Metal Industry

Feel free to contact us on industrial robots and we will gladly answer any of your questions.

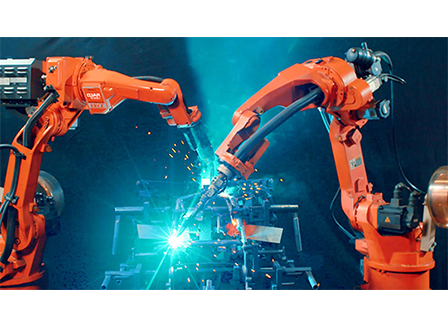

Applications for Industrial Robots in the Metal Industry

The metal industry requires a lot of demanding work and using industrial robots is a great help. They are used in handling heavy materials that are used in the assembly of construction equipment, agricultural machinery, utility trucks, recreational vehicles, and more. They are also used for more sensitive jobs, such as plasma cutting, grinding, laser cladding, and laser cutting of pipes, plates, sheets, and other metals.

EVS Robot offers ideal automation solutions for every process of your metal manufacturing company. Contact us today and start boosting your clients’ productivity with our industrial robotic arms!

Metal Industry

Flexible and Accurate Automation

The production floor involves repetitive operations that can be tiring if done manually. Automated machines can work day and night tirelessly while still maintaining accuracy and speed. They are also flexible, making it easy to adjust production lines according to materials, special products, and processes.

A Safer Work Environment

Working in the metal industry is hard work and can be dangerous. Therefore, it can be difficult for workers to be consistent, accurate, and fast. With industrial robots, workers will be safe and production cycles will continue with little to no damages, injuries, and accidents.

Improved Productivity and Fewer Warranty Costs

Metal manufacturing robots can work day and night, resulting in improved productivity. Products are also made with better quality so there will be fewer quality issues, reducing warranty costs.