and Sorting in the Production of Consumer Goods

Optimal operations that can be substantially enhanced through automation are sorting and material loading in the consumer goods sector. By automating these procedures with the EVS3-400, both productivity and precision have been enhanced. It is an invaluable asset in this industry due to its capacity to sort complex materials and manage a wide range of samples.

Proximous Developments and Trends

Prospective developments in technology continue to propel SCARA robots and robotics in manufacturing toward a brighter future. The incorporation of machine learning and artificial intelligence (AI), which can augment the functionalities of SCARA robots, constitutes a pivotal domain of advancement. By allowing robots to evolve and become more efficient in response to new tasks, these technologies may facilitate environmental learning.

Collaborative robots, or cobots, that operate in conjunction with human operators, are an additional trend that is quite intriguing. Given their dependability and accuracy, SCARA robots are highly suitable for this function. SCARA robots can contribute to the safety and productivity of manufacturing environments through collaboration with human laborers.

In summary

From assembly lines to quality control, SCARA robots have indeed revolutionized the manufacturing sector. The EVS3-400 model exemplifies the beneficial attributes of SCARA robots through its exceptional velocity, precision, and versatility. It is anticipated that the utilization of SCARA robots in manufacturing will expand in tandem with technological progress, resulting in additional enhancements to output, quality, and efficiency. SCARA robots will consistently occupy a leading position in this paradigm shift and exert a substantial influence on the course of the manufacturing sector.