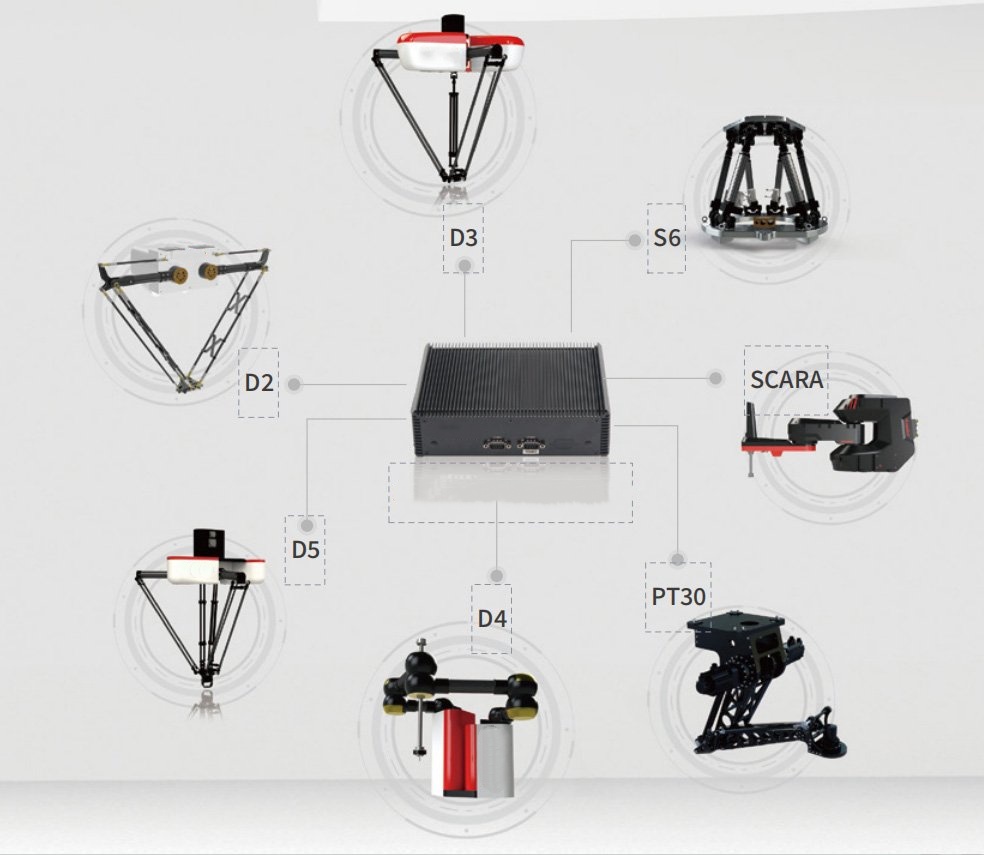

As the leading parallel robot specialist and intelligent manufacturing explorer in the industry, akes ” Free hands with

technology” as the mission to focus on the R&D and innovation of parallel Delta robot, high-speed SCARA robot and other

intelligent manufacturing technologies.

Delta Sorting Robot Arms Supplier

EVS offers high-precision and high-speed delta sorting robots, also known as spider or parallel robots in the industry, with strong rigidity. These are used in applications where products need to be picked in groups and then placed in containers or in assembly patterns. They are designed to perform dull and repetitive tasks quickly with great consistency. Aside from improving the quality and consistency of different sorting applications in the industrial field, delta robots also help in eliminating issues associated with repetitive motion injuries that can lead to mental fatigue in your employees. Choose EVS delta robotic arms and let us help you achieve a more effective production line.

EVS Delta Sorting Robot Arms Advantages

High Positioning Accuracy: EVS robots have a simple operation that can perform automatic sorting with high positioning accuracy.

Added Vision Technologies: Our machines are equipped with various vision systems and sensors to help distinguish different shapes, colors, and sizes.

Programmable Pattern: You can easily reprogram our delta robots to match your required sorting patterns in different applications.

EVS Delta Sorting Robot Arms Applications

EVS delta sorting robots are ideal for packaging and picking small and lightweight objects at high speeds in your production line. They can complete dynamic tracking, object placement, pick-up, handling, packaging, and assembly applications for food, medicines, 3C, toiletries, and others.

Under the testing trajectory (25-305-25) of international standard, the cadence can be stabilized at a maximum of 600 cycles/min. An individual robot can save 3 ~ 5 workers and replace 2~4 conventional sorting equipment.

Even under the condition of high speed (over 300 cycles/min), the precision can still reach ±0.02 mm. It is more applicable to high-precision sorting and assembly under the condition of high speed.

It is of high-precision sliding Hooke joints, and by giving consideration to high precision, high applicability and specialization, and measured wear- resistance is as long as20,000 hours. The assembly of core component parts becomes alo convenient, the load capacity is strong and service life can be up to 8 years.

The manipulator is maintenance-free throughout the year. No extra lubrication maintenance is required for each joint and pre-tensional structure is clearance free. The structural design is simple and the connection of assembly is reliable.

EVS Robotics is an industrial robot supplier providing automation solutions and support to our customers. Our products are used in industrial automation such as welding, painting, handling, palletizing, bending and polishing. And after years of development, our core technology has been widely used in different industries like Automotive, Metal Industry, Food & Beverage, Medical & Pharmaceutical and more.

Copyright ©EVS TECH CO., LTD All rights reserved.All materials not authorized may not be redirected or for other usages.