Using cobot (collaborative robot) is one of the strongest trends in the industrial robot market because cobot programming is relatively easier than the traditional industrial robots, and newly emerged cobot manufacturers are making cobot prices lower than it used to be. In the next paragraph, we’d like to introduce the cobot trends-applied industry and case study.

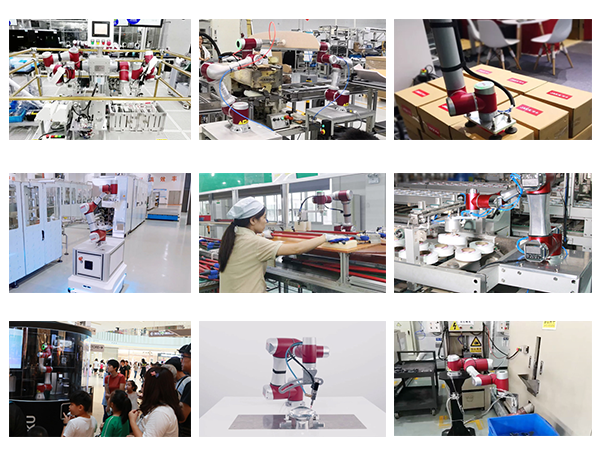

Cobots have been applied in 3C products, Automobile components, home appliances, logistics, food, daily chemical, chemical fiber textile, new energy, mechanical processing, medical equipment, LED lighting, Sanitary ware ceramics, services, etc. In 2016, the global sales of collaborative robots showed explosive growth, exceeded 10,000 units, a year-on-year increase of more than 90%, and till 2019 year-on-year increase for cobot global sales stabilized at around 30%. The main trends for cobots are as follow:

1. Cobot-AGV Work Station

Combining the collaborative robot with the AGV trolley makes the collaborative robot no longer limited to a certain unit, area, and type of work, but is upgraded to a “free robot” in the production line. It can not only carry and dispatch between various processes, but also production expansion needs to deploy robots to any work station to participate in production together, or to work collaboratively with operators in a specific safe area. Through the 5G high-speed network, collaborative robot can interact with more than ten production lines in the workshop in real-time, and understand the status information of the production line in real-time

AGV equipped with collaborative robots is mainly used for multi-station assembly and handling. Such as automated factory, computer room data management (storage server data access), power inspection, storage and sorting, automated goods supermarket, etc. In fact, because the collaborative robot is easy to install and can be quickly installed on the AGV, the collaborative robot supports modification, has a complete solution, and the collaborative robot has low power consumption, and the AGV car has long battery life.

2. Cobot-Flexible Grippers

Collaborative robots equipped with a variety of flexible grippers can complete more tasks. Compared with traditional robots, the biggest feature of collaborative robots is flexibility. In order to further improve the flexibility of collaborative robots, more and more flexible fixtures will be used in applications, and these end effectors will become more and more robots. The core component of the application, the collaborative robot can better realize some new functions after being equipped with an end effector. Under this development trend, domestic and foreign companies are increasingly emphasizing the function of collaborative robots to quickly replace fixtures. The robot can automatically replace and recognize any tool or gripper. The operator can edit the robot’s motion path through drag and drop without using a hand-held teach pendant.

3. Cobot-Medical&Health

Cobots are being increasingly utilized in the medical field, they have been supporting patient care in healthcare facilities worldwide. The newest innovation in cobot is for massage, cobot can complete all physiotherapy work, exceeding the physiotherapy level of most technicians, improving the service level of massage physiotherapy, reducing manpower investment, and improving work efficiency. In the future, it will be used in the health industry, such as hospitals, nursing homes, sports centers, fitness institutions, physical therapy institutions, rehabilitation institutions, and even families have very large application prospects.

4. Collaborative robot applications-Cobot Case Study:

If you are interested in cobot or you want to use cobots in your factory, please feel free to ask for more information.